pulverized coal burner

A technology of pulverized coal burner and pulverized coal pipe, which is applied in the direction of burners, burners burning powder fuel, and combustion methods, etc. Not easy to extinguish, coal combustion is stable, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

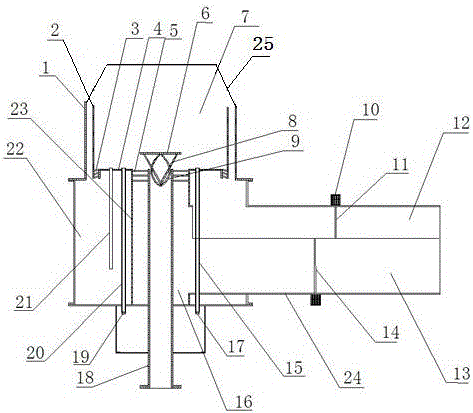

[0027] When the boiler is started, the furnace of the boiler is cleaned, the gun head of the ignition gun 21 is ignited, and the damper I11 and the damper II14 are adjusted by the electric actuator 10; the pulverized coal pipe 18 enters the coal through the primary air, and when it enters the pre-combustion chamber 7, Under the action of the coal baffle 6 and the cone 8, pulverized coal and primary air are sprayed dispersedly in the pre-combustion chamber 7; the pulverized coal in the pre-combustion chamber 7 is fully burned.

[0028] The air door I11 is adjusted by the electric actuator 10, and the air in the ignition air duct 12 enters the pre-combustion chamber 7 through the secondary air chamber 22, and provides oxygen to the pre-combustion chamber 7, so that the pulverized coal burns stably, and the furnace is combusted evenly at low temperature to achieve desulfurization. Denitrification, reducing nitrogen oxide emissions.

[0029] Through the electric actuator 10 to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com