Zinc Oxide Resistor Aluminum Spraying Treatment Equipment

A zinc oxide resistor sheet and processing equipment technology, applied in the manufacture of encapsulated/cased resistors, etc., can solve the problems of physical health damage, heavy labor burden, cumbersome action process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

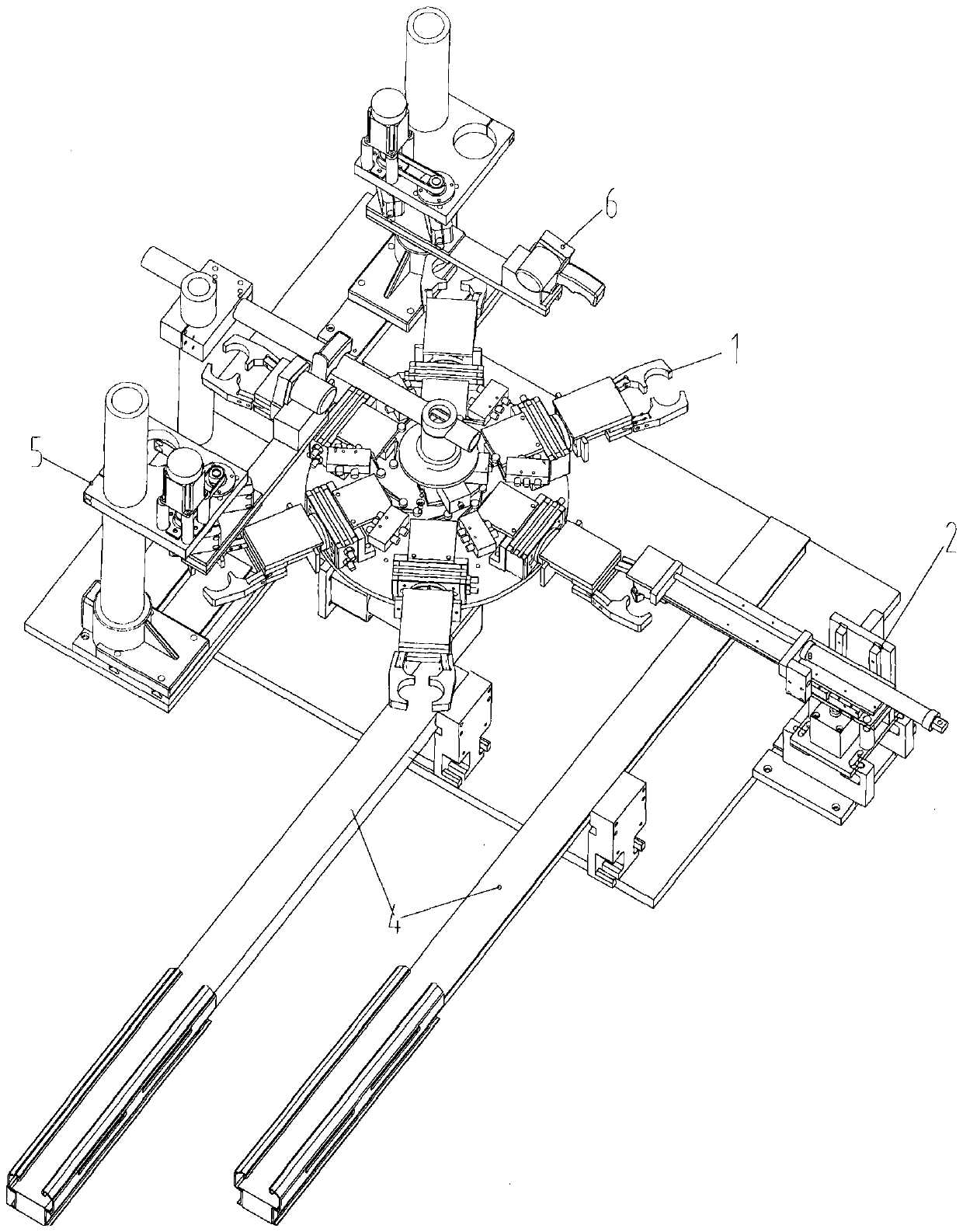

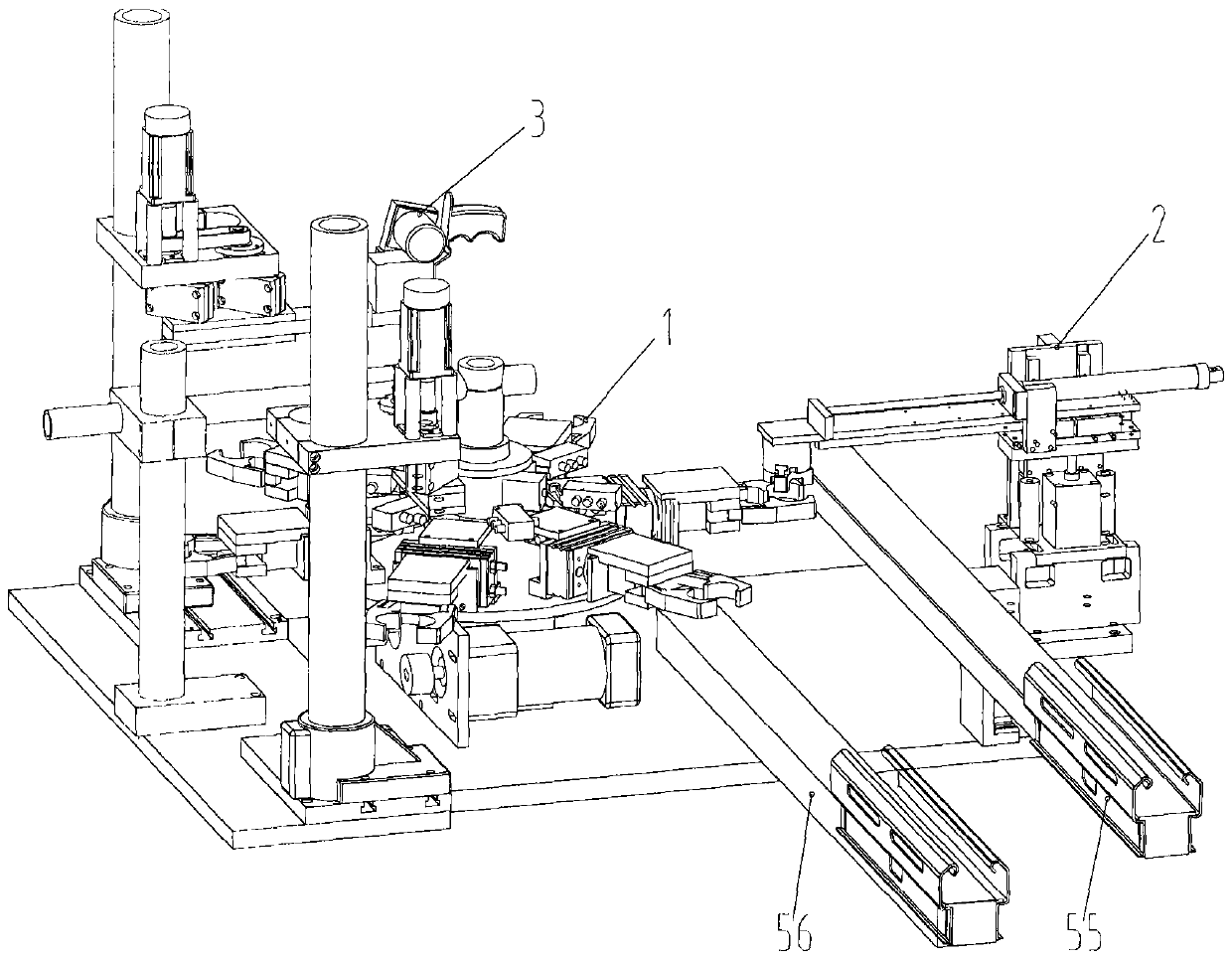

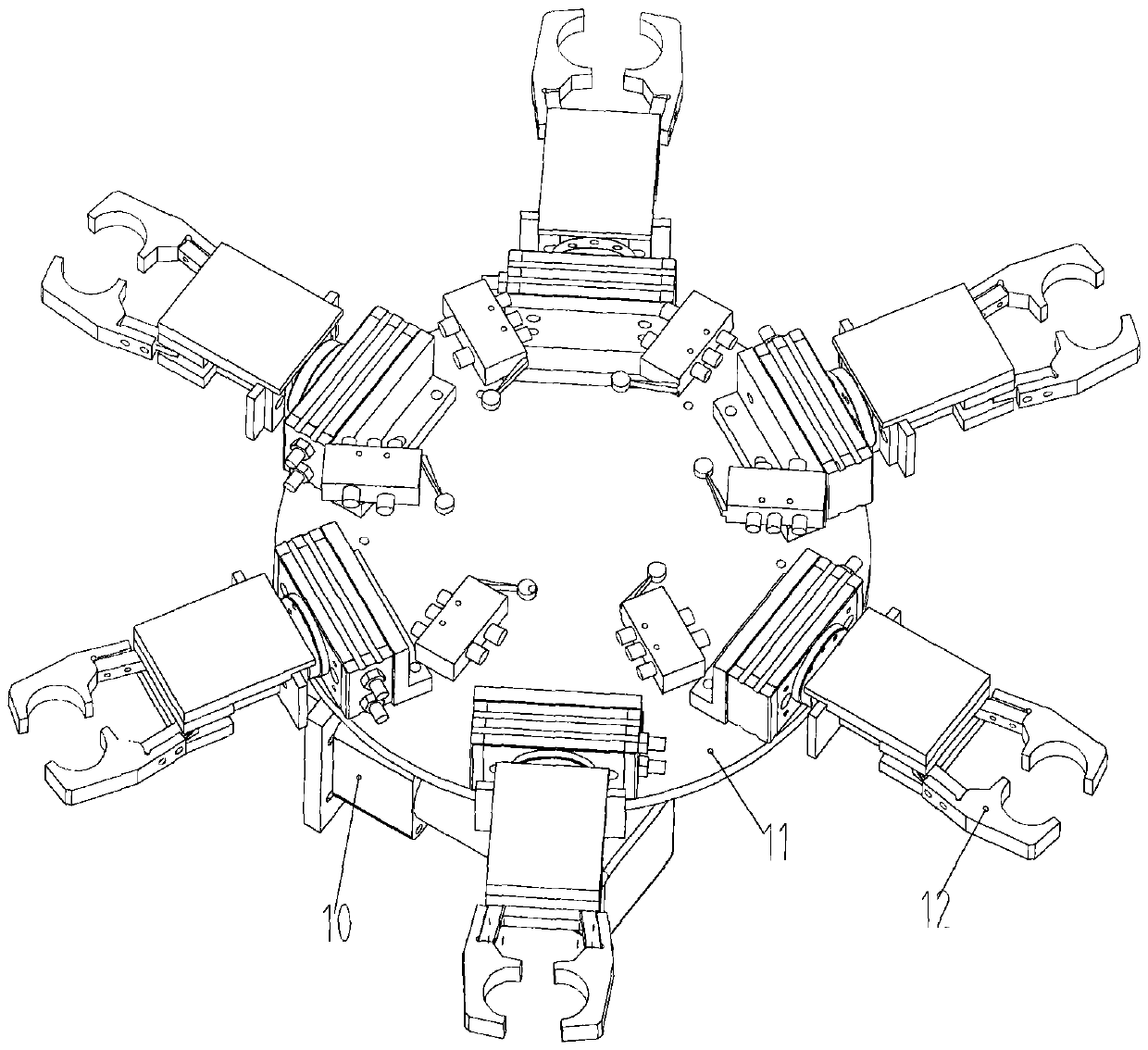

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides an aluminum spraying processing equipment for zinc oxide resistors, which is used to realize automatic aluminum spraying treatment on the upper and lower surfaces of the resistors, and make the aluminum powder content on the upper and lower surfaces of the resistors more uniform and consistent.

[0030] Aluminum spray processing equipment for zinc oxide resistors, including: clamping system 1, feeding system 2, spraying system 3, conveyor belt 4;

[0031] The quantity of the conveyor belt 4 is 2, which are respectively a feeding conveyor belt 55 and a feeding conveyor belt 56; The processed resistor sheet is transported out from the clamping system 1;

[0032] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com