Sand-clay mixed liner for bottom seepage proofing and crack resisting of refuse landfill

A landfill and clay technology, applied in protection devices, buildings, infrastructure engineering, etc., can solve the problems of polluting the surrounding environment of groundwater, deterioration of anti-seepage performance, and accelerated leachate leakage, etc., to achieve good underground pollution Environment, improvement of contraction potential, effect of retarding polluted underground environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

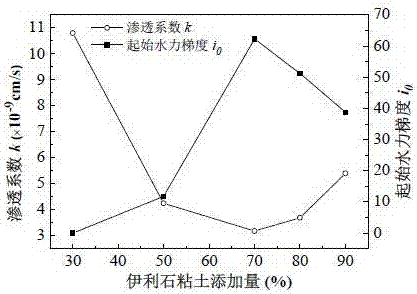

Embodiment 1

[0031] This embodiment provides a sand-clay mixed liner for anti-seepage and anti-cracking at the bottom of a landfill, which is formed by mixing sand and illite clay with an appropriate amount of water, stirring evenly, and compacting. Sand particle size distribution: fine sand 25~30%, medium sand 5~10%, coarse sand 55~60%, fine gravel 5-10%, fine sand particle size is 0.075mm-0.25mm, medium sand particle size The particle size is 0.25mm-0.5mm, the particle size of coarse sand is 0.5mm-2mm, and the particle size of fine gravel is 2mm-20mm. Illite clay is mainly illite clay, the particle size distribution is: clay 7~10%, silt 90~93%, the particle size of clay is less than 0.005mm, and the particle size of silt is 0.005mm-0.075 mm; the specific mineral composition of illite clay is: 11wt% kaolinite, 58wt% illite, 12wt% montmorillonite and 19wt% quartz. The optimal water content of the clay is 18.80wt%). Mix the sand and illite clay according to different mass ratios (define t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com