A method for retaining ore pillars in gently inclined medium-thick ore bodies with room-and-pillar method

A technology for mine houses and ore bodies, which is applied to the components of pumping devices for elastic fluids, ground mining, mining equipment, etc., and can solve the problem of large movement deformation of overlying strata, surface deformation and settlement, and large exposed area of goaf. and other problems, to achieve the effect of reducing rock burst and rock caving, ensuring stability, and ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] see Figure 5-8 As shown, a grouting device includes: a slow material box 50, including two main feed pipes 61, and a secondary feed pipe 53, the material and diameter of the main feed pipe 61 and the secondary feed pipe 53 are the same The slow material box 50 also includes a columnar slow material box 50, the slow material box 50 is hollow inside, and the feed main pipe 61 runs through the hollow slow material box 50 and is formed by the pipe body of the feed main pipe 61 outside the slow material box 50. The second filler is discharged, and the surface of the feed main pipe 61 in the slow material box 50 is equipped with a fastening sleeve body 62. The fastening sleeve body 62 is composed of at least two annular and elastic fastening ring bodies 621 and used for connecting phases. It is composed of a fastening strip 622 adjacent to the fastening ring body 621 and capable of stretching and deforming. The auxiliary feed pipe 53 runs through the slow material box 50 an...

Embodiment 2

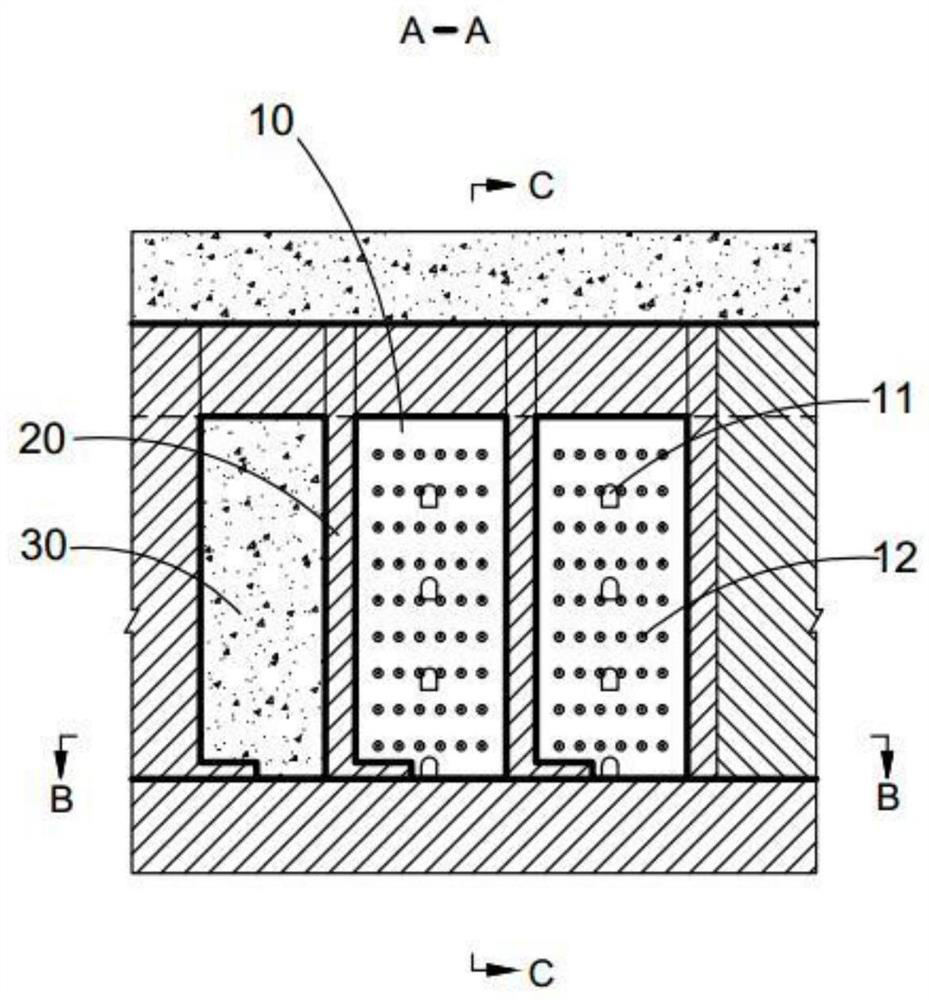

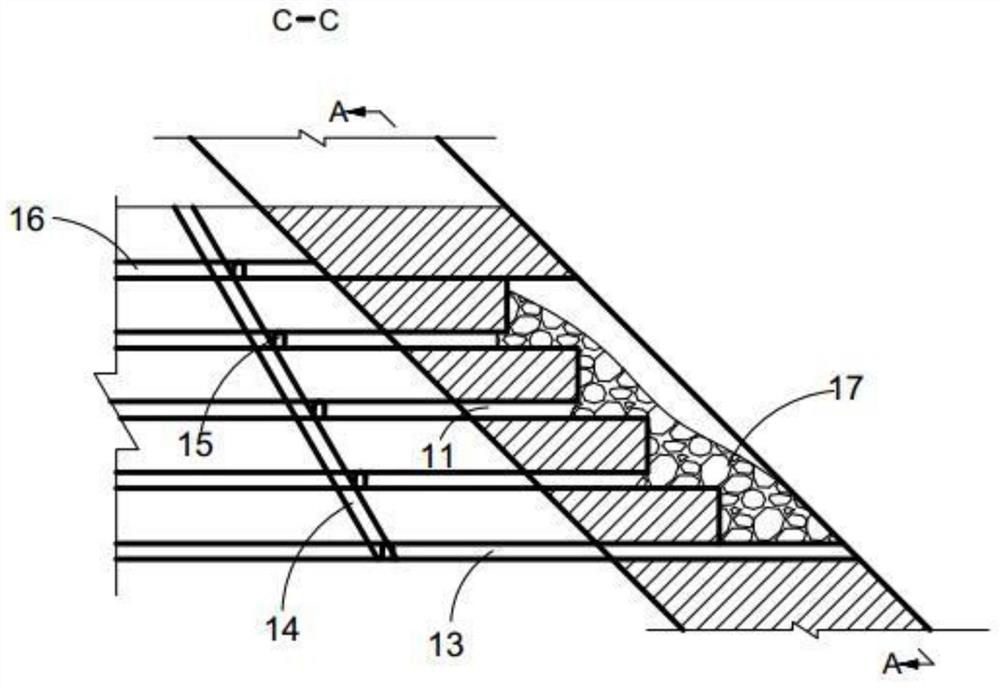

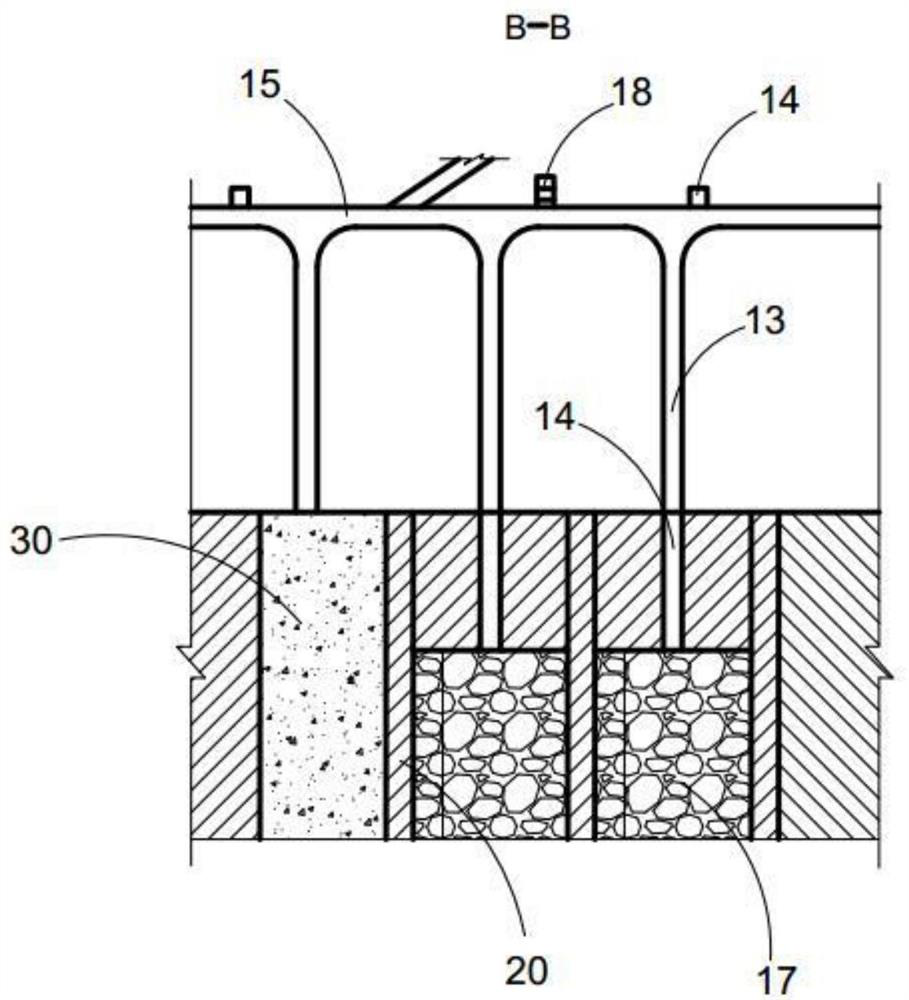

[0102] see Figure 1-3 , Shown in 10, a kind of method for retaining of the ore pillar that is used for gently inclined medium-thick ore body room-and-pillar method back mining pillar, the steps are as follows:

[0103] S10, panel area selection, select ore block vertical ore body direction layout (ore body thickness ≥ 10m), the distance between routes is 10m, divide the ore block into mine room and ore pillar, mine room width 10-15m, ore pillar width 4 -6m, in the mine room, it is divided into 5 sections along the height of the mine room, the section height is 10m, and a 7m high top pillar is reserved at the same time. Each layer is connected with the layered roadway 15 through the layered connecting road 13, wherein the mining standard project mainly includes the mining area ramp, the segmented roadway, the segmented connecting road, and the layered connecting road (mine room), sliding mine shaft, filling small shaft (mine house), filling return air shaft (mine pillar), alo...

Embodiment 3

[0115] The difference from Example 2 is that: the filler used for filling also includes 0.04 parts of allantoin; the compressive strength of the filler at 28d age is ≥37.4MPa, the failure load at 28d age is ≥828.3 / KN, and the slag is poured after the waste ore is pulverized. The cross section is rectangular slag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com