Light-emitting diode epitaxial wafer and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems that the luminous efficiency needs to be improved, and achieve the effect of improving efficiency and expanding current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

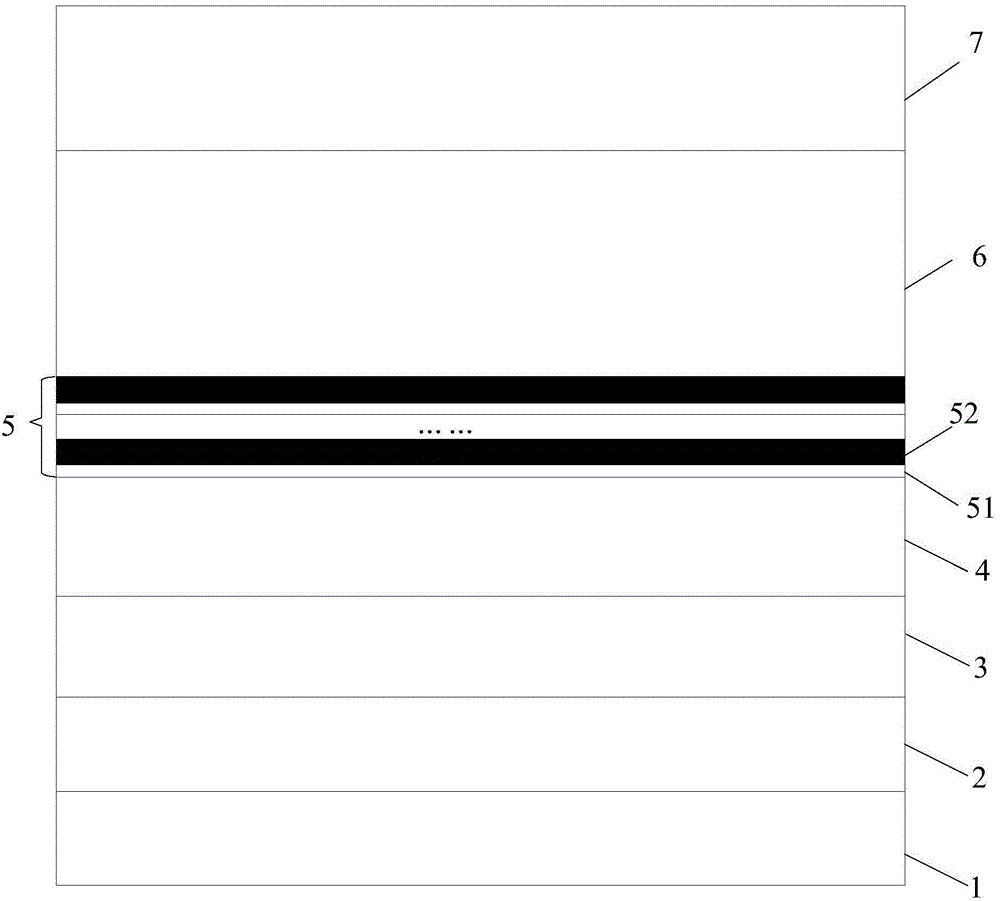

[0024] An embodiment of the present invention provides a light emitting diode epitaxial wafer, see figure 1 , the light-emitting diode epitaxial wafer includes a sapphire substrate 1, and a buffer layer 2, an undoped GaN layer 3, an N-type GaN layer 4, a current spreading layer 5, and a multi-quantum well layer 6 stacked sequentially on the sapphire substrate 1 and a p-type GaN layer 7 .

[0025] In this embodiment, the current spreading layer 5 includes alternately grown first sublayers 51 and second sublayers 52, the first sublayer 51 is formed of varistor material, and the second sublayer 52 is formed of N-type doped GaN , and the doping concentration of the second sub-layer 52 is lower than the doping concentration of the N-type GaN layer. It can be understood that if the doping concentration of the second sub-layer 52 is lower than that of the N-type GaN layer, it is beneficial for electrons to be injected into the MQW layer 6 from the N-type GaN layer 4 through the curr...

Embodiment 2

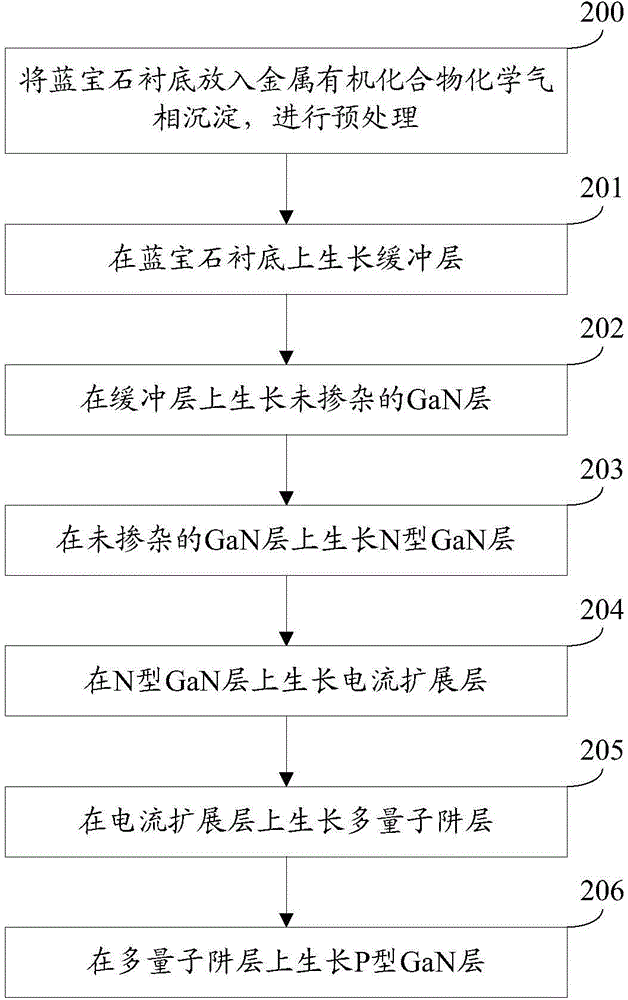

[0036] An embodiment of the present invention provides a method for manufacturing a light-emitting diode epitaxial wafer, see figure 2 , the manufacturing method includes:

[0037] Step 200: put the sapphire substrate into Metal Organic Chemical Vapor Deposition (MOCVD for short) for pretreatment.

[0038] Specifically, the sapphire substrate can be (0001) crystalline sapphire Al 2 o 3 .

[0039] Specifically, this step 200 may include:

[0040] Place the sapphire substrate in a hydrogen atmosphere for 10-15 minutes of high-temperature heat treatment at a temperature of 1000-1200 ° C to clean the surface of the substrate;

[0041] Nitriding treatment is performed on the sapphire substrate.

[0042] Step 201: growing a buffer layer on a sapphire substrate.

[0043] Specifically, the buffer layer may be a GaN layer.

[0044] Specifically, this step 201 may include:

[0045] Lower the temperature to 400-600°C, grow a GaN layer with a thickness of 15-35nm, and grow at a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com