Method for desulfurizing sodium sulfide wastewater

A sodium sulfide and wastewater technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The problem of large dosage of oxidant can achieve the effect of improving utilization rate, improving utilization efficiency and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention aims at the existing electronic electroplating wastewater and metal copper removal process. The desulfurization treatment process of sodium sulfide residual liquid has the following technical difficulties: low desulfurization efficiency, large oxide dosage, high cost, introduction of other ions is not conducive to biochemical treatment, etc. Using chemical reaction 2Na 2 S+O 2 +2H 2 O==4NaOH+S↓, provide suitable reaction conditions to make the reaction proceed in the forward direction without stopping, effectively treat sodium sulfide wastewater, high desulfurization efficiency, low input cost, only need aeration without adding others Chemical agents, green and environmentally friendly, are conducive to the further biochemical treatment of wastewater.

[0037] In the process of organic synthesis, oxygen is the most environmentally friendly oxidant. Catalytic materials are often used in organic synthesis to increase the oxidation activity of oxygen as a...

Embodiment 2

[0049] A method for desulfurization of sodium sulfide wastewater in this embodiment, the steps are the same as those in embodiment 1, wherein:

[0050] In step (A), the sodium sulfide-containing waste liquid is adjusted to pH=7.0, and the sodium sulfide waste liquid contains S 2- 50mg / L; the aeration water ratio in step (B) is 10:1, the aeration reaction time is 2h, the catalyst 3 mass content is 10%, and the reaction time is 2h; in step (C), static precipitation is 2h;

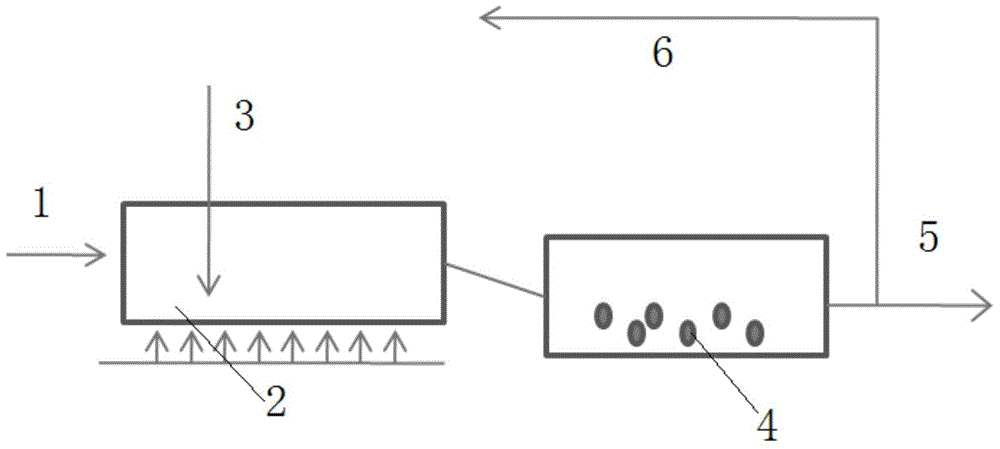

[0051] S in effluent 5 2- 15mg / L, the removal rate is about 70%, 80% of the supernatant is used to return to the front stage of the process to provide alkalinity, and the rest of the supernatant is used to enter the next sewage treatment unit 6, and the remaining in the sedimentation tank 4 The sediment is taken out and shipped out in packages.

Embodiment 3

[0053] A method for desulfurization of sodium sulfide wastewater in this embodiment, the steps are the same as those in embodiment 1, wherein:

[0054] In step (A), the sodium sulfide-containing waste liquid is adjusted to pH=6.0, and the sodium sulfide waste liquid contains S 2- 20mg / L; in step (B), aeration water ratio is 20:1, aeration reaction time is 1h, catalyst 3 mass content is 5%, reaction time is 1h; step (C) is static precipitation for 1.5h;

[0055] S in effluent 5 2- It is 10mg / L, the removal rate is about 70%, the supernatant enters the next sewage treatment unit 6, and the remaining sediment in the sedimentation tank 4 is taken out, packed and shipped out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com