Continuous zooming infrared lens

A technology of infrared lens and zoom lens, which is applied in the field of infrared optics, can solve the problems that the best image plane deviates from the Gaussian image plane, the lens transmittance decreases, and affects the detection and recognition rate, etc., so as to improve the detection distance and imaging quality, and achieve good imaging Effect, the effect of improving system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

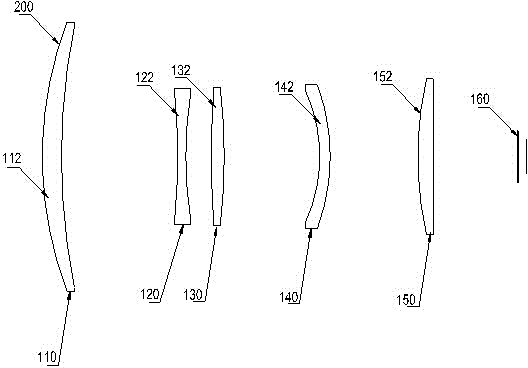

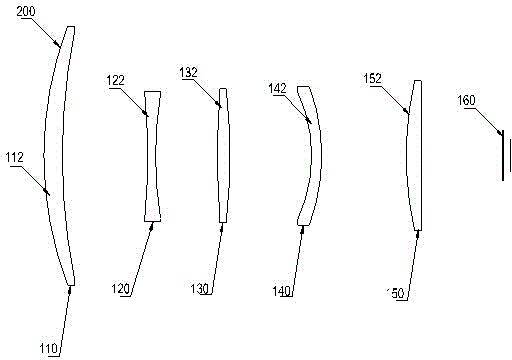

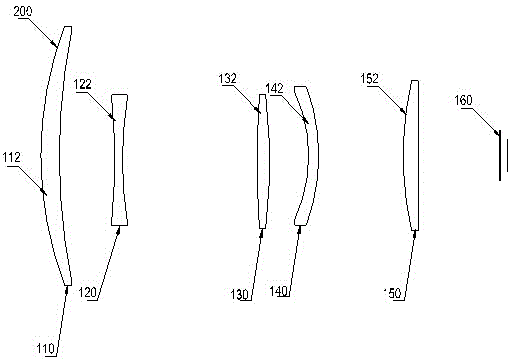

[0018] figure 1 , figure 2 , image 3 They are schematic diagrams of the zoom lens of the embodiment of the present invention at the telephoto, medium-focus and short-focus positions respectively. Figure 1-3 Among them, 200 indicates the side end of the object, and 160 indicates the side end of the image. Such as figure 1 As shown, the zoom lens of this embodiment includes: a first lens group 110 with positive diopter, a second lens group 120 with negative diopter, a third lens group 130 with positive diopter, which are arranged in sequence from the object side to the imaging side. A fourth lens group 140 with negative diopter and a fifth lens group 150 with positive diopter.

[0019] Wherein, the first lens group 110 is a front fixed group for converging and receiving light. The first lens group 110 is composed of a first meniscus germanium positive lens 112 with a positive diopter and a convex surface facing the object side. Since the lenses of the first lens group 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com