Patents

Literature

32results about How to "Improve composite luminous efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A near-ultraviolet LED lamp with novel electron blocking layer, and preparation method thereof

ActiveCN105932130AImprove luminous efficiencyImprove injection efficiencyMaterial nanotechnologySemiconductor devicesContact layerNon doped

The invention provides a near-ultraviolet LED lamp with a novel electron blocking layer, and a preparation method thereof. A near-ultraviolet LED epitaxial wafer structure comprises a graphical sapphire substrate, a low-temperature GaN nucleating layer, a high-temperature non-doped GaN buffer layer, an n-type GaN layer, an InGaN / AlGaN multiple-quantum well active layer, a p-type AlGaN / InGaN superlattice electron blocking layer, a low-temperature lightly-doped p-type AlInGaN hole expansion layer, a high-temperature p-type GaN layer and a p-type InGaN contact layer. The electron blocking layer adopts a p-type Al<y1>Ga<1 y1>N / In<x1>Ga<1 x1>N superlattice structure. Along with the increase of the number of superlattice periods, the InGaN thickness is reduced step by step, the Mg doping concentration is increased step by step and the hole concentration is increased. By the invention, the hole injection efficiency is effectively improved and the electron hole recombination luminous efficiency is enhanced, so the near-ultraviolet LED luminous efficiency is increased.

Owner:东莞市中晶半导体科技有限公司

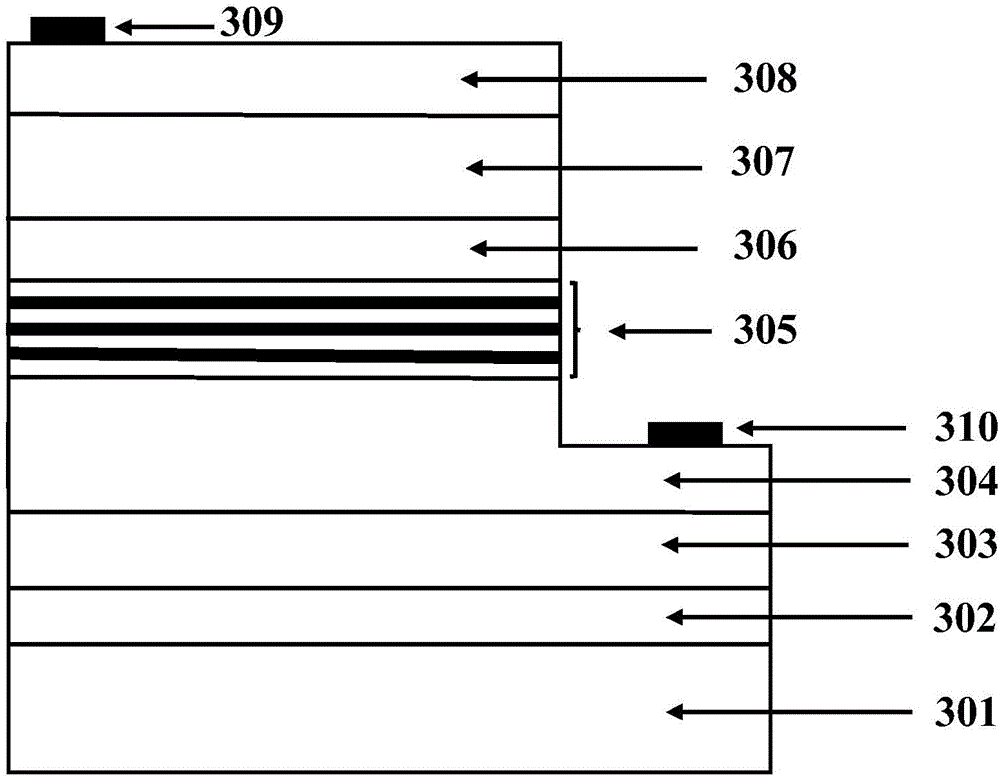

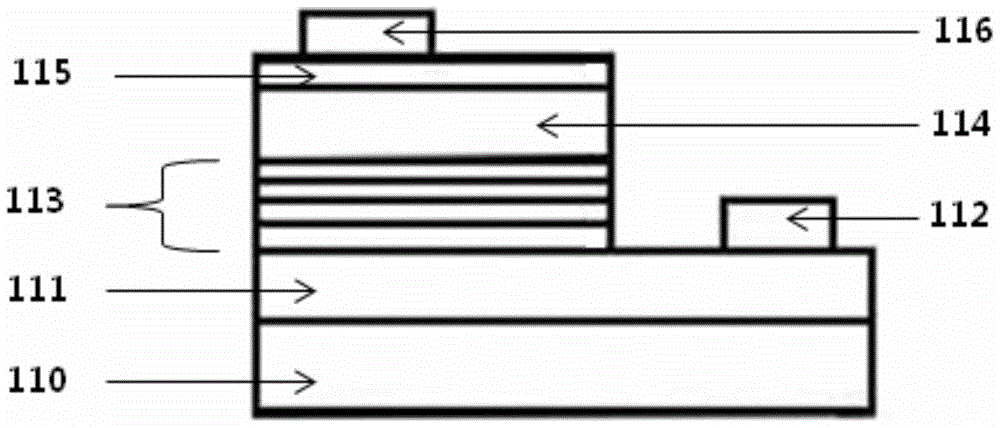

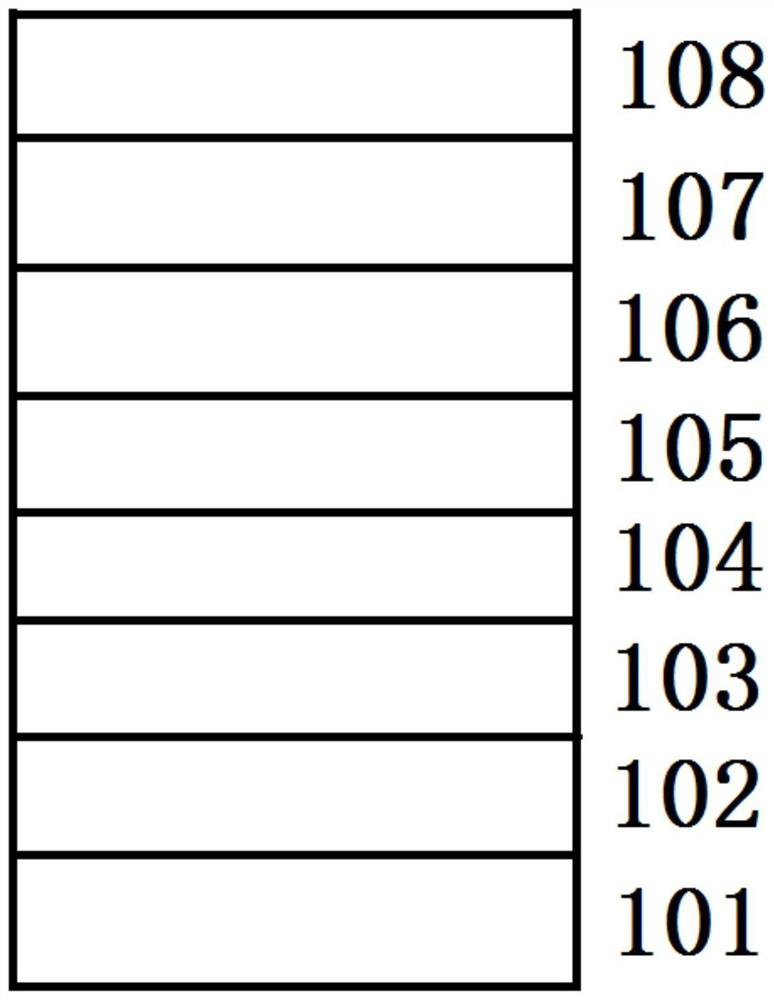

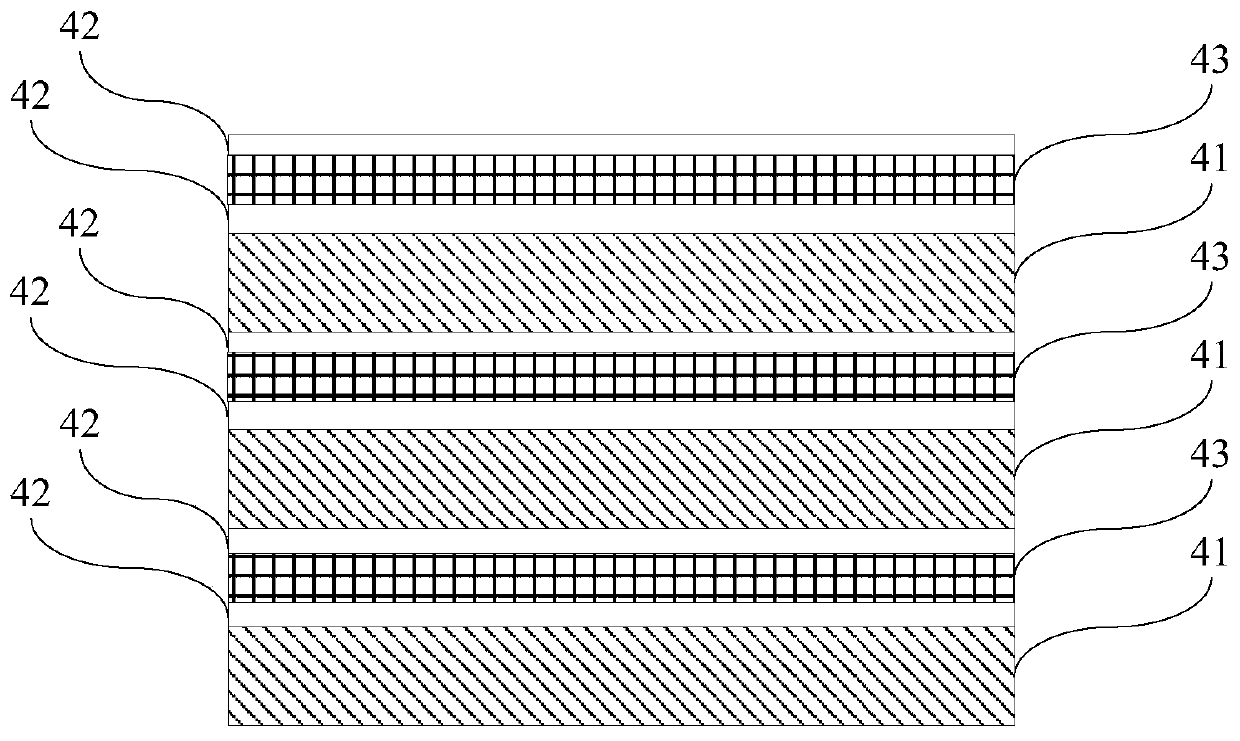

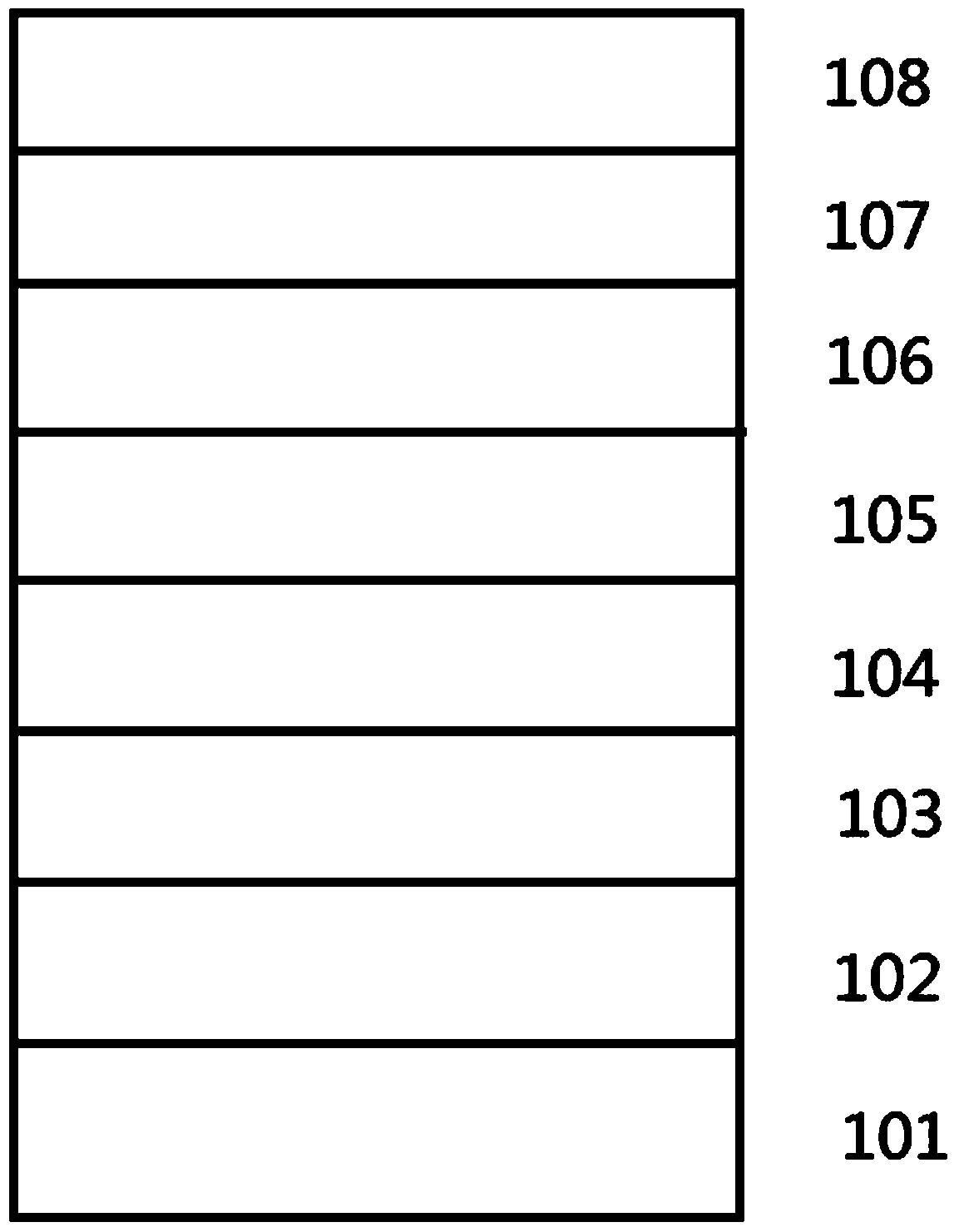

Light-emitting diode of photonic crystal structure and application thereof

ActiveCN102945902AImprove light extraction efficiencyReduced ohmic contact resistanceSemiconductor devicesCrystal structurePhotonic crystal structure

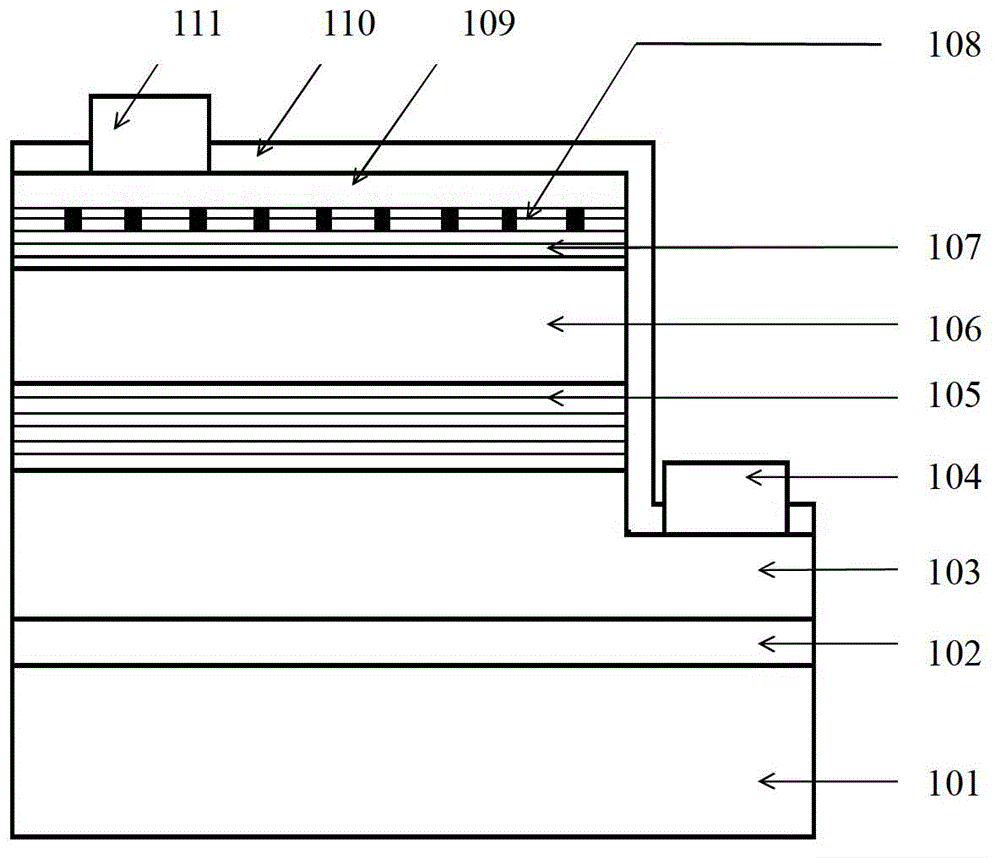

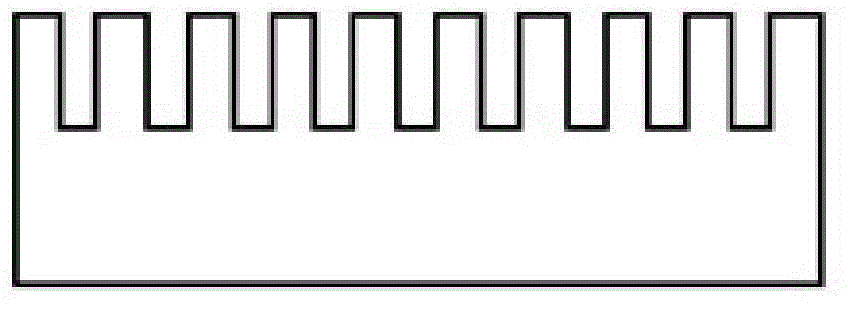

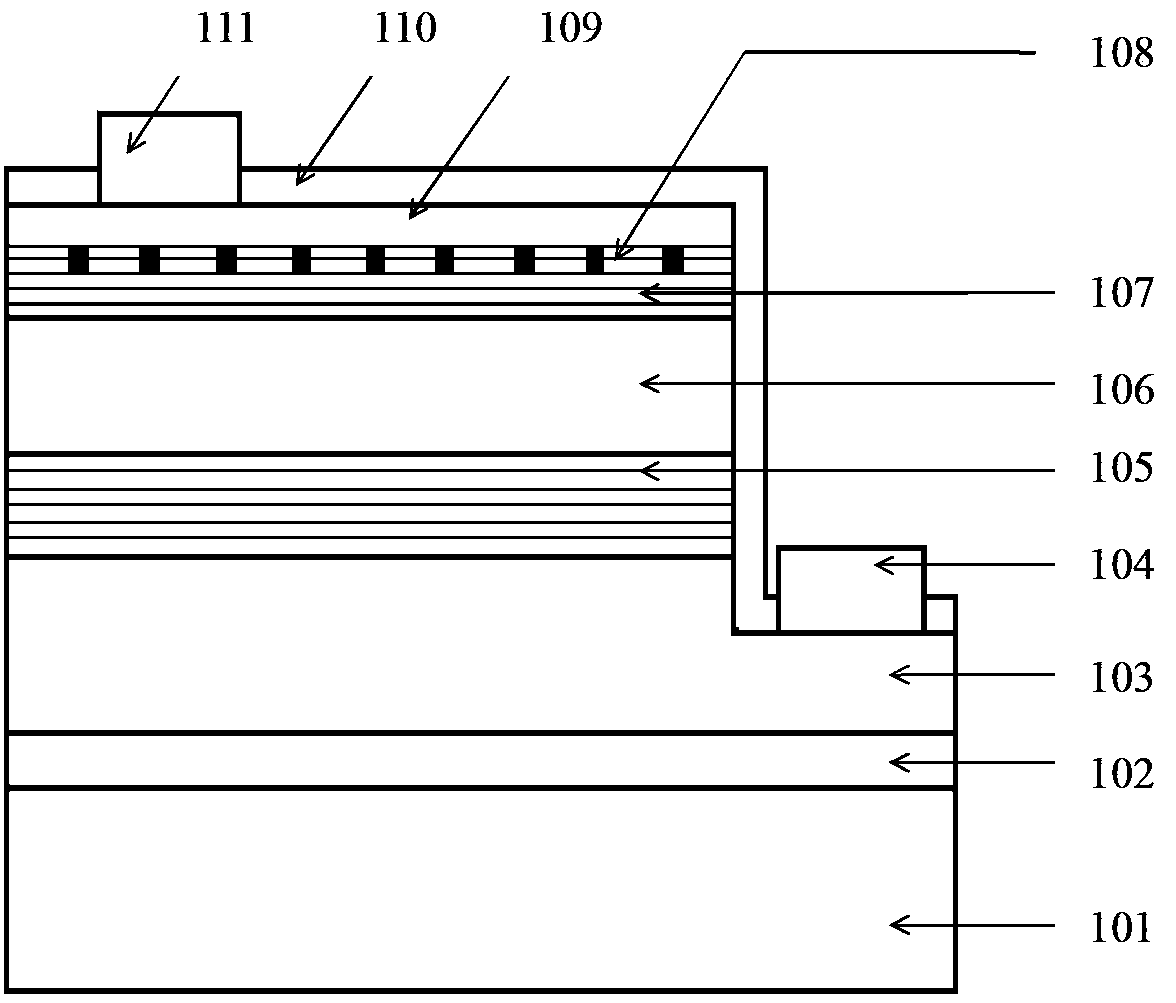

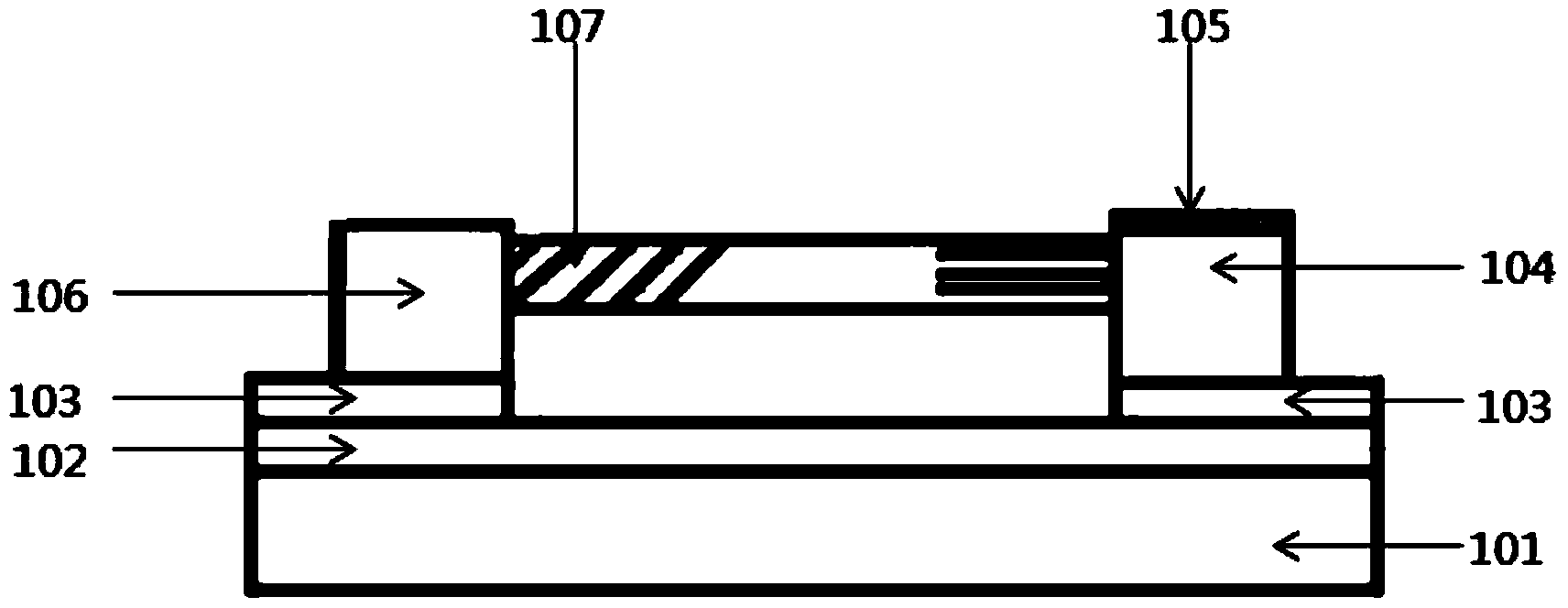

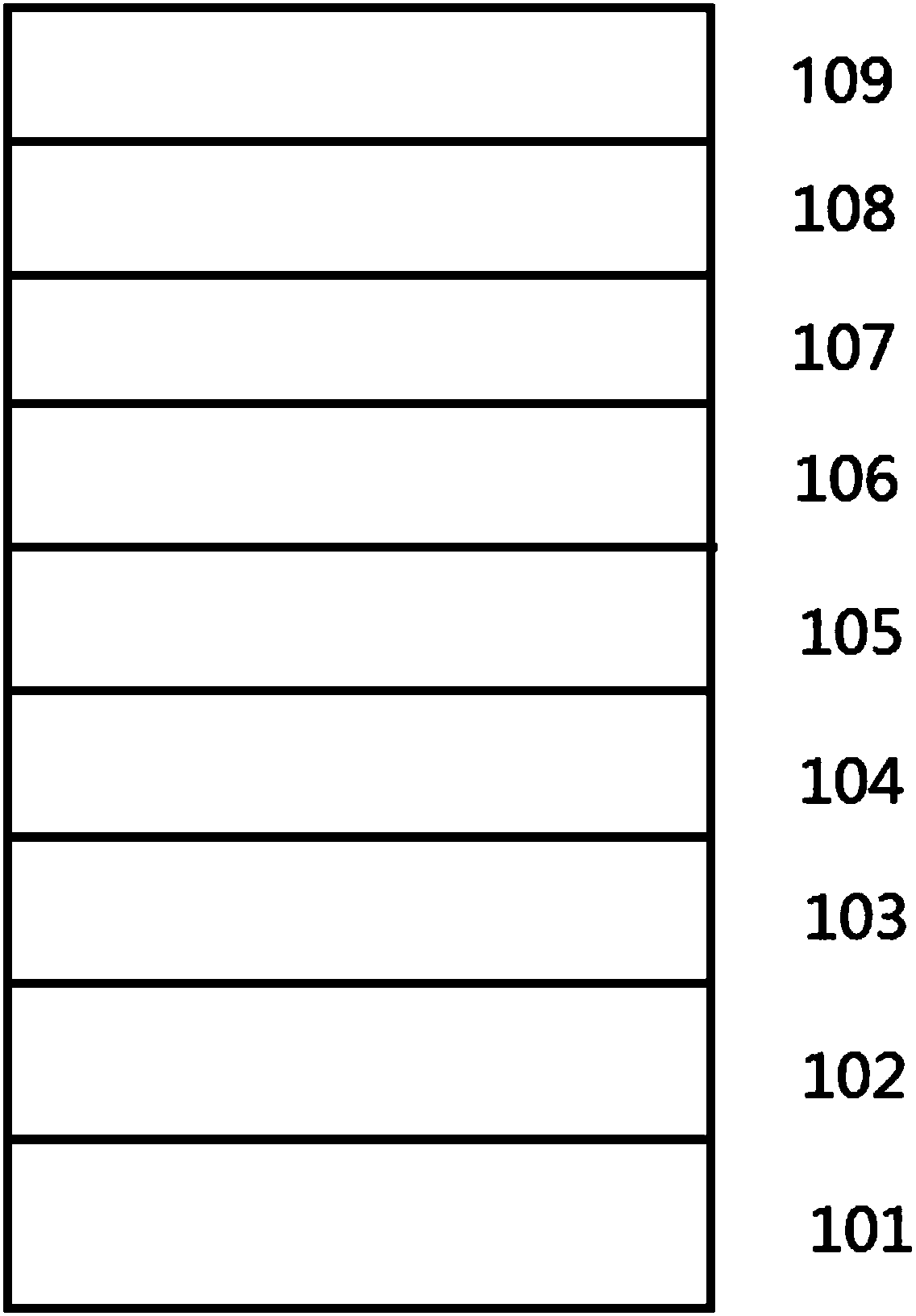

The invention provides a light-emitting diode of a photonic crystal structure. The light-emitting diode is provided with a substrate (101), a buffer layer (102), an n-type GaN epitaxial layer (103), an active luminescent layer (105) with InGaN / GaN multiple quantum wells, a p-type GaN epitaxial layer (106), a p-type super-lattice structure (107), a transparent conducting layer (109) and a passivation layer (110) in sequence from bottom to top, wherein an n-type electrode (104) is further arranged on the n-type GaN epitaxial layer (103); a p-type electrode (111) is further arranged on the transparent conducting layer (109); and a photonic crystal structure (108) is prepared in the p-type super-lattice structure (107). The light-emitting diode is applicable to a GaN-based LED (Light-emitting Diode), and is also applicable to other photo-electronic apparatuses which need to improve reflectivity of a certain wave band.

Owner:SOUTHEAST UNIV

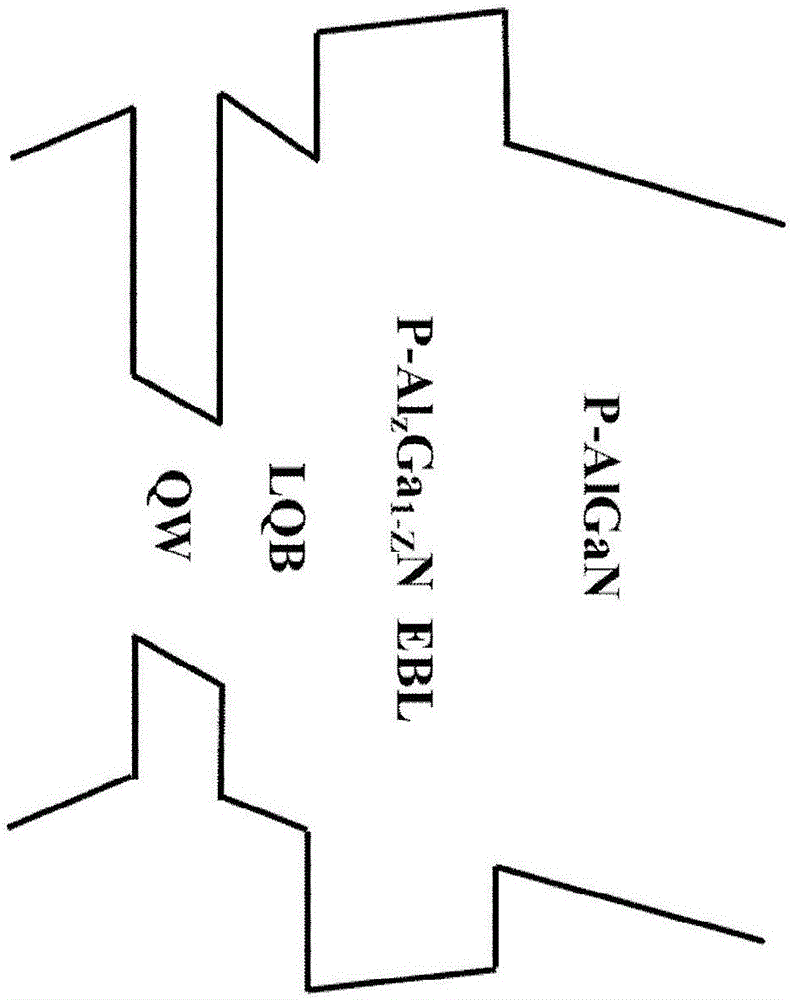

Method for preparing p-type AlGaN/AlInGaN electron blocking layer near ultraviolet LED with doping density and Al component in stepwise change

ActiveCN106299038AImprove injection efficiencyImprove composite luminous efficiencySemiconductor devicesUltravioletElectron blocking layer

The invention provides a method for preparing a p-type AlGaN / AlInGaN electron blocking layer near ultraviolet LED with doping density and Al component in stepwise change. In an LED epitaxial structure, an electron blocking layer adopts a p-type Aly1Ga1-y1N / AlyInx1Ga1-x1N superlattice structure, and the Al component is reduced from 0.2 to 0.05 stepwisely with the increase of superlattice cycle number; Mg doping density increases stepwisely with the increase of superlattice cycle number, and corresponding hole concentration increases from 0.5*10<17> cm<3> to 2* 10<17> cm<3>; the thickness range of the AlGaN barrier layer is 2-5 nm; and the thickness of the GaN well layer is 2 nm-5 nm. Through the design of the novel ultraviolet LED electronic blocking layer structure, hole injection efficiency can be improved effectively, and electron-hole recombination luminescence efficiency is improved, and thus near ultraviolet LED luminescence efficiency is improved.

Owner:东莞市中晶半导体科技有限公司

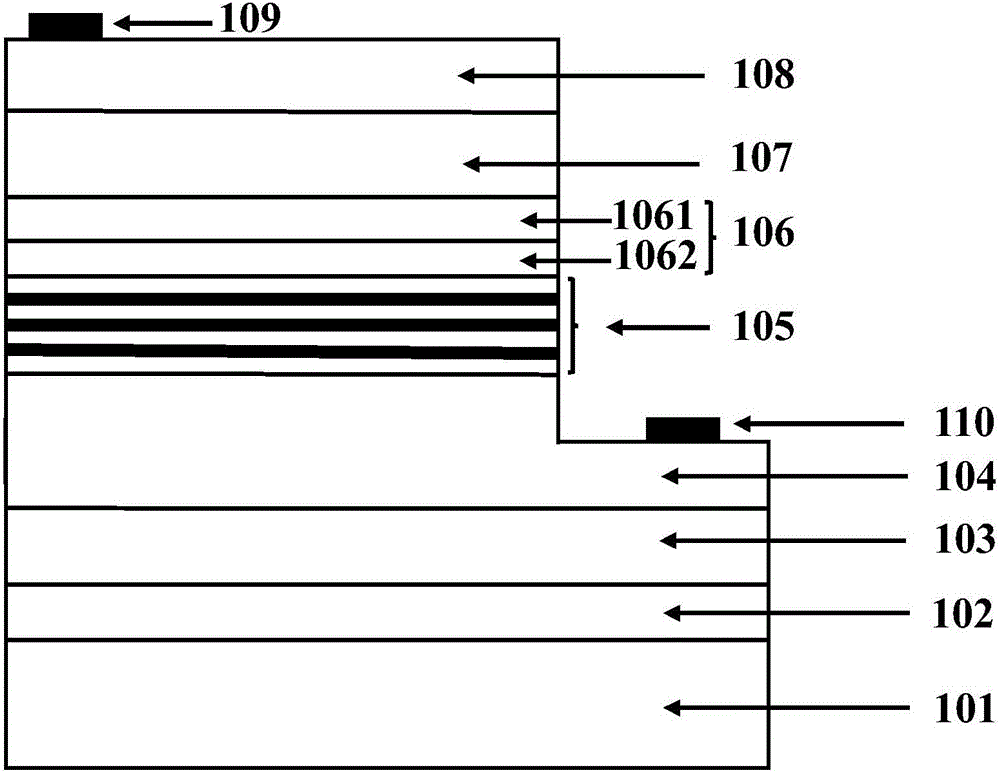

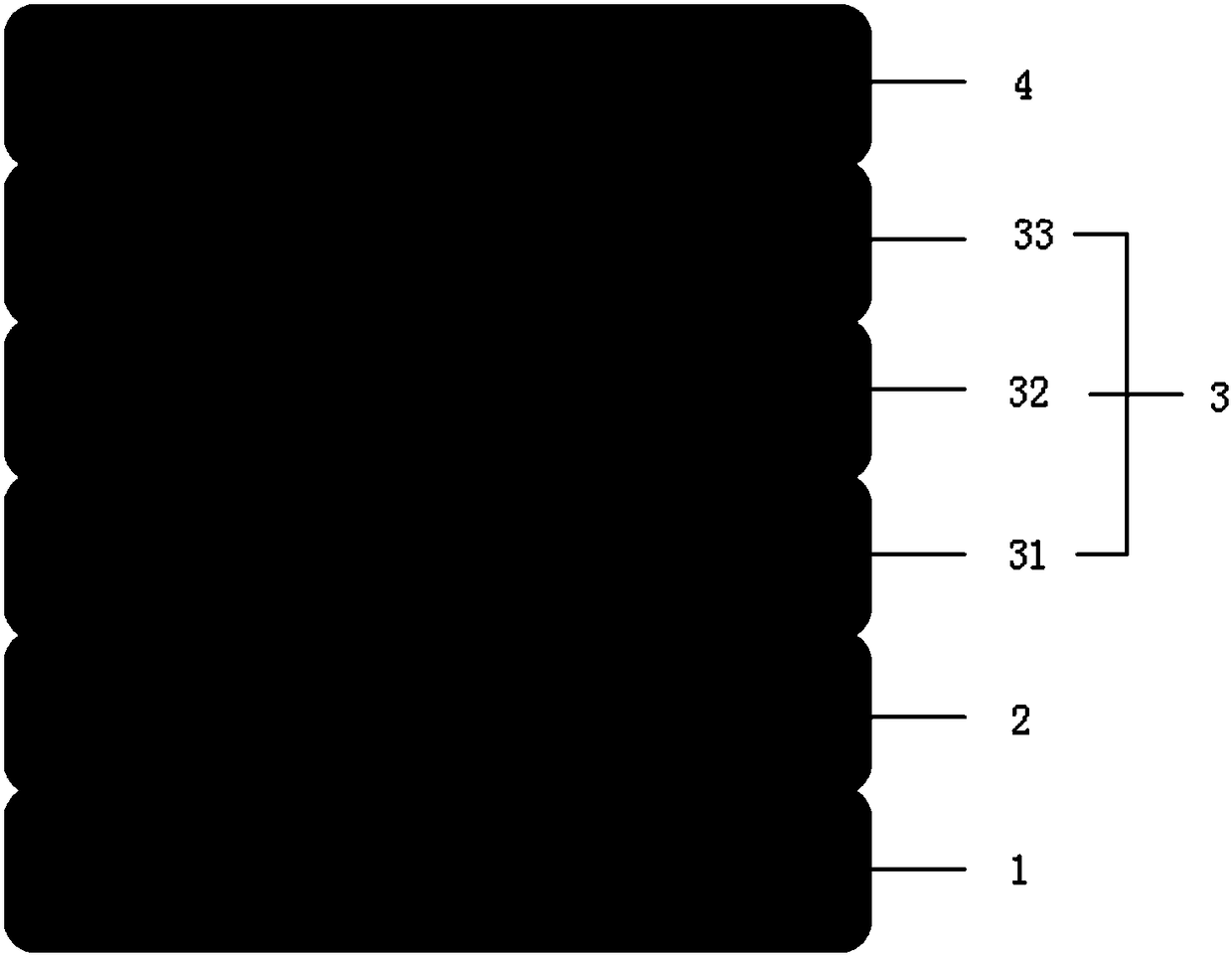

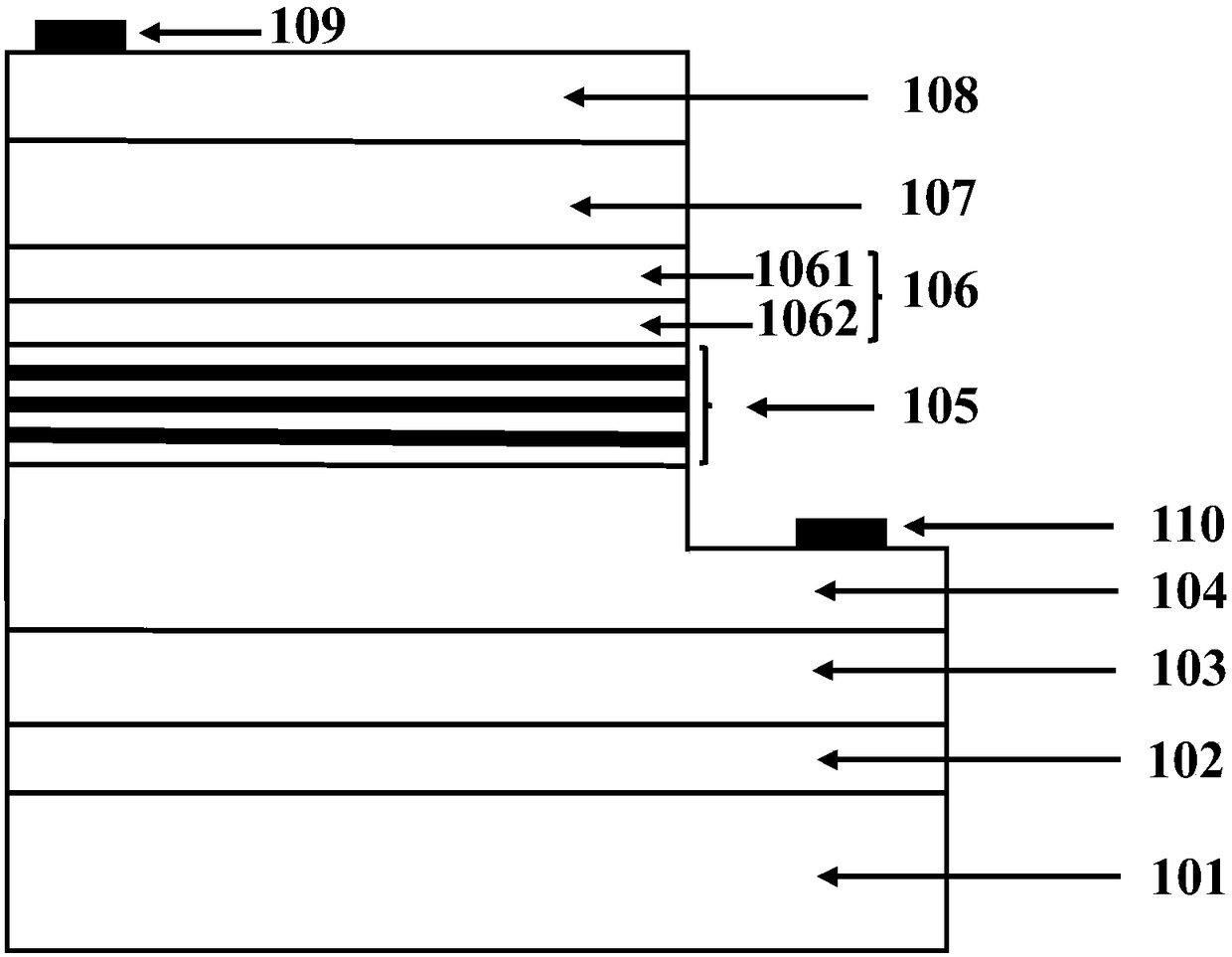

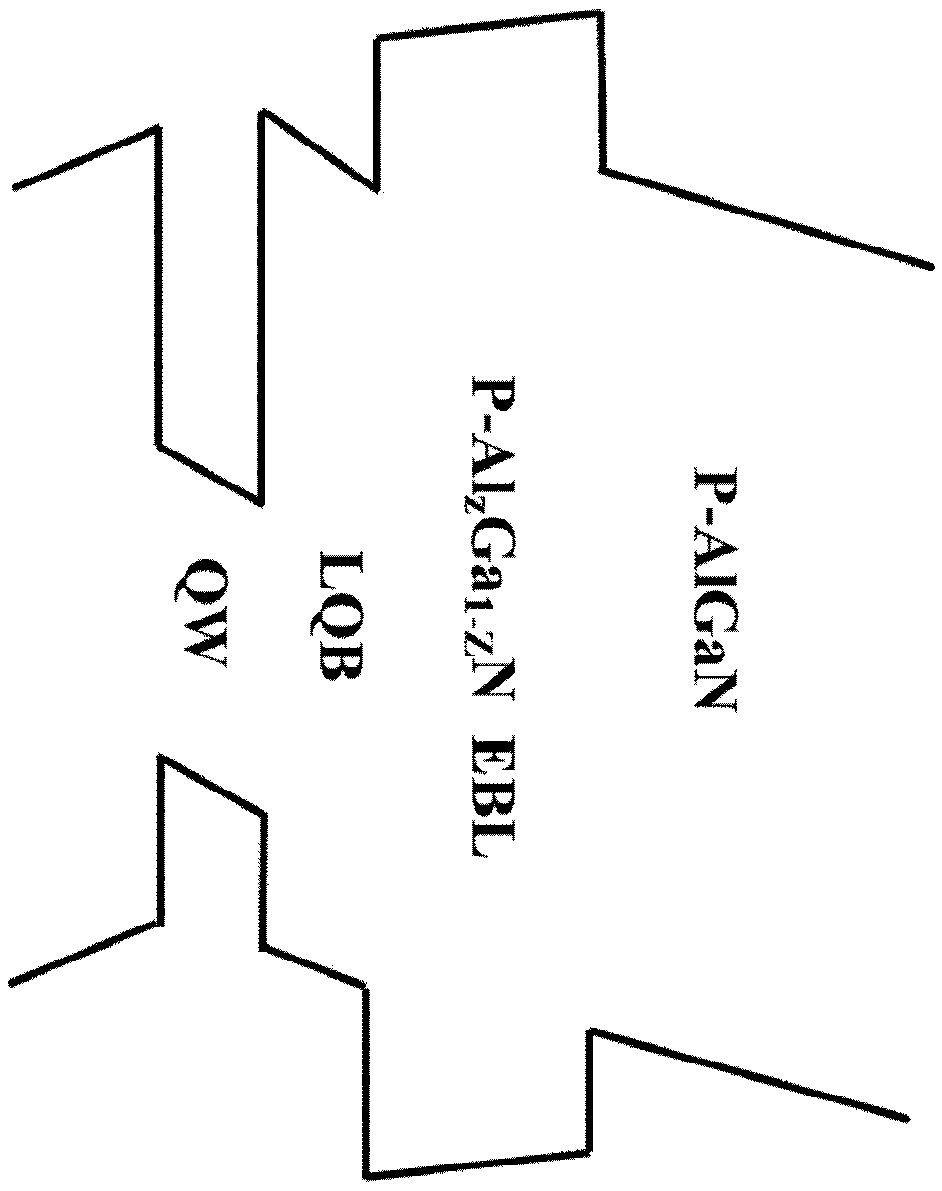

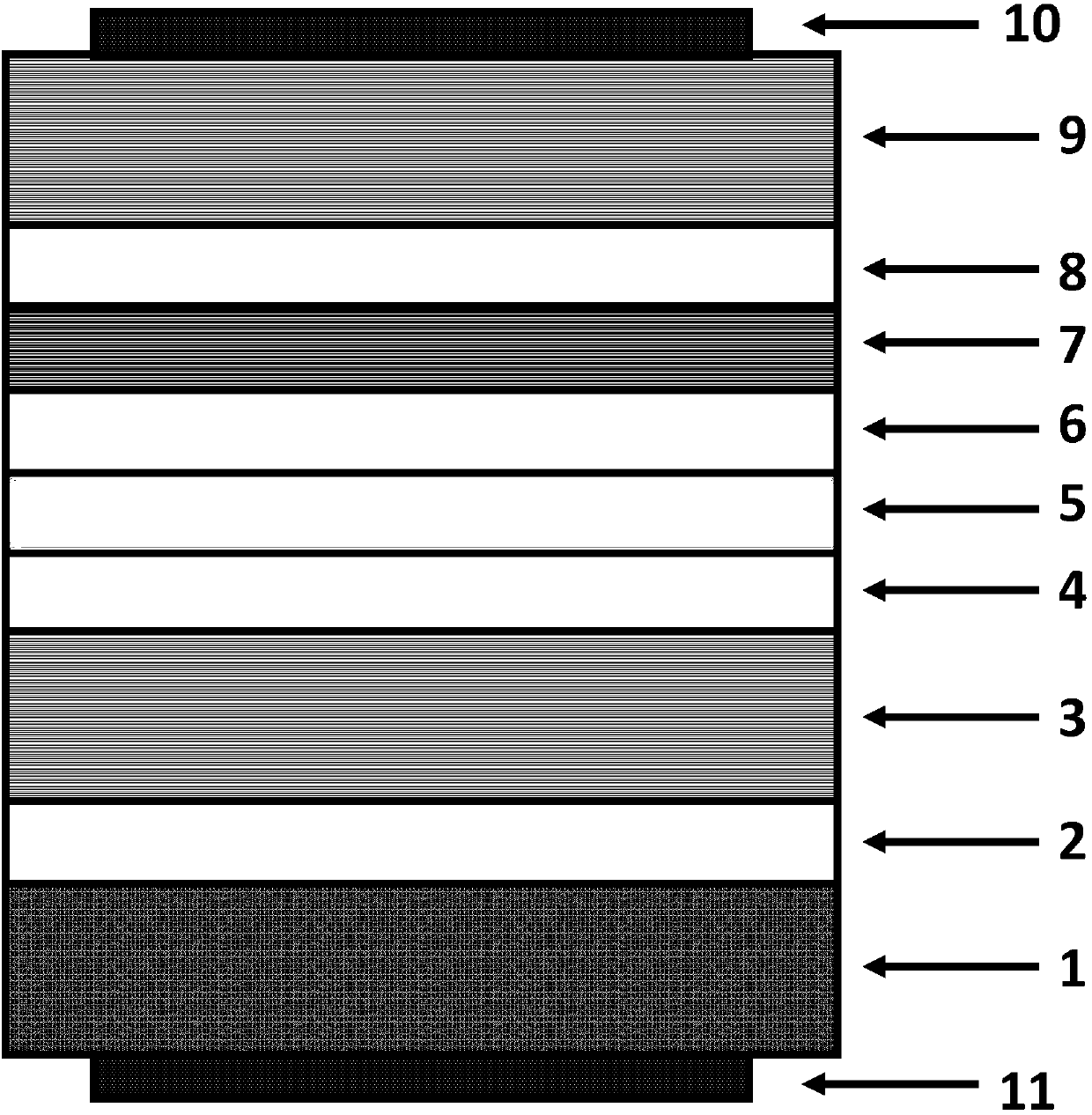

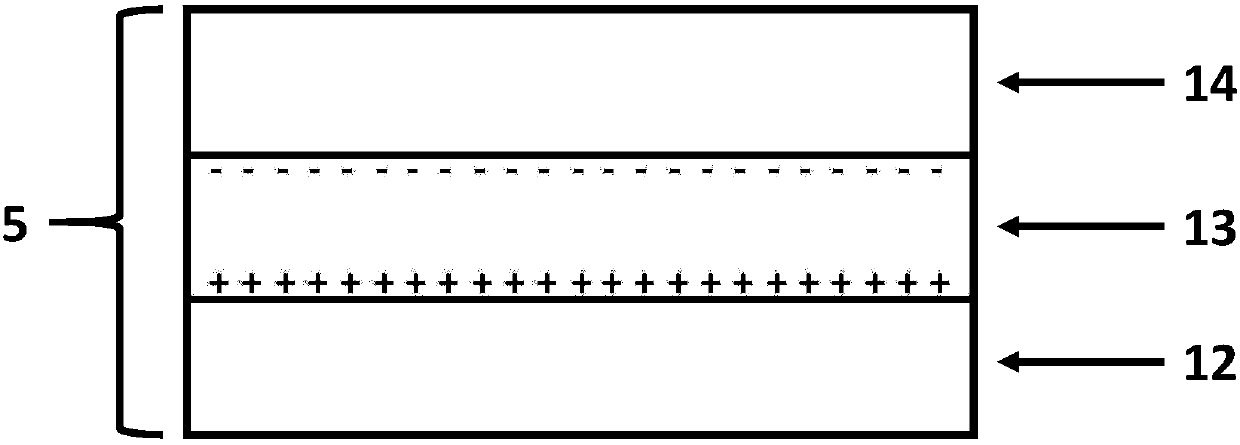

UV light emitting diode with compound electronic barrier layer structure

ActiveCN105977356APrevent overflowImprove composite luminous efficiencySemiconductor devicesQuantum wellNucleation

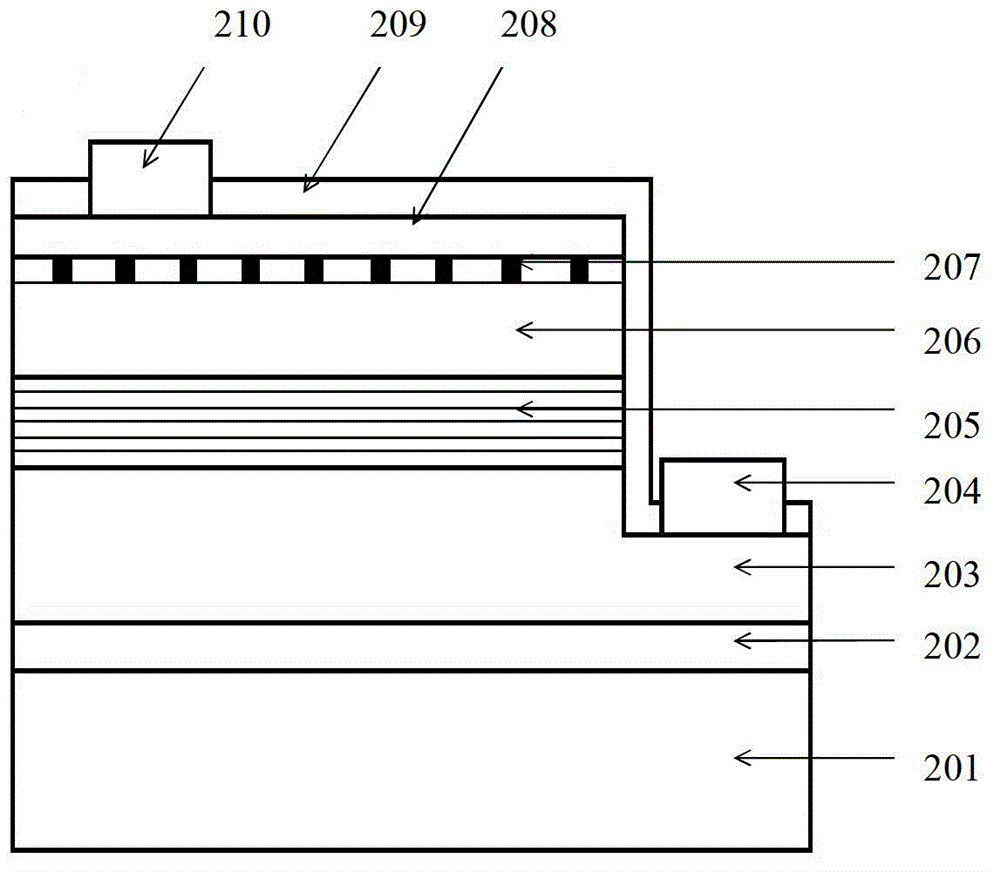

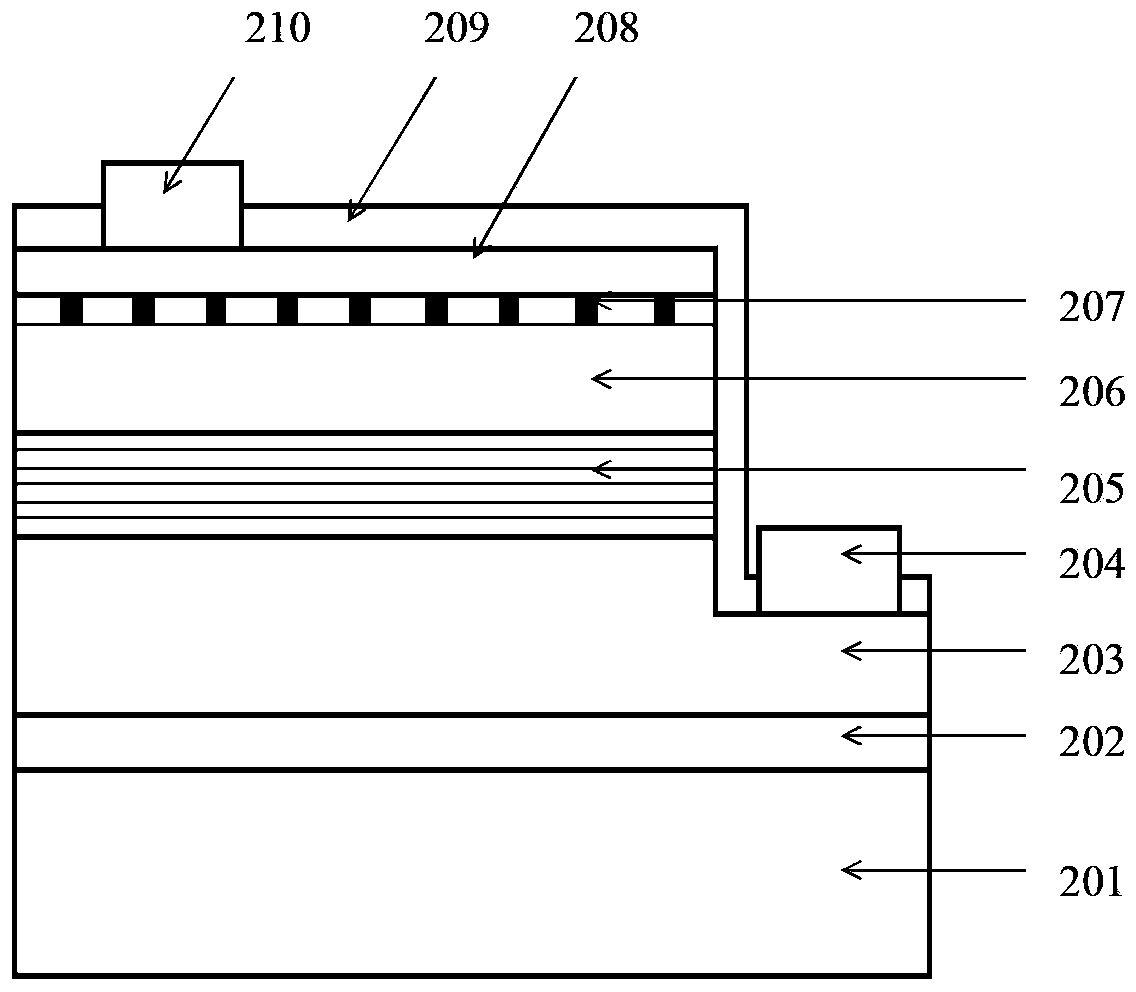

The invention discloses a UV light emitting diode with a compound electronic barrier layer structure. The light emitting diode, successively from the bottom to the top, includes a substrate (101), a low-temperature AlN nucleation layer (102), a high-temperature AlN buffer layer (103), an n type AlGaN layer (104), an Al<x>Ga<1-x>N / Al<y>Ga<1-y>N multi-quantum well active region (105), and a p-AlsIntGa1-s-tN / p-AlzGa1-zN compound electronic barrier layer (106) consisting of a p-Al<s>In<t>Ga<1-s-t> layer (106) and a p-Al<z>Ga<1-z>N layer. The diode provided can solve the problem that a conventional electronic barrier layer structure generates a parasitic electronic inversion layer between the last quantum well barrier and an electronic barrier layer.

Owner:SOUTHEAST UNIV

GaN-based LED structure and formation method thereof

InactiveCN105304779ASimple structureRaise the barrier heightSemiconductor devicesElectron holeQuantum well

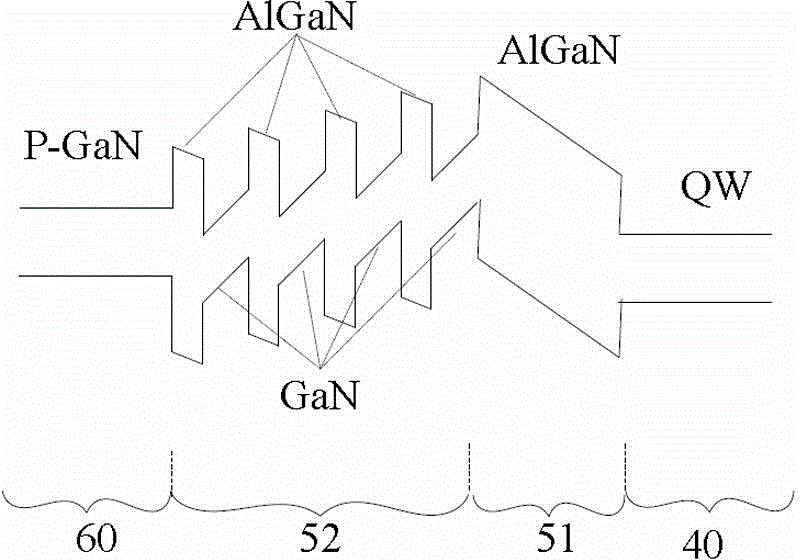

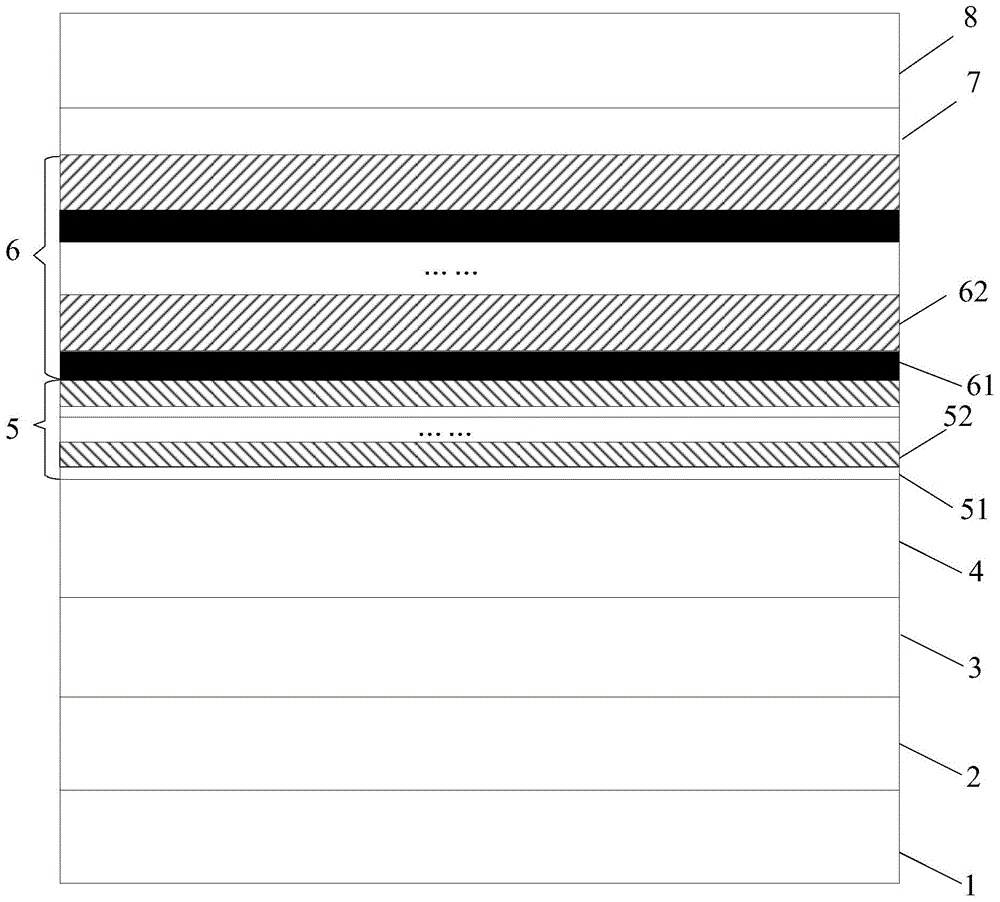

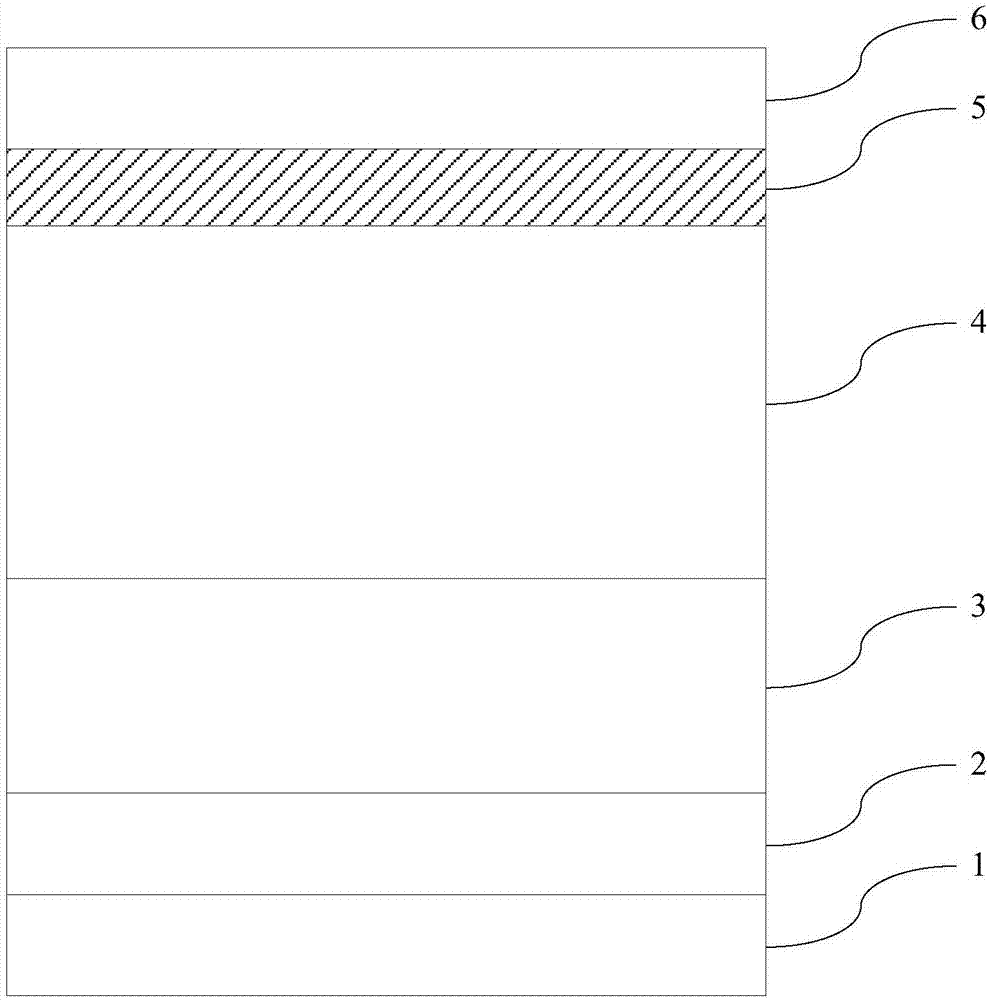

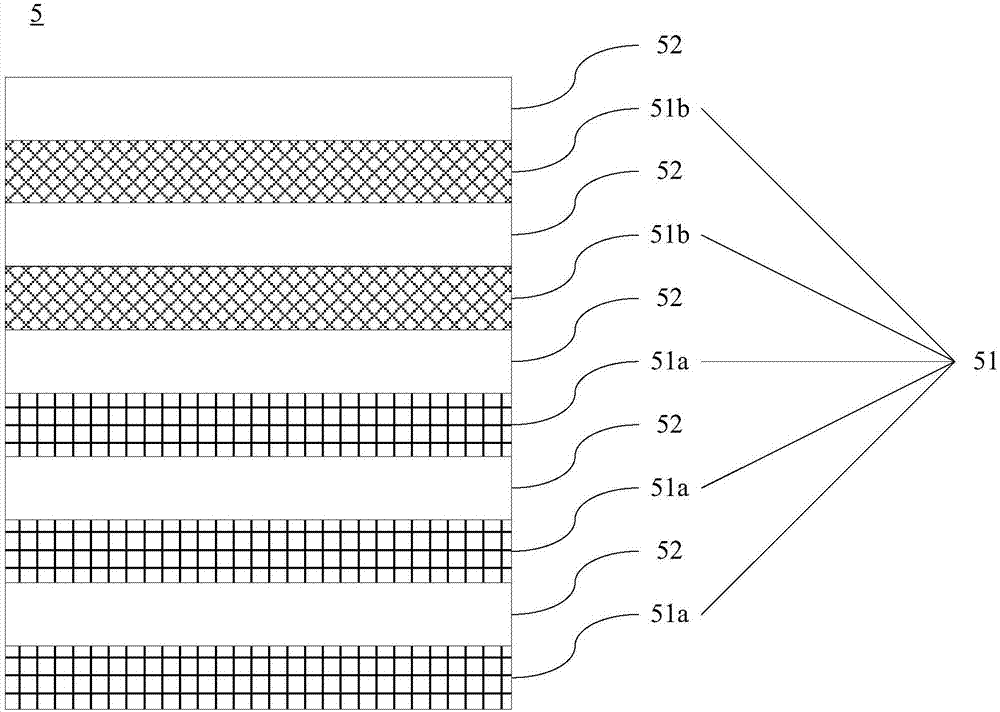

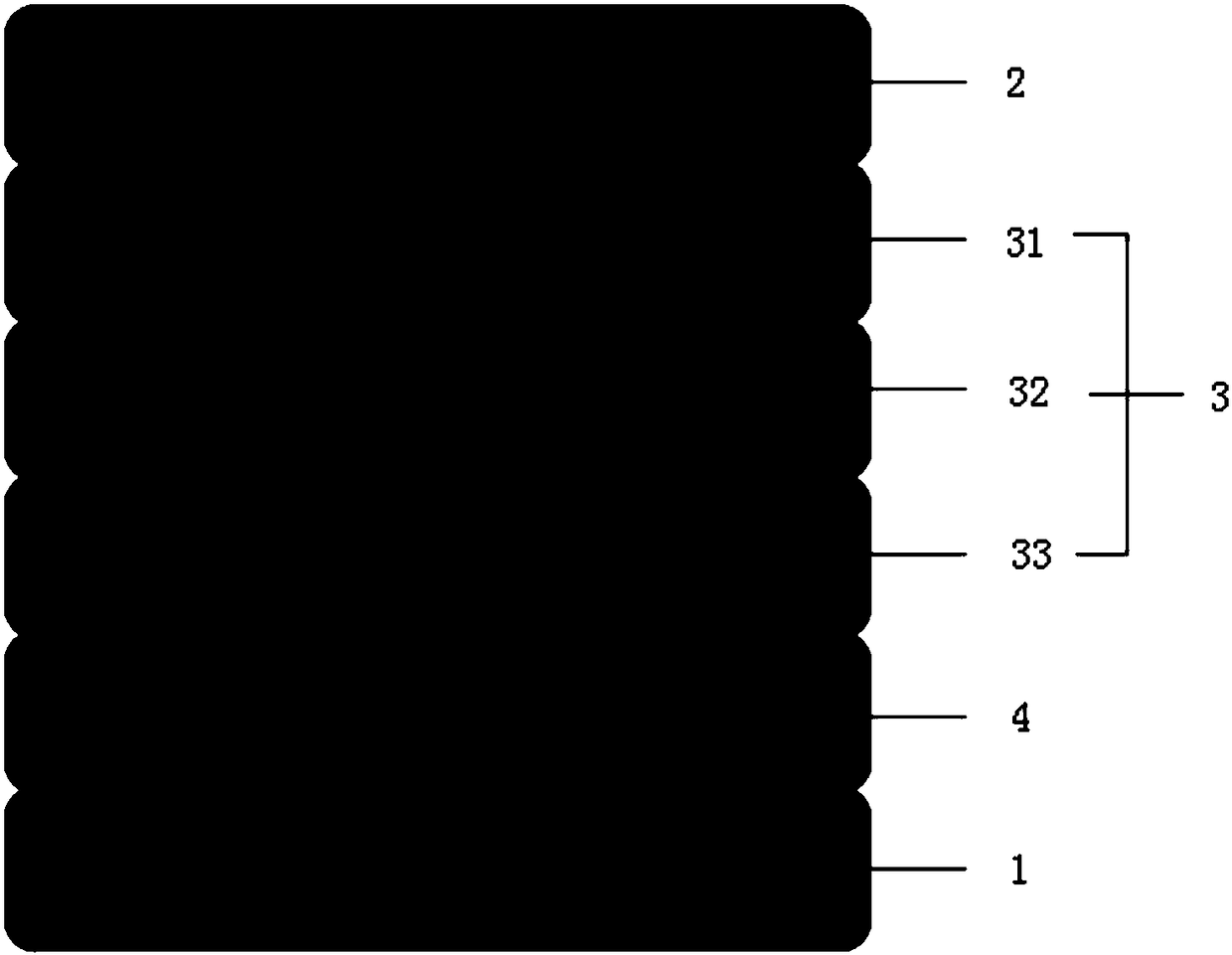

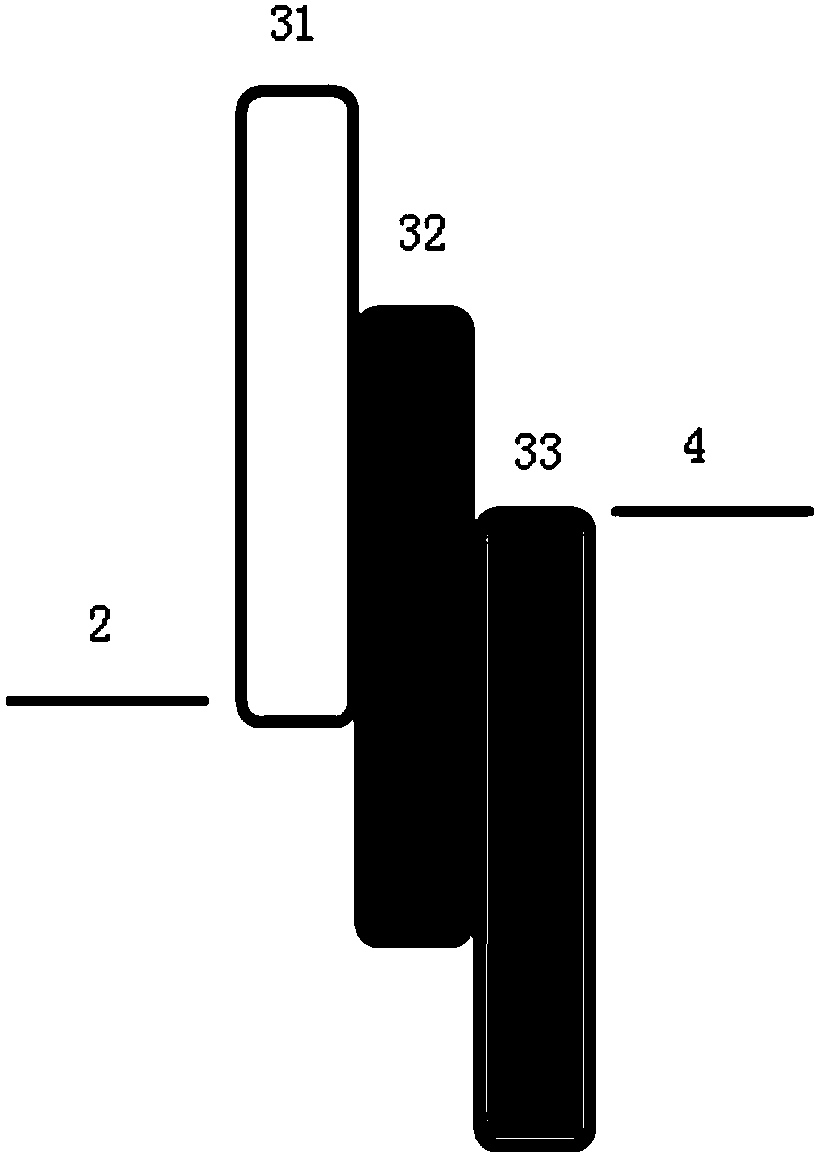

The invention discloses a GaN-based LED structure and a formation method thereof. The GaN-based LED structure comprises a substrate; a GaN buffer layer formed on the substrate; a first-doping-type GaN layer arranged on the GaN buffer layer; a quantum well luminous layer arranged on the first-doping-type GaN layer; a second-doping-type GaN layer arranged on the quantum well luminous layer; an electronic barrier layer arranged between the quantum well luminous layer and a P-doping-type GaN layer, wherein the electronic barrier layer comprises a block structure layer and a superlattice structure layer, the forbidden band width of the block structure layer being larger than that of the GaN, and the superlattice structure layer is used for adjusting the energy band inclination degree between the P-doping-type GaN layer and the block structure layer so as to reduce hole barrier height; and a P electrode and an N electrode. The GaN-based LED structure adopts a composite structure of the block structure layer and the superlattice structure layer, so that composite luminescence efficiency of electron holes in the quantum well luminous layer is greatly improved; and the GaN-based LED structure has the advantage of simple structure and the like.

Owner:HUIZHOU BYD IND

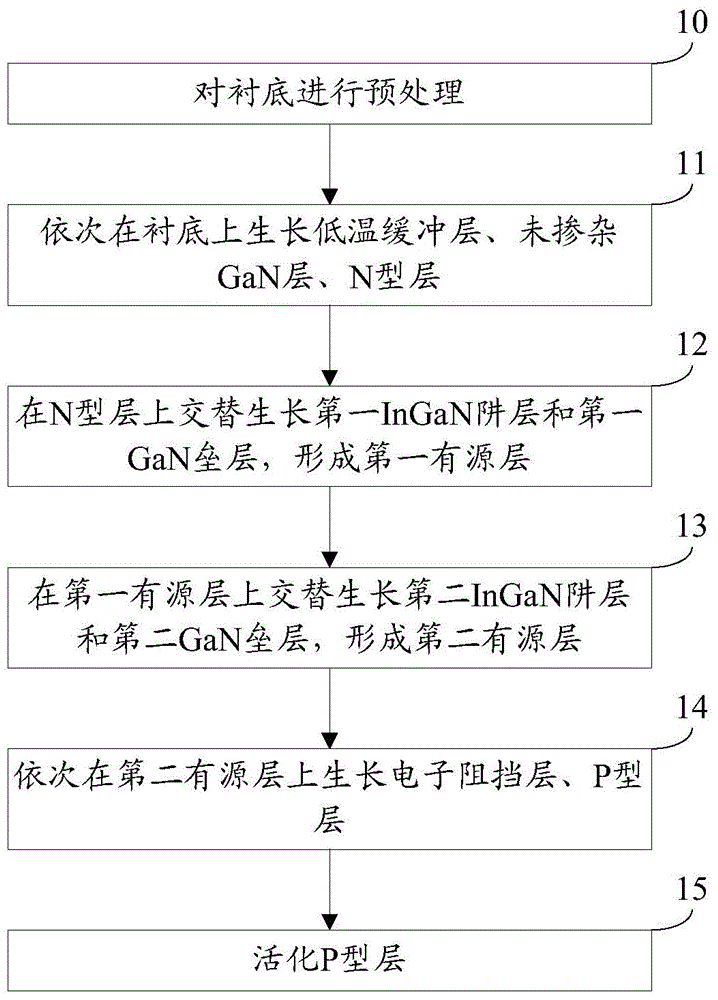

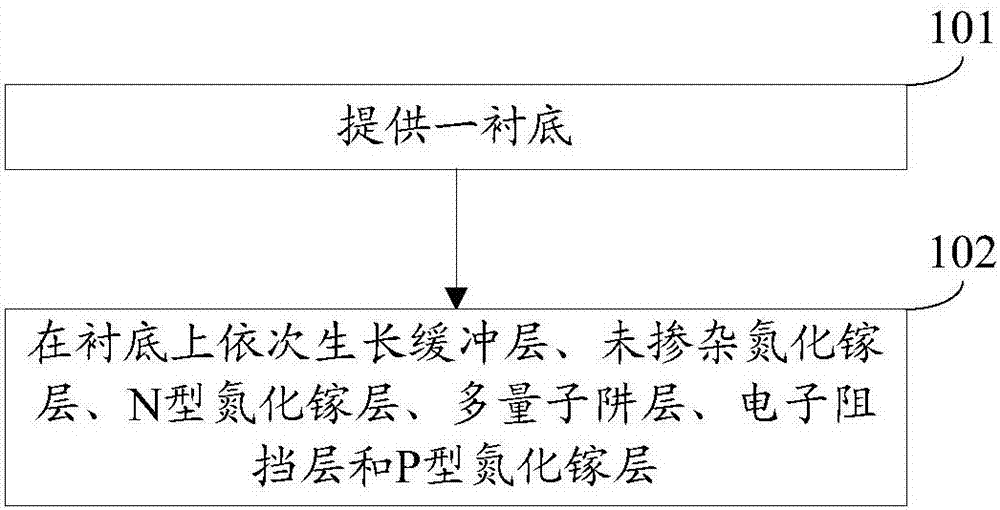

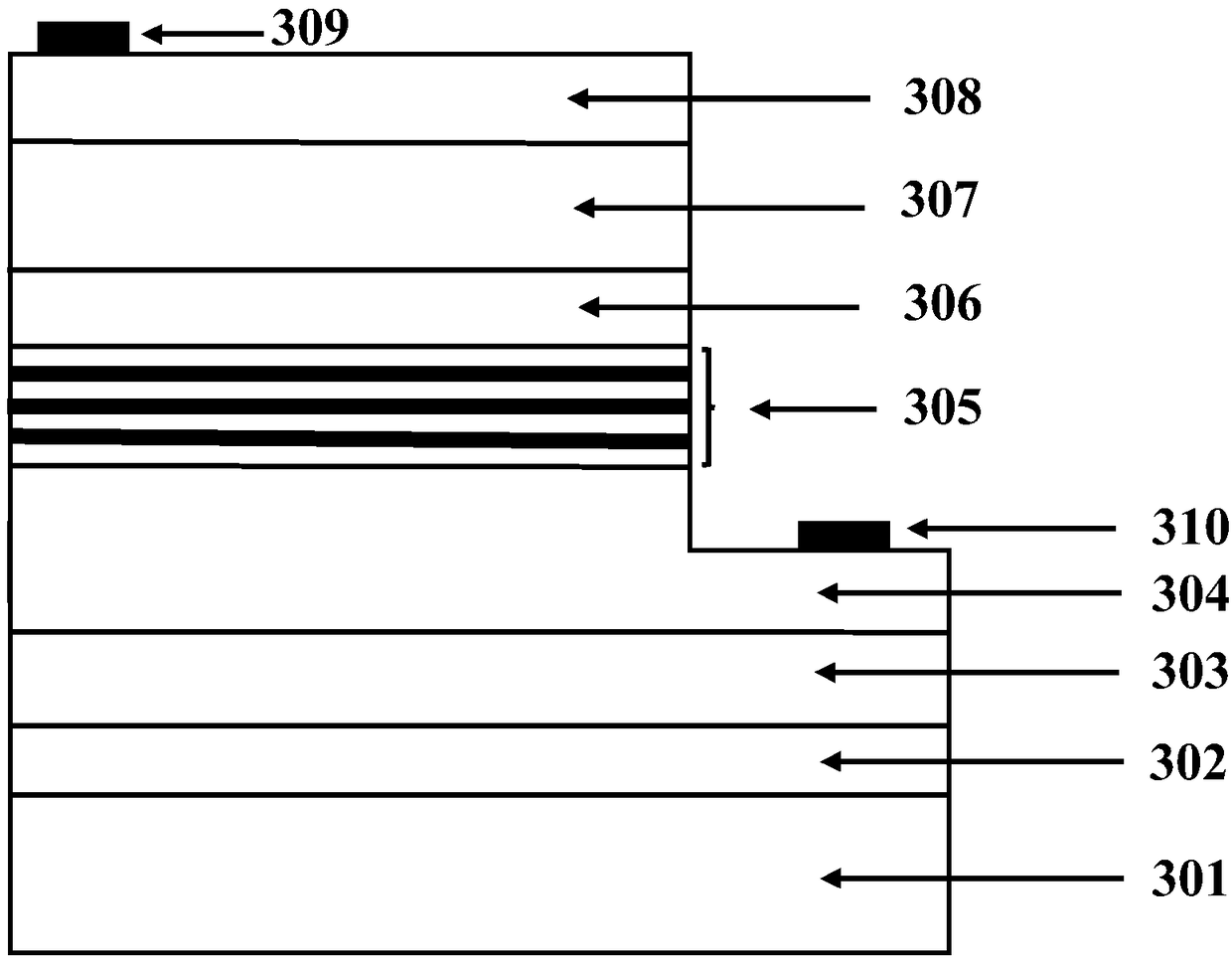

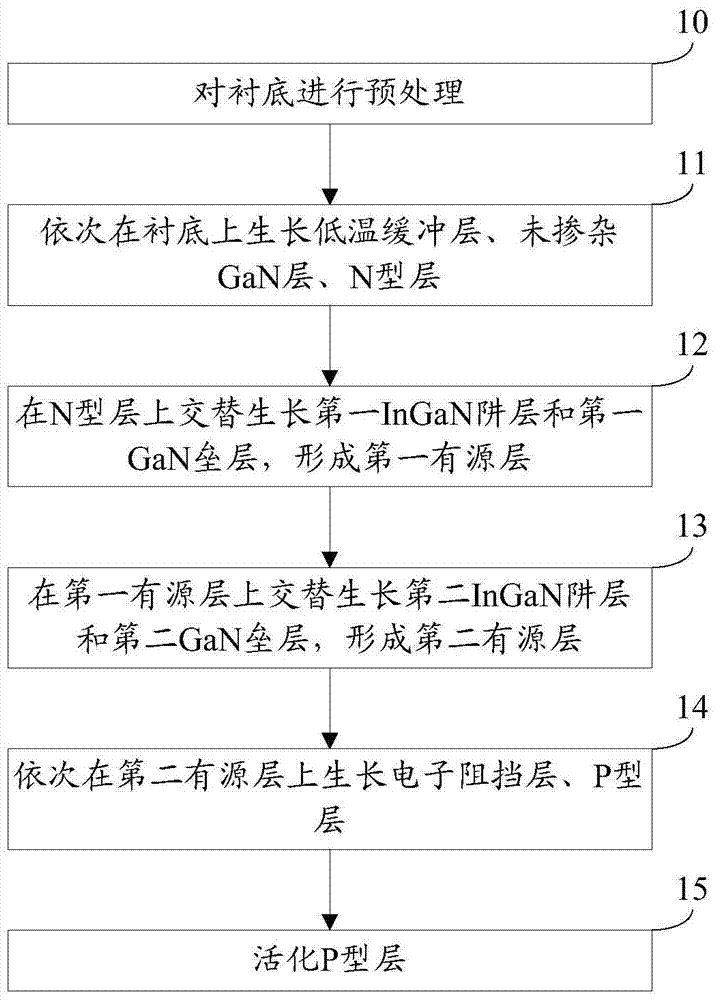

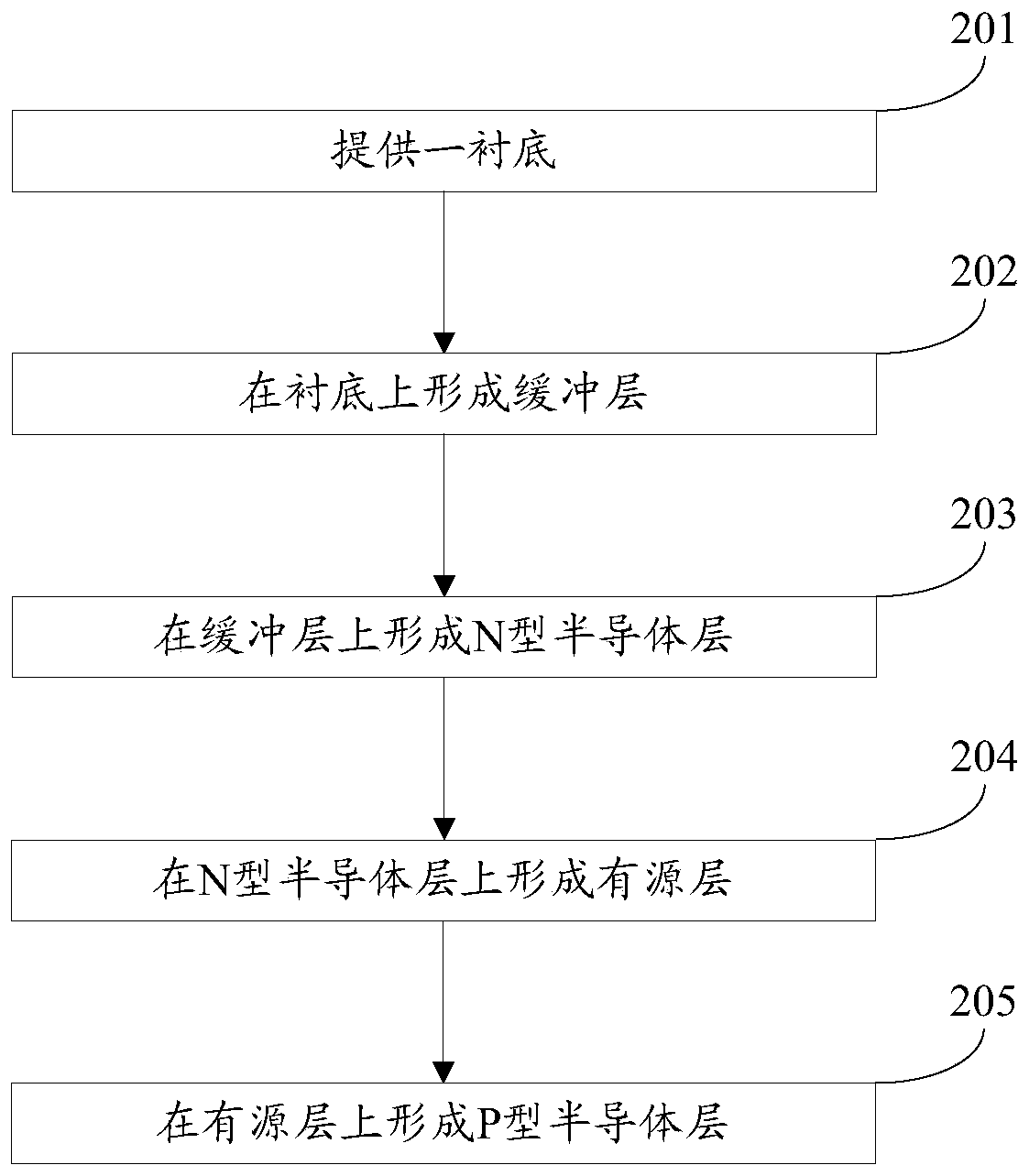

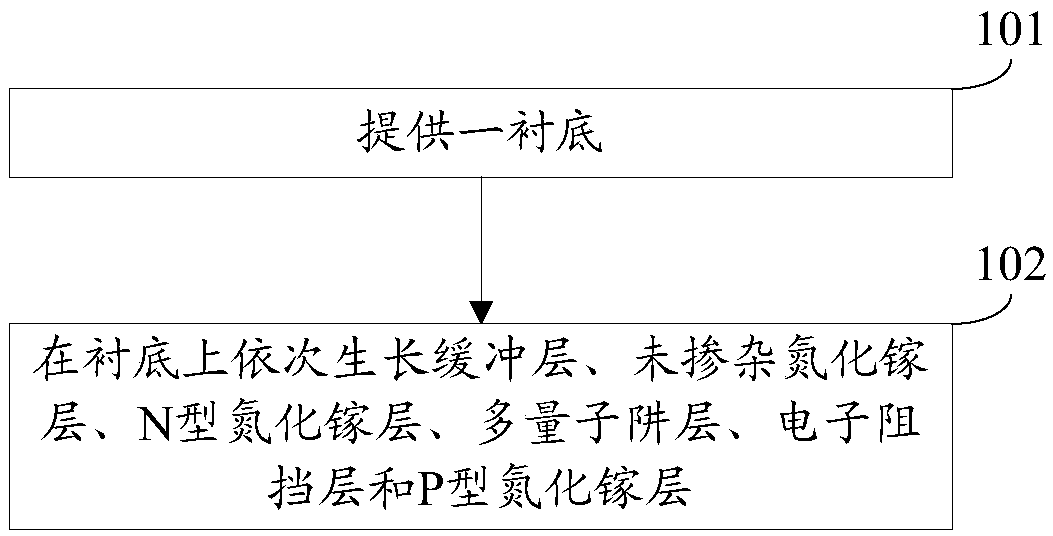

Growth method for light-emitting diode epitaxial wafer and epitaxial wafer

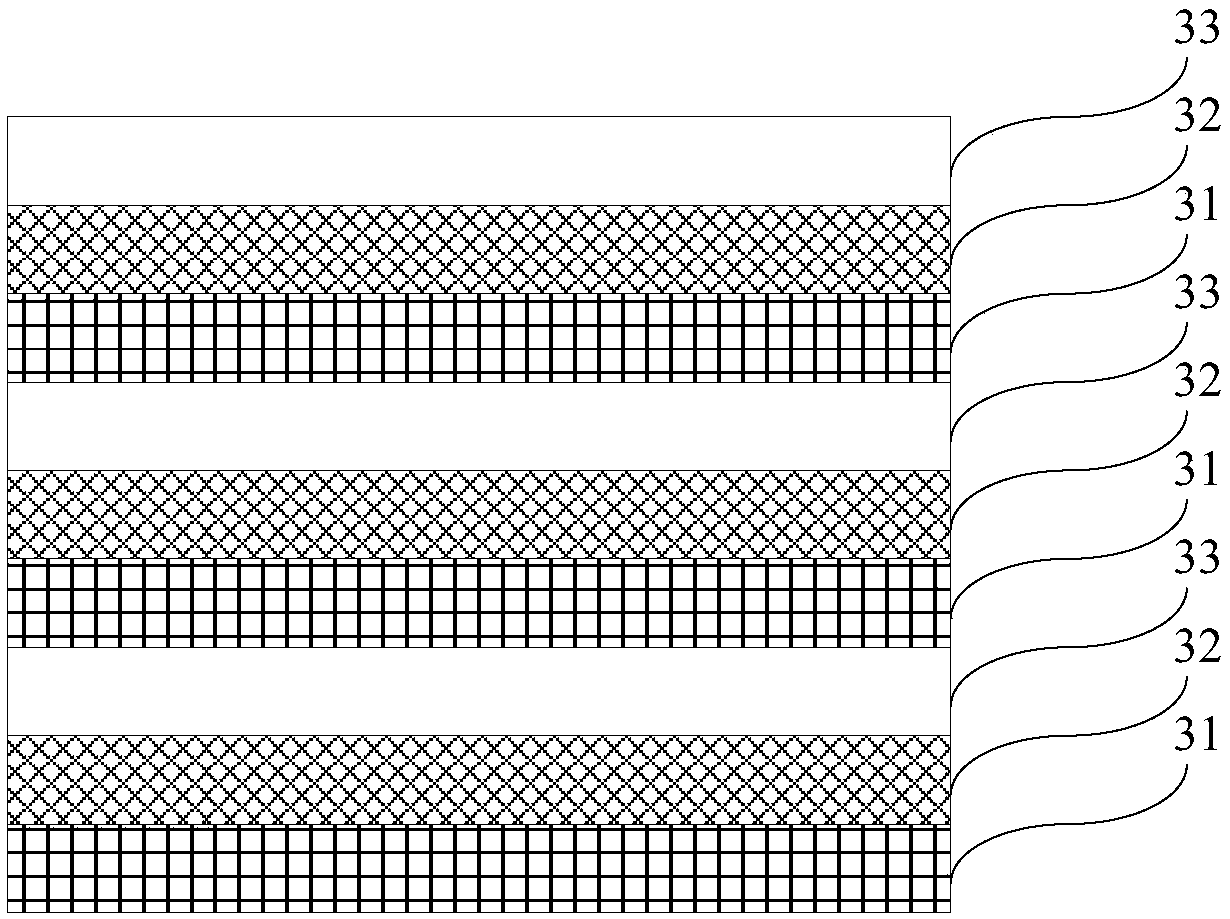

The invention discloses a growth method for a light-emitting diode epitaxial wafer and an epitaxial wafer, belonging to the technical field of a semiconductor. The growth method comprises the following steps of: sequentially growing a low-temperature buffer layer, a non-doped GaN layer and an N-type layer on a substrate; alternatively growing a first InGaN pit layer and a first GaN barrier layer on the N-type layer to form a first active layer; alternatively growing a second InGaN pit layer and a second GaN barrier layer on the first active layer to form a second active layer; and sequentially growing an electron blocking layer and a P-type layer on the second active layer, wherein the growth pressure of the second active layer is lower than the growth pressure of the first active layer, the growth speed of the second active layer is lower than the growth speed of the first active layer, the thickness of the second active layer is smaller than the thickness of the first active layer, and the growth pressure, the growth speed and the thickness of the second InGaN pit layer are gradually reduced, slowed and decreased along the growth direction of the light-emitting diode epitaxial wafer. The epitaxial wafer is high in luminous efficiency.

Owner:HC SEMITEK SUZHOU

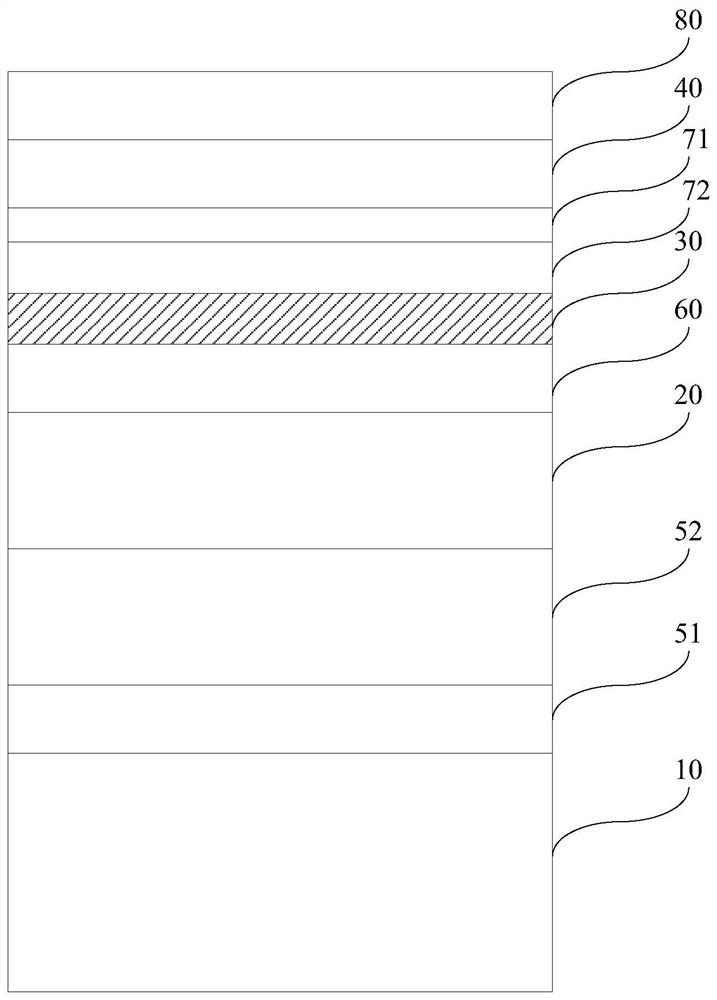

Light-emitting diode epitaxial wafer and fabrication method thereof

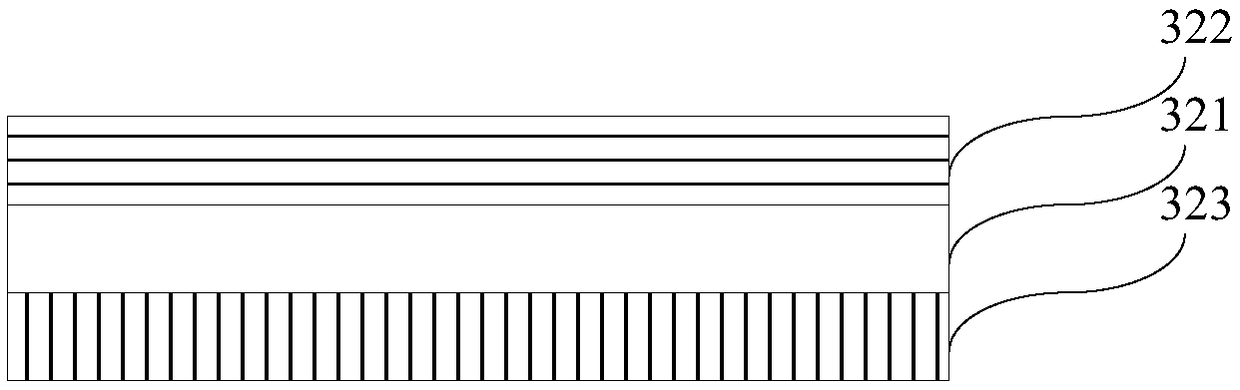

ActiveCN109346576AReduce heterojunction mismatchImprove crystal qualitySemiconductor devicesLight-emitting diodeTransition layer

The invention discloses a light-emitting diode epitaxial wafer and a fabrication method thereof, and belongs to the technical field of semiconductors. The light-emitting diode epitaxial wafer comprises a substrate, an N-type semiconductor layer, an active layer and a P-type semiconductor layer, wherein the N-type semiconductor layer, the active layer and the P-type semiconductor layer are sequentially laminated on the substrate, the active layer comprises a plurality of composite structures which are sequentially laminated, each composite structure comprises a well layer and a barrier layer which are sequentially laminated, the material of the well layer employs non-doped InGaN, the material of the barrier layer employs non-doped GaN, the composite structure also comprises a transition layer, the transition layer is arranged between the well layer and the barrier layer, the transition layer comprises a first sub-layer and a second sub-layer which are sequentially laminated, the material of the first sub-layer employs non-doped AlInN, and the material of the second sub-layer employs non-doped AIN. By the light-emitting diode epitaxial wafer, the photoelectric performance of an LED can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Light-emitting diode of photonic crystal structure and application thereof

ActiveCN102945902BImprove light extraction efficiencyReduced ohmic contact resistanceSemiconductor devicesPhotonic crystal structureCrystal structure

The invention provides a light-emitting diode of a photonic crystal structure. The light-emitting diode is provided with a substrate (101), a buffer layer (102), an n-type GaN epitaxial layer (103), an active luminescent layer (105) with InGaN / GaN multiple quantum wells, a p-type GaN epitaxial layer (106), a p-type super-lattice structure (107), a transparent conducting layer (109) and a passivation layer (110) in sequence from bottom to top, wherein an n-type electrode (104) is further arranged on the n-type GaN epitaxial layer (103); a p-type electrode (111) is further arranged on the transparent conducting layer (109); and a photonic crystal structure (108) is prepared in the p-type super-lattice structure (107). The light-emitting diode is applicable to a GaN-based LED (Light-emitting Diode), and is also applicable to other photo-electronic apparatuses which need to improve reflectivity of a certain wave band.

Owner:SOUTHEAST UNIV

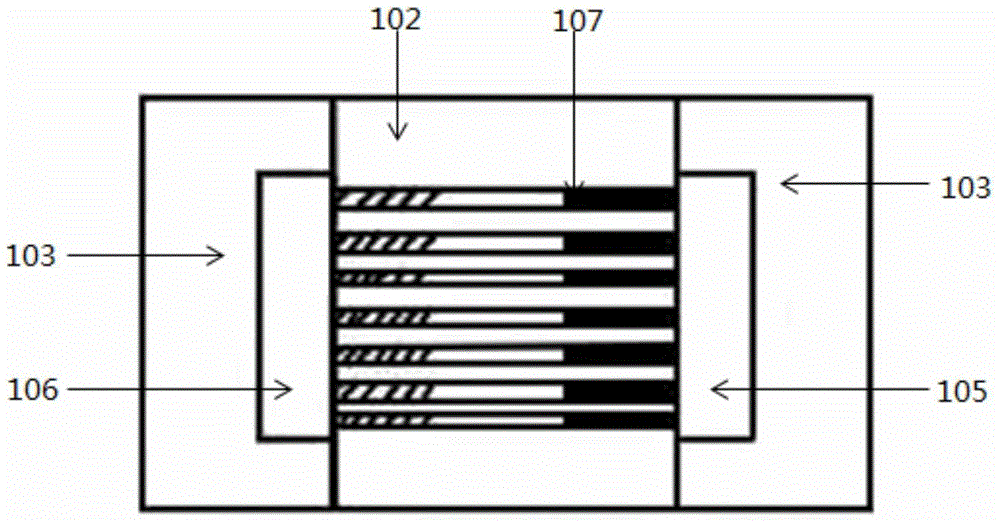

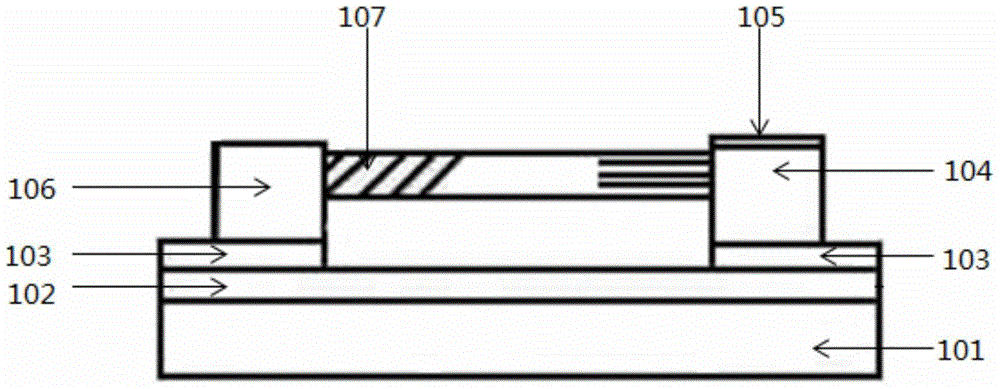

Transverse zinc oxide nanorod array light emitting diode

ActiveCN104051589AHigh light transmittanceImprove optical output powerMaterial nanotechnologySemiconductor devicesElectron injectionEtching

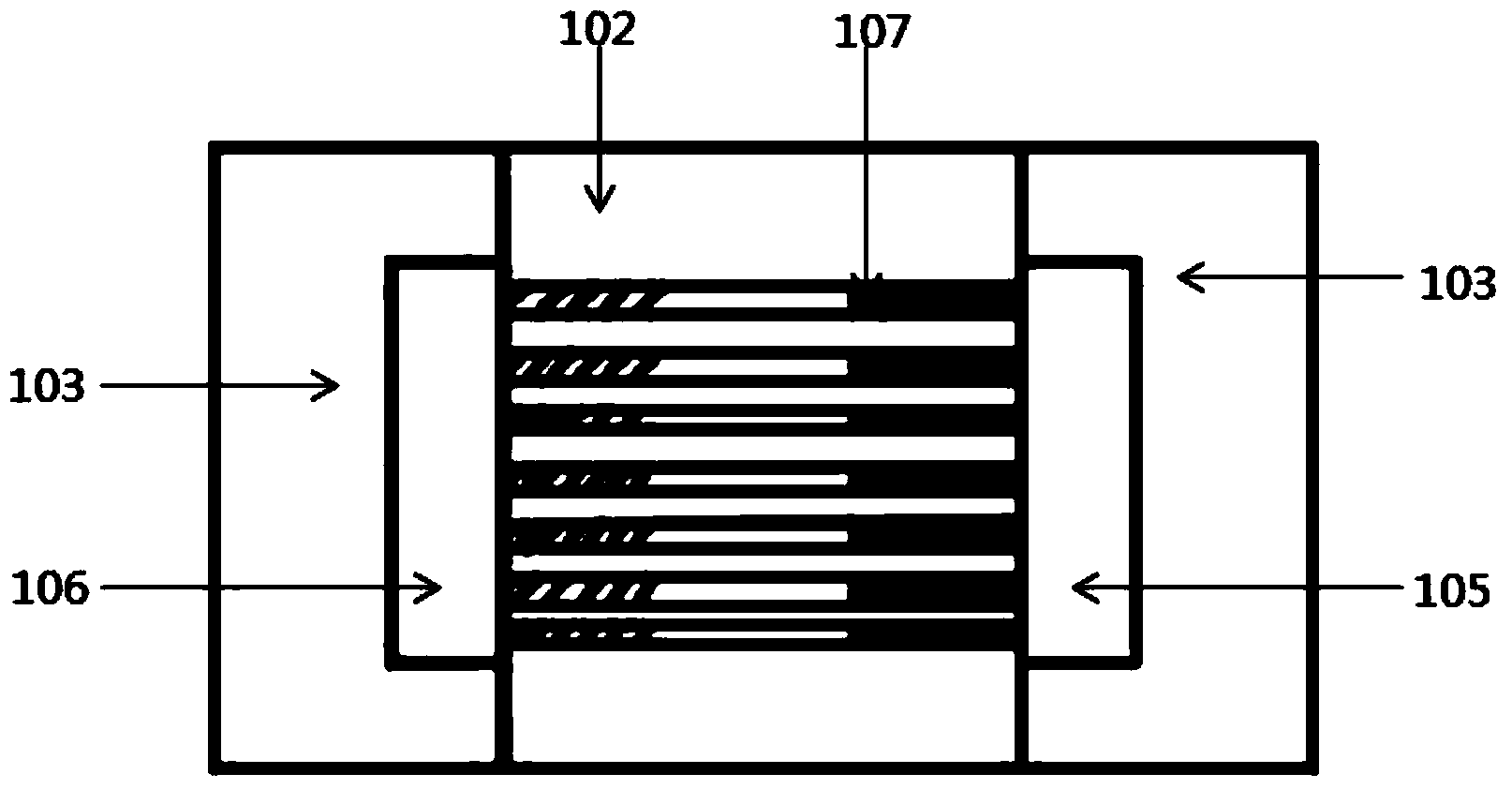

The invention discloses a transverse zinc oxide nanorod array light emitting diode. The transverse zinc oxide nanorod array light emitting diode comprises a sapphire substrate (101), a silicon dioxide insulating layer (102) and a gallium nitride buffer layer (103) which are sequentially arranged from bottom to top. A p-region electrode (106) is arranged on one lateral side of a rectangular etching groove in the gallium nitride buffer layer (103), a piece of blocky n<+>-ZnO (104) is arranged on the other lateral side, opposite to the lateral side, of the rectangular etching groove, and an n-region electrode (105) of an ITO-ZnO film is arranged on the blocky n<+>-ZnO (104). The transverse zinc oxide nanorod array light emitting diode further comprises a ZnO nanorod array (107), an n-type region and a p-type region are arranged at the two ends of the ZnO nanorod array respectively, and meanwhile the ZnO nanorod array is connected with the p-region electrode (106) and the blocky n<+>-ZnO (104) through the p-type region and the n-type region respectively. The transverse zinc oxide nanorod array light emitting diode is high in both light extraction efficiency and electron injection efficiency and meanwhile low in cost.

Owner:SOUTHEAST UNIV

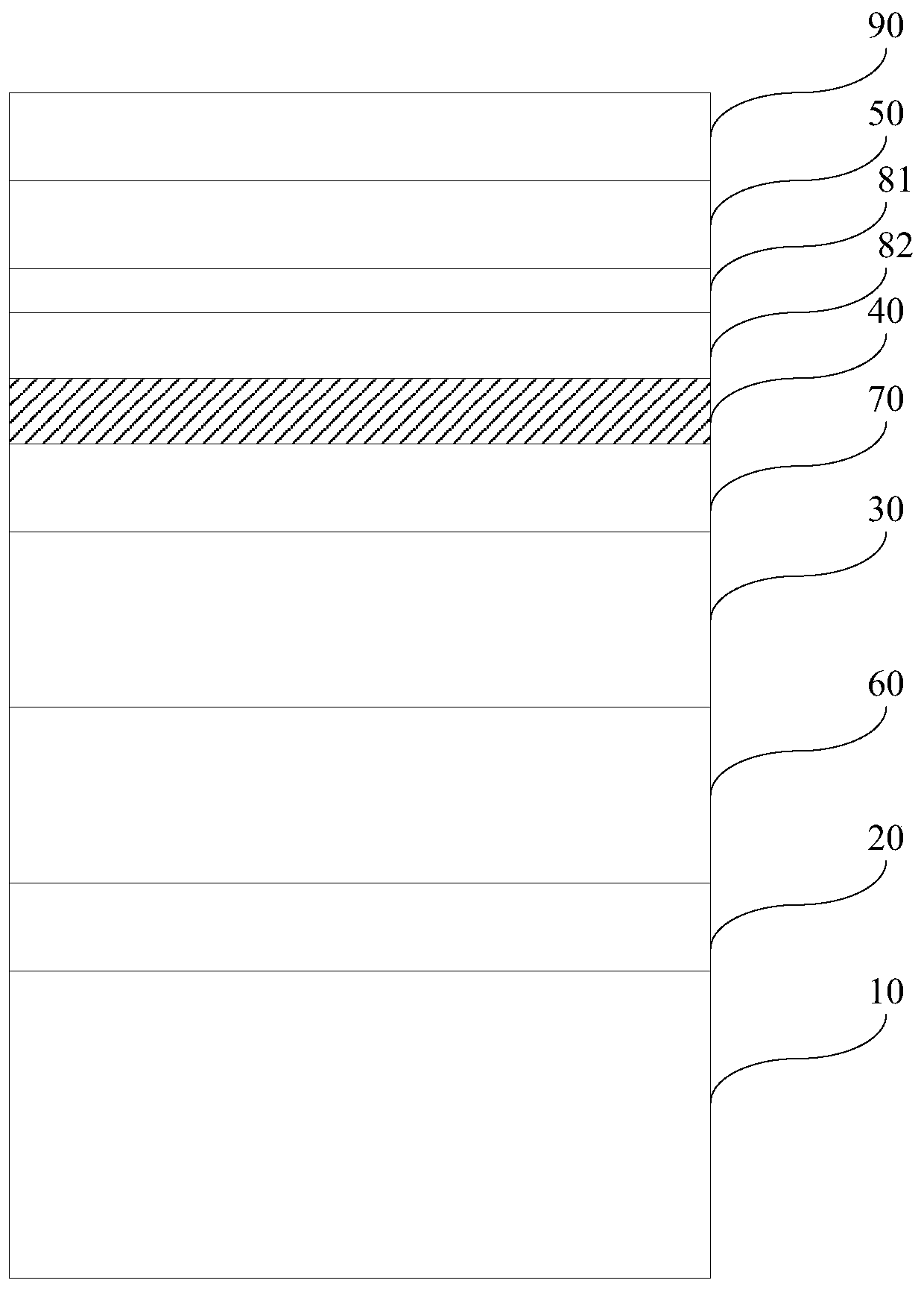

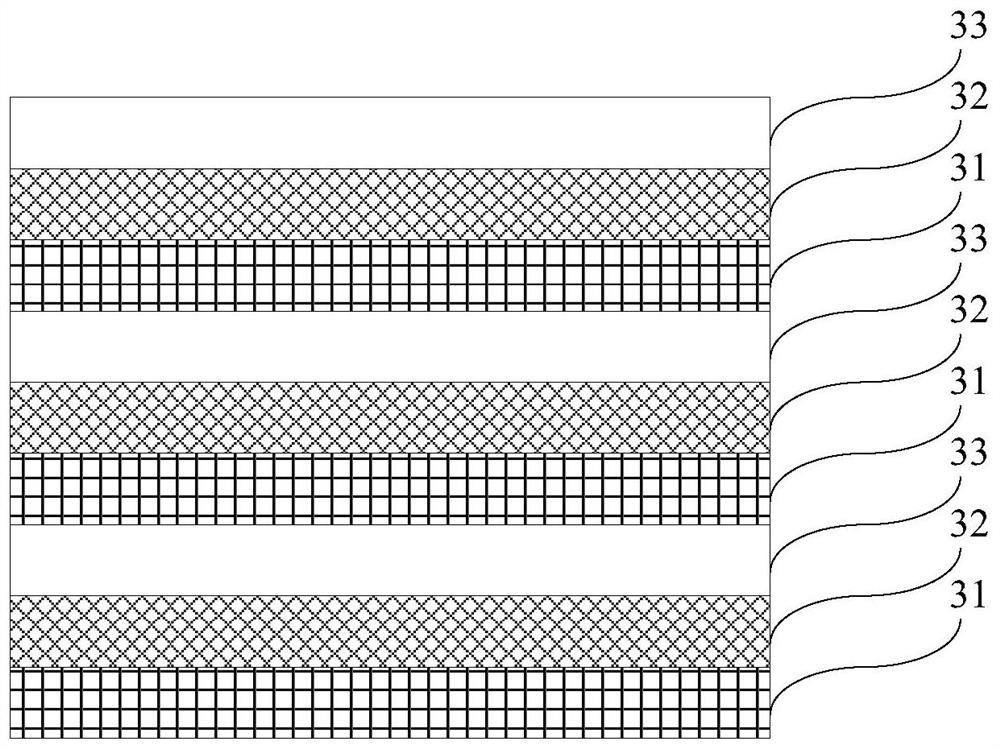

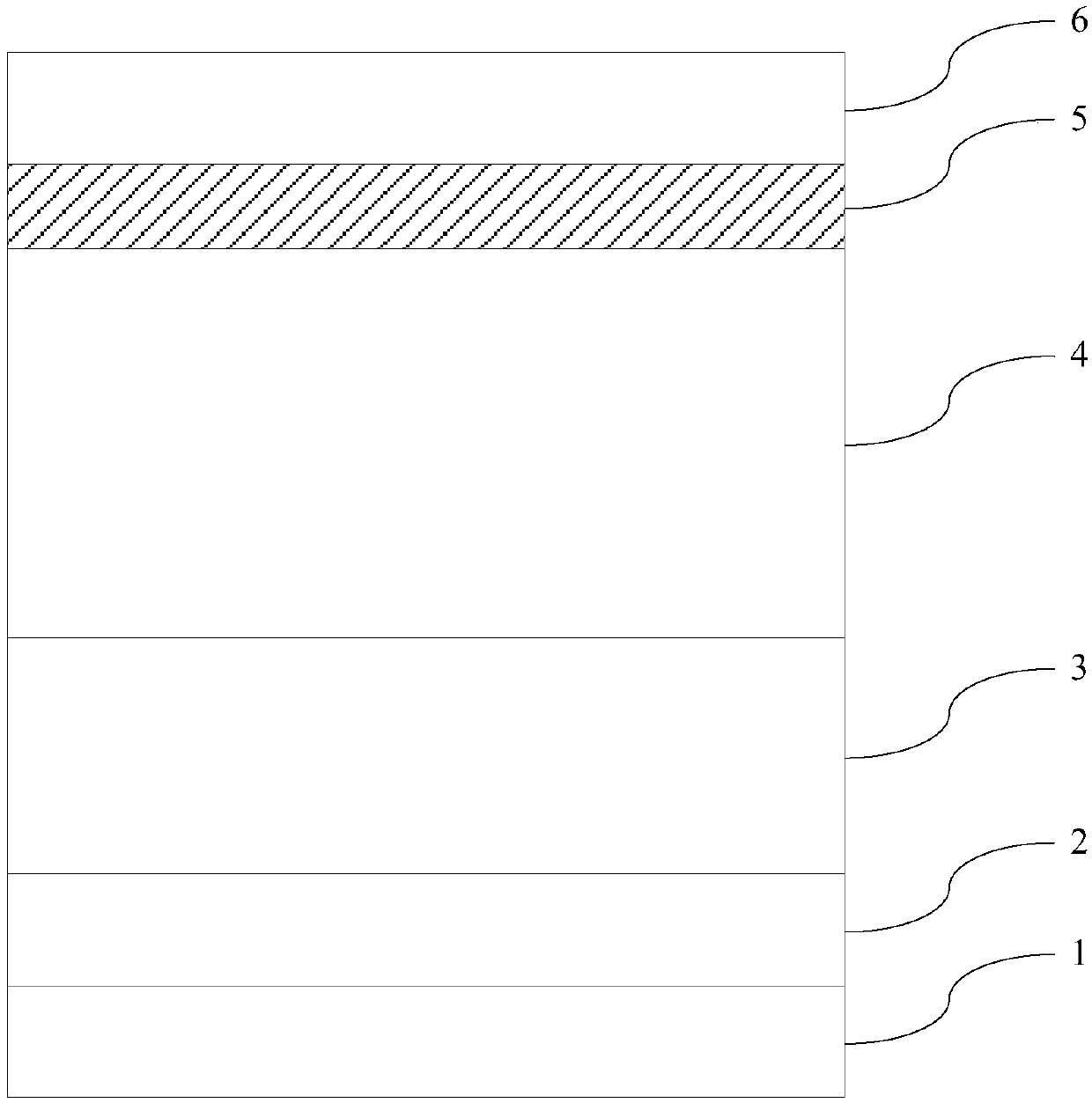

Light-emitting diode epitaxial wafer and manufacturing method thereof

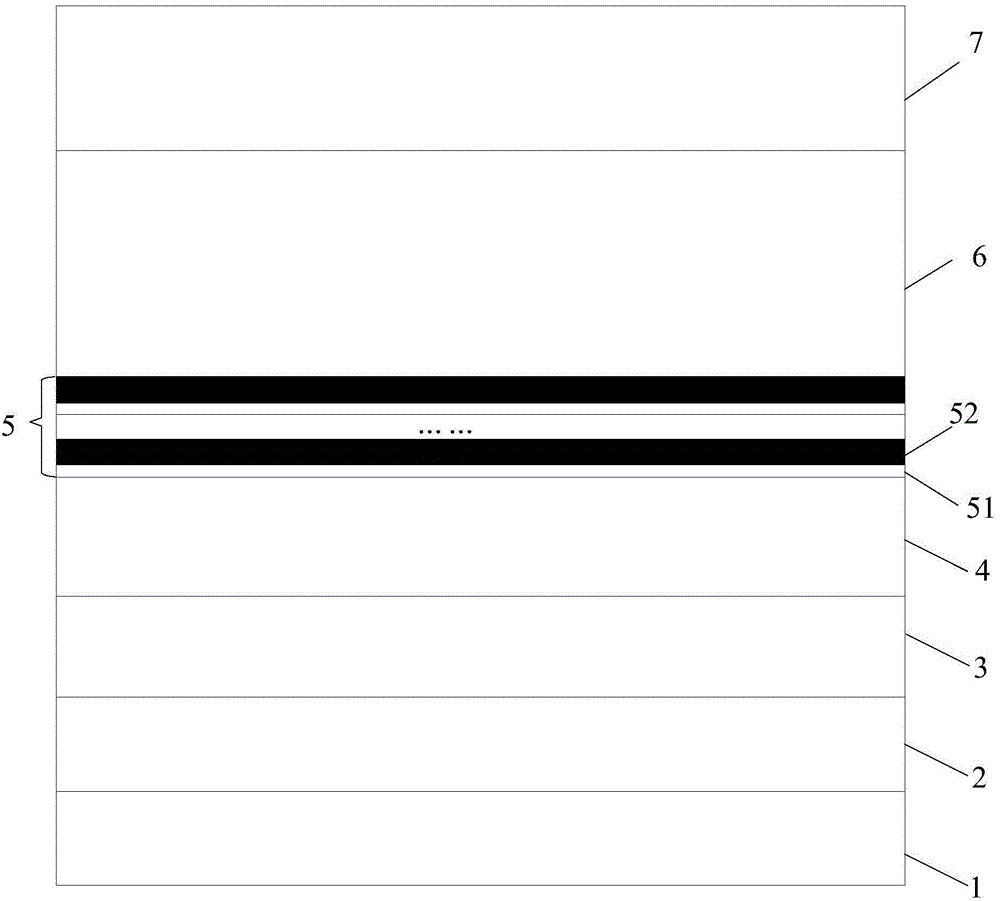

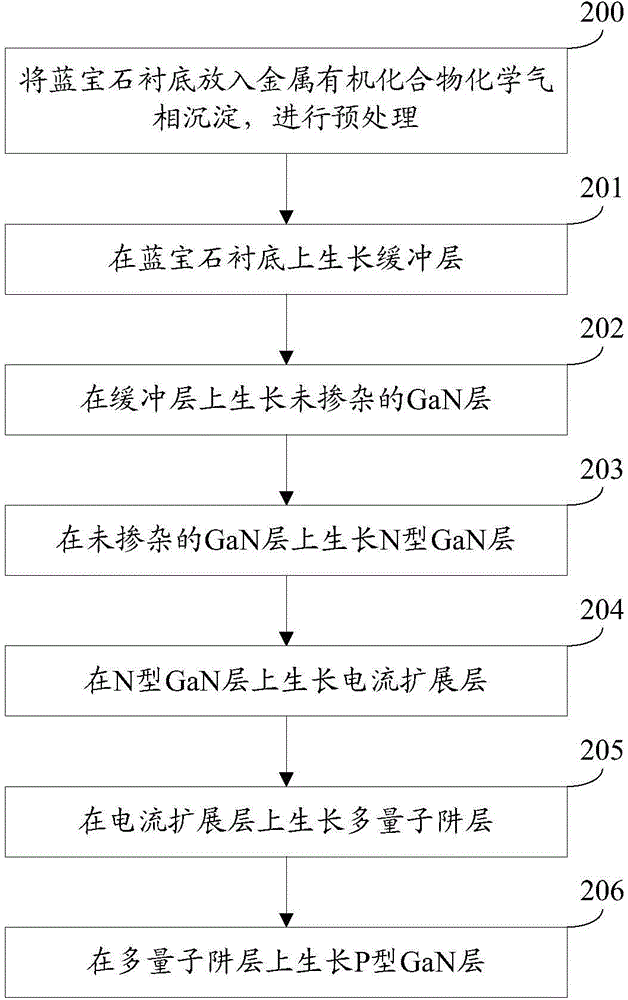

ActiveCN104821356AImprove composite luminous efficiencySemiconductor devicesQuantum wellLattice constant

The invention discloses a light-emitting diode epitaxial wafer and a manufacturing method thereof and belongs to the semiconductor optoelectronic technical field. The light-emitting diode epitaxial wafer includes a sapphire substrate as well as a buffer layer, an undoped GaN layer, an N type GaN layer, a current spreading layer, a multi-quantum well layer and a P type GaN layer which are stacked on the sapphire substrate sequentially; the current spreading layer includes a first sub layer and a second sub layer which are grown alternately; the first sub layer is made of a variable resistance material; the second sub layer is made of N type doped GaN; and the doping concentration of the second sub layer is smaller than that of the N type GaN layer. According to the light-emitting diode epitaxial wafer and the manufacturing method thereof of the invention, the current spreading layer includes the first sub layer and the second sub layer which are grown alternately; the difference of lattice constants of the first sub layer and the second sub layer enables a polarization effect; charge distribution in the current spreading layer is nonuniform, so that an electric field can be formed, and current can be spread under the action of the electric field; and recombined luminescent electrons injected into the multi-quantum well layer are increased, and therefore, the efficiency of recombination luminescence can be improved.

Owner:HC SEMITEK SUZHOU

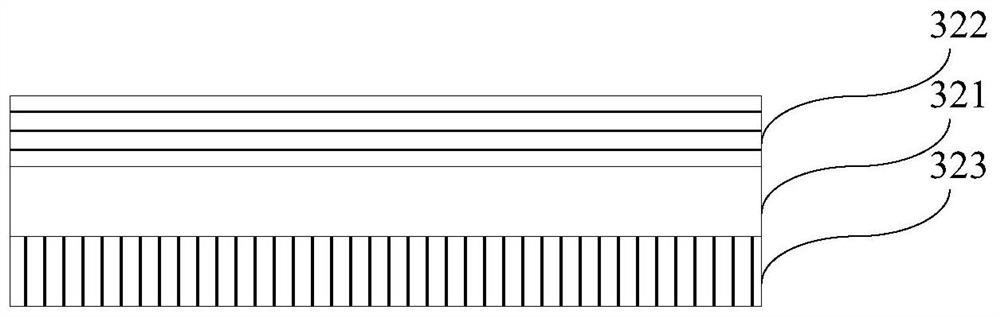

Epitaxial wafer for light-emitting diode, and manufacturing method for epitaxial wafer

ActiveCN107331744AIncrease the number of holesAdd compound glowSemiconductor devicesNon dopedGallium nitride

The invention discloses an epitaxial wafer for a light-emitting diode and a manufacturing method for the epitaxial wafer, and belongs to the technical field of semiconductors. The epitaxial wafer comprises a substrate, a buffering layer, a non-doped gallium nitride layer, an N-type gallium nitride layer, a light-emitting layer and a P-type gallium nitride layer, wherein the buffering layer, the non-doped gallium nitride layer, the N-type gallium nitride layer, the light-emitting layer and the P-type gallium nitride layer are sequentially stacked on the substrate. The light-emitting layer comprises a plurality of quantum well layers and a plurality of quantum barrier layers. The plurality of quantum well layers and the plurality of quantum barrier layers are alternately stacked together. The quantum barrier layers are gallium nitride layers, and at least three quantum well layers, which are the nearest to the N-type gallium nitride layer, of the plurality of quantum well layers are the first quantum well layers. The plurality of quantum well layers, except the first quantum well layers, are the second quantum well layers. The first quantum well layers are non-doped indium gallium nitride layers, and the second quantum well layers comprise P-type doped indium gallium nitride layers. According to the invention, the number of holes in the quantum well layers is increased, and the hole and electron recombination illiumination efficiency is improved.

Owner:HC SEMITEK CORP

Green light emitting diode epitaxial wafer and preparation method thereof

The invention discloses a green light emitting diode epitaxial wafer and a preparation method thereof and belongs to the technical field of a semiconductor. The green light emitting diode epitaxial wafer includes a substrate, an N-type semiconductor layer, an active layer and a P-type semiconductor layer, wherein the N-type semiconductor layer, the active layer and the P type semiconductor layer are sequentially laminated on the substrate, the active layer includes multiple quantum wells and multiple quantum barriers, the multiple quantum wells and the multiple quantum barriers are arranged inan alternate lamination mode, the material of the quantum wells employs non-doped MoS2, and the material of the quantum barriers employs non-doped InxAl1-xN, and the x is greater than 0 and smaller than 0.3. The epitaxial wafer is advantaged in that the non-doped MoS2 is utilized as the material of the quantum wells, the non-doped InxAl1-xN is utilized as the material of the quantum barriers, 0<x<0.3, lattice matching between the InxAl1-xN and the MoS2 is better, and the polarization effect of LEDs can be effectively alleviated.

Owner:HC SEMITEK CORP

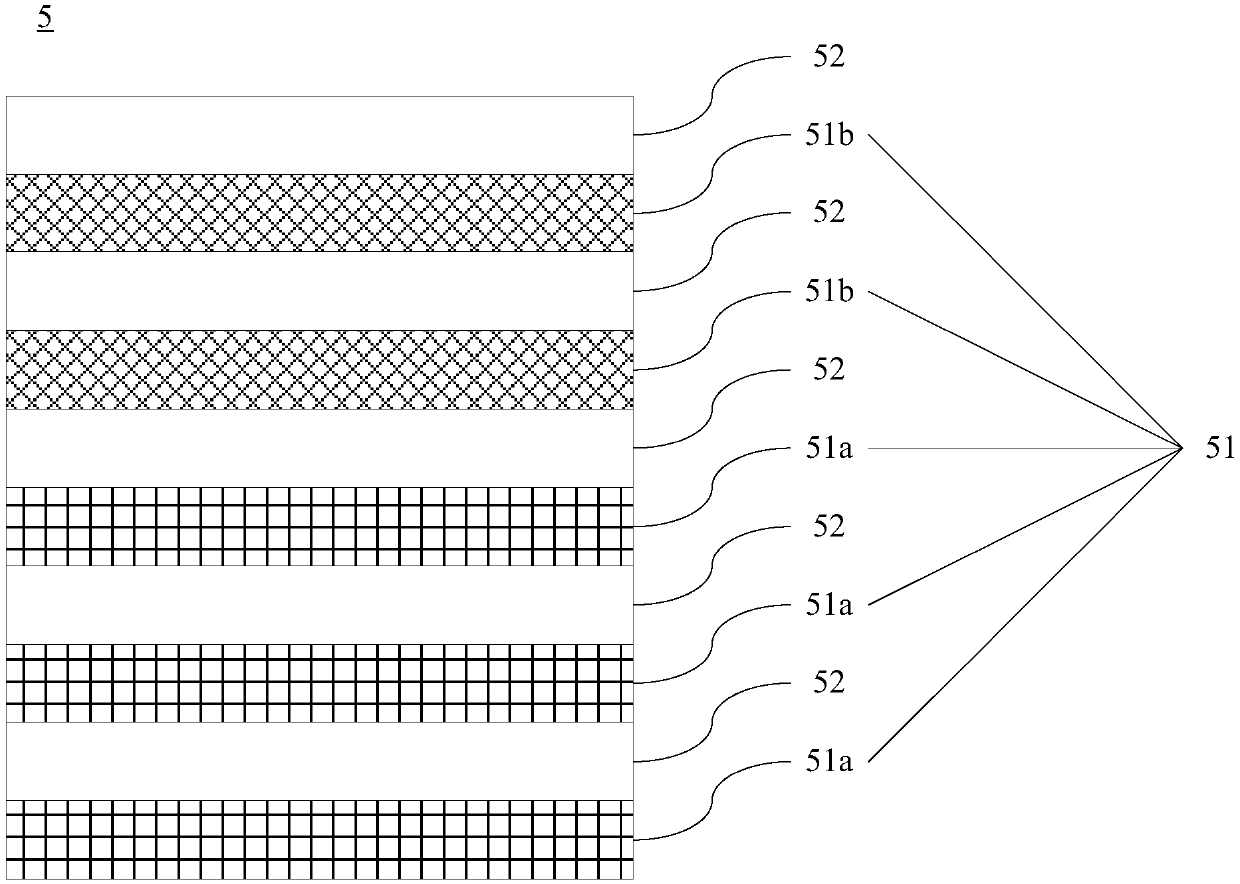

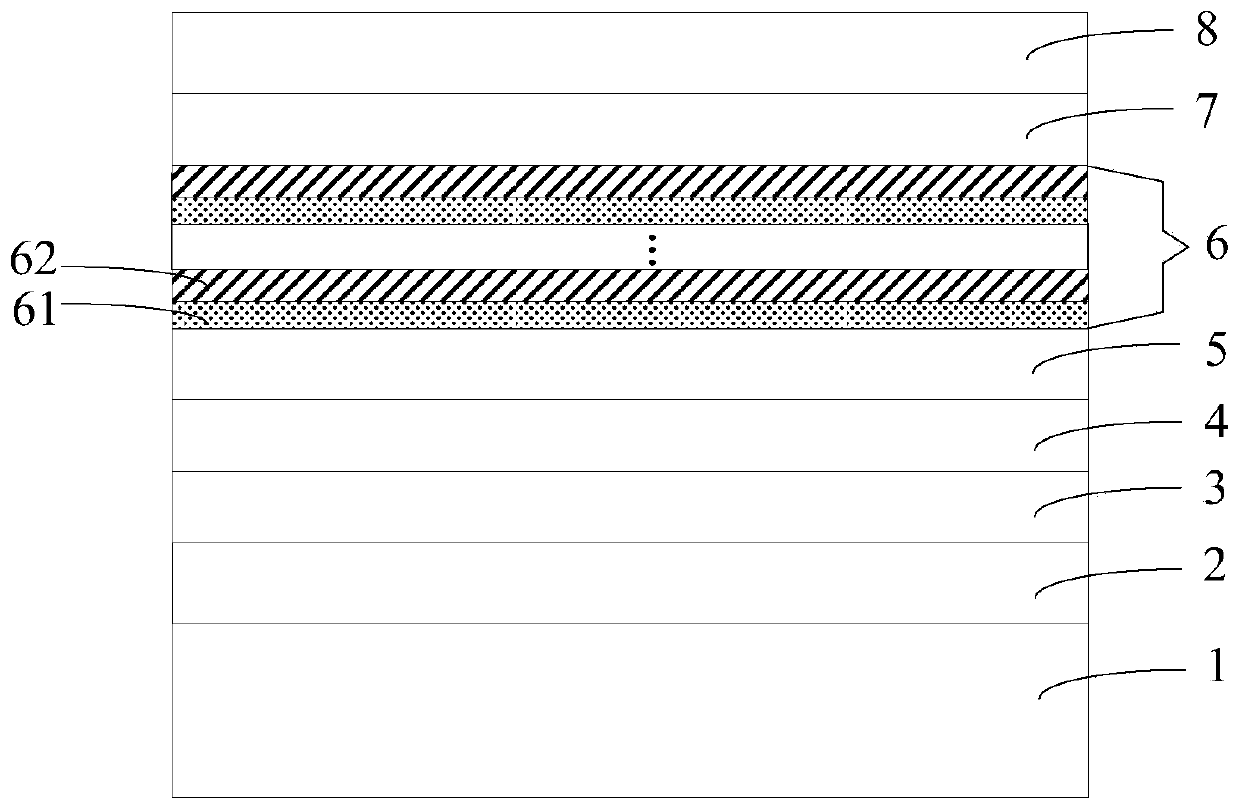

Light-emitting diode epitaxial wafer and manufacture method thereof

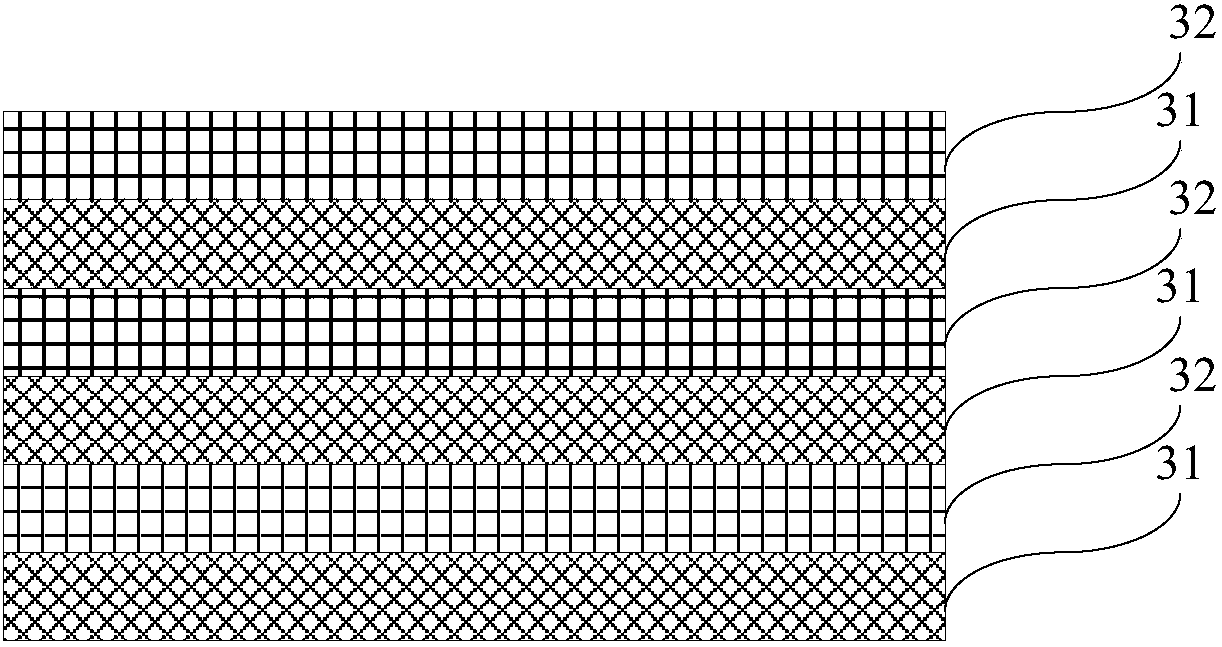

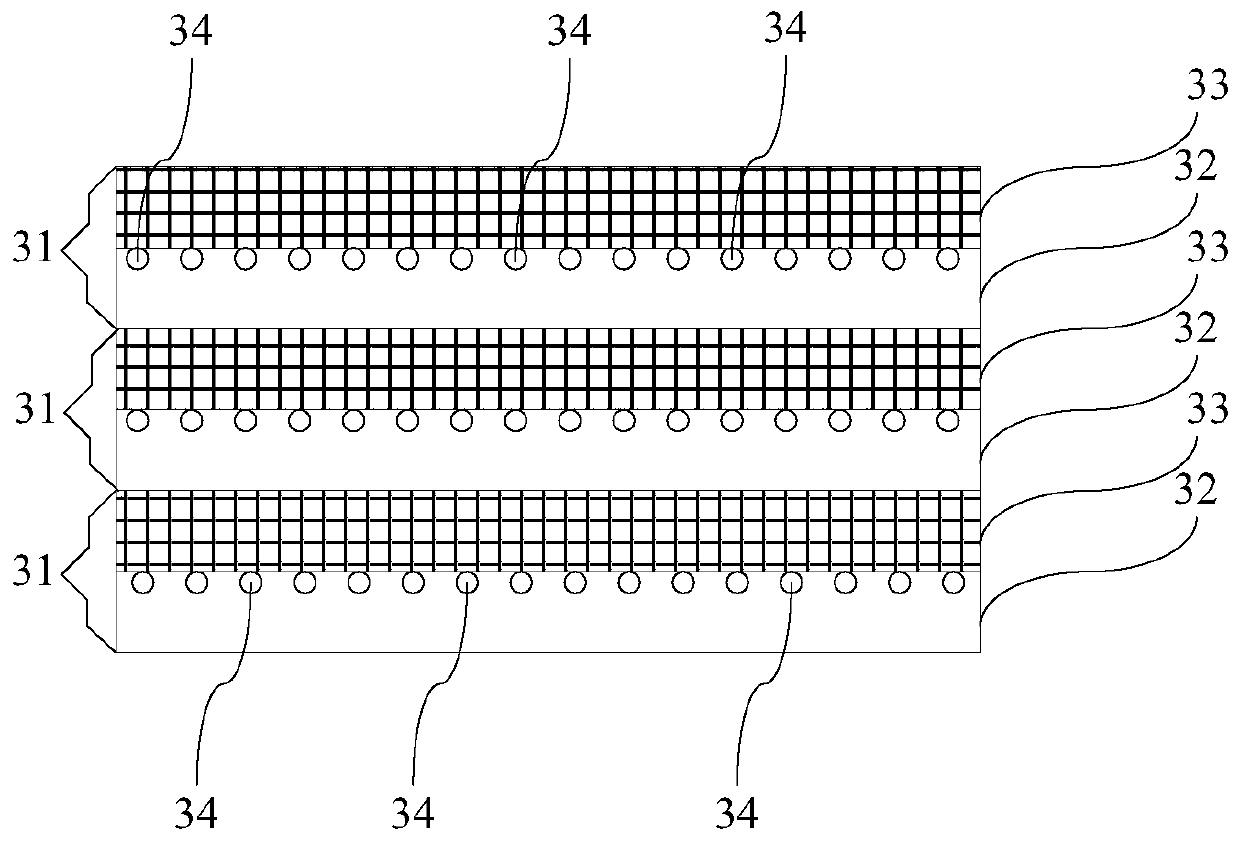

ActiveCN108281519AInhibit migrationBlocking aggregationSemiconductor devicesActivation energyQuantum well

The invention discloses a light-emitting diode epitaxial wafer and a manufacture method thereof and belongs to the technical field of semiconductors. The light-emitting diode epitaxial wafer comprisesan electronic barrier layer that includes superlattice structure of N cycles; the superlattice structure of each cycle includes an InxGa1-xN layer and an AlyG1-yN layer, wherein the InxGa1-xN layer is formed by growth at 900-950 DEG C; lattice quality of a multi-quantum well layer can be improved, composite light-emitting efficiency of electrons and holes in the multi-quantum well layer can be improved. In addition, the presence of In brings down activation energy of Mg and increases hole concentration of a P-type layer. Each AlyG1-yN layer is formed by growth at 950-980 DEG C, barrier heightof the AlyG1-yN layer is increased, and electrons are avoided overflowing to the P-type layer; the content of Al gradually decreases or increases, so that electrons can be avoided overflowing to theP-type layer at the premise of reducing the blocking action of holes, and light-emitting efficiency of a diode is improved.

Owner:HC SEMITEK SUZHOU

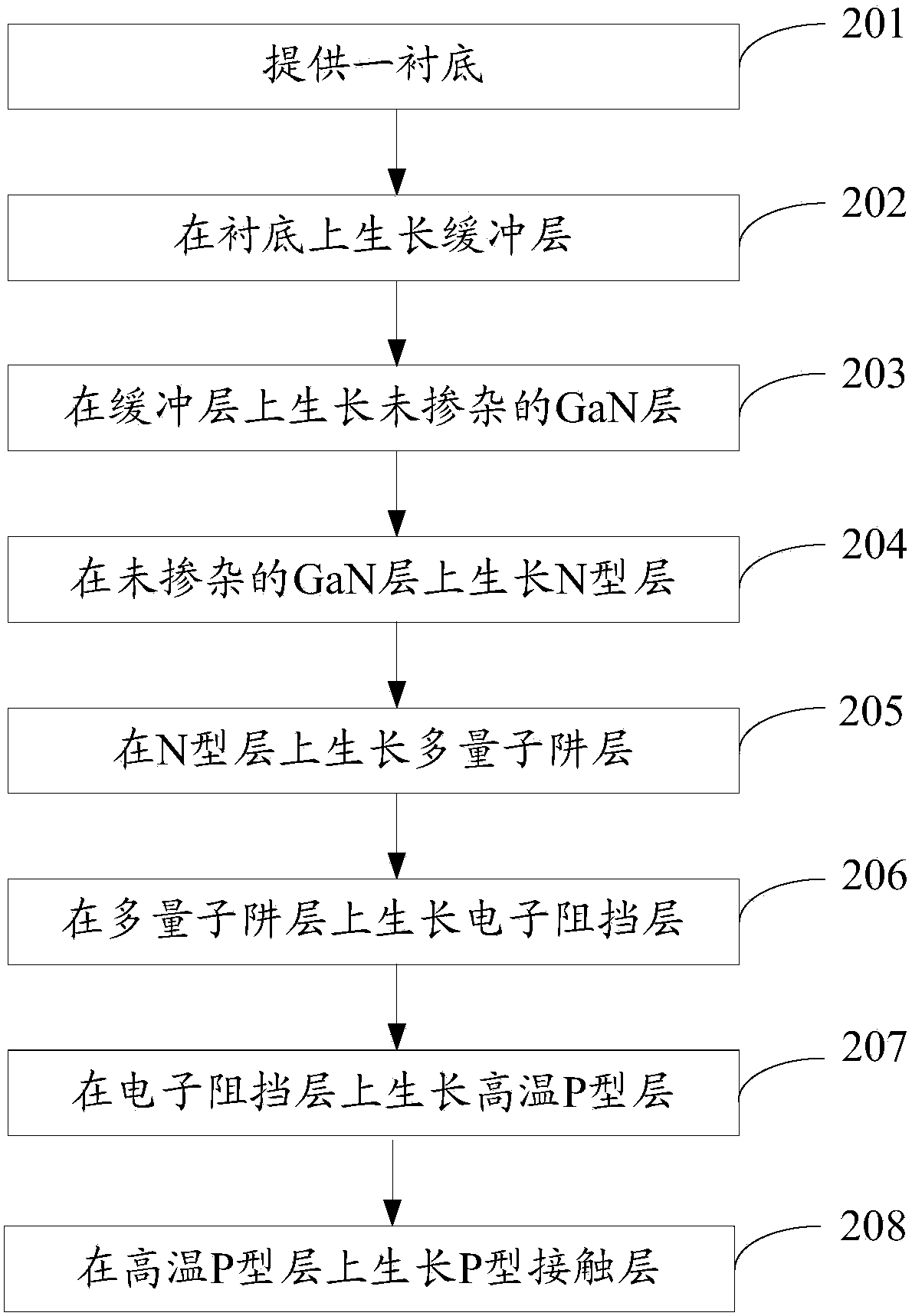

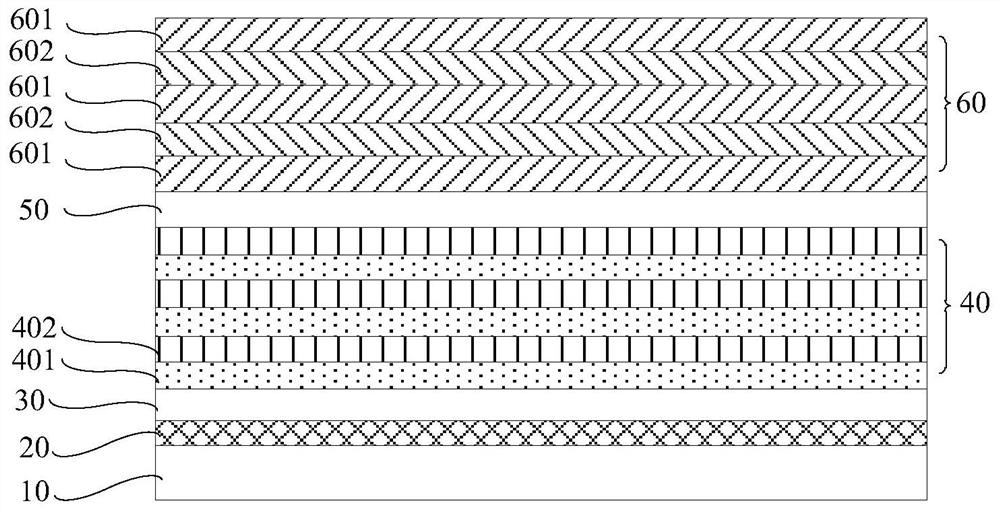

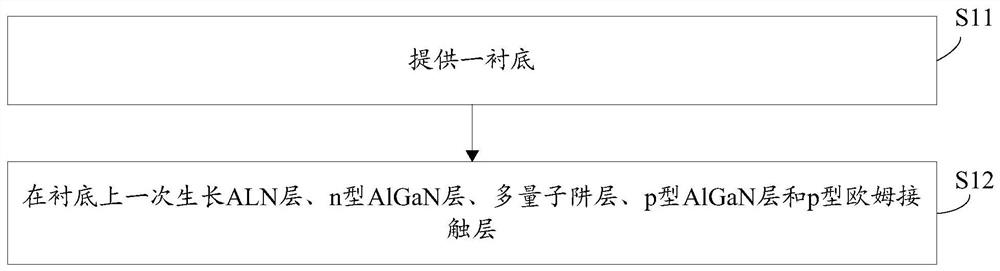

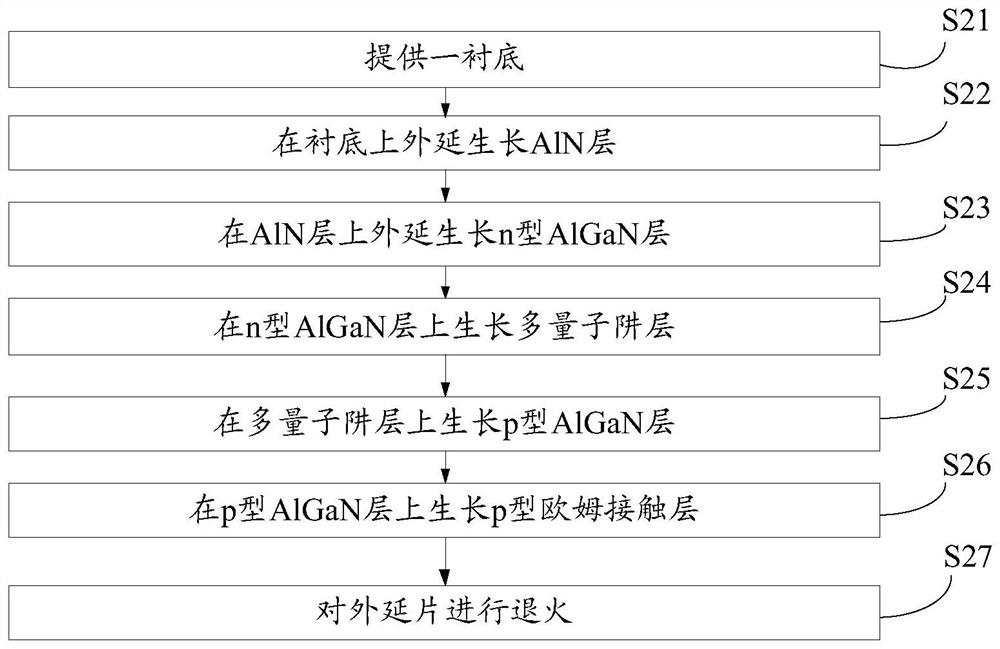

Epitaxial wafer of AlGaN-based deep ultraviolet light emitting diode and preparation method thereof

ActiveCN113571616AIncrease migration rateIncrease the doping concentrationSemiconductor devicesHexagonal boron nitrideLattice mismatch

The invention provides an epitaxial wafer of an AlGaN-based deep ultraviolet light emitting diode and a preparation method of the epitaxial wafer, and belongs to the technical field of photoelectron manufacturing. The epitaxial wafer comprises a substrate, and an AlN layer, an n-type AlGaN layer, a multi-quantum well layer, a p-type AlGaN layer and a p-type ohmic contact layer which are sequentially formed on the substrate; the p-type ohmic contact layer comprises a plurality of p-type GaN layers and a plurality of hexagonal boron nitride layers which are sequentially and alternately stacked, and the doping concentration of each p-type GaN layer is increased layer by layer along the growth direction of the epitaxial wafer. According to the embodiment of the invention, the conductivity of the p-type layer can be improved, and the problem of lattice mismatching between the AlGaN layer and the p-type GaN layer is relieved, so that the crystal quality of the p-type layer is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

OLED device

InactiveCN109390441AReduce the driving voltageImprove power efficiencyMaterial nanotechnologyNanoopticsQuantum dotHole transport layer

The present invention provides a QLED device comprising a bottom electrode, a bipolar Auger energy multiplying structure and a top electrode, wherein the bottom electrode, a bipolar Auger energy multiplying structure and the top electrode are sequentially laminated on a substrate, and the bipolar Auger energy multiplying structure comprises a hole transport layer, a quantum dot light-emitting layer and an electron transport layer, and the hole transport layer, the quantum dot light-emitting layer and the electron transport layer are sequentially bonded. The electron transport layer is made ofan n-type nano material, and the hole transport layer is made of a p-type nano material.

Owner:TCL CORPORATION

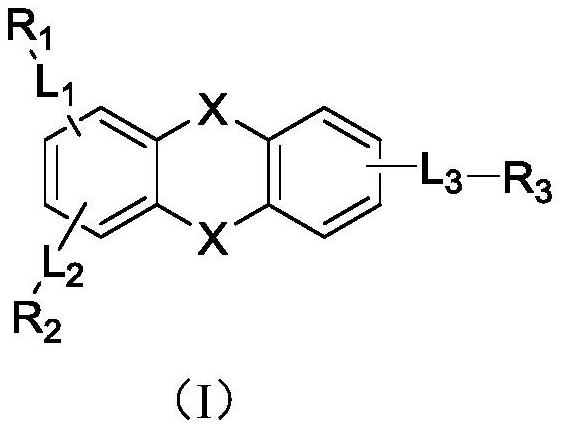

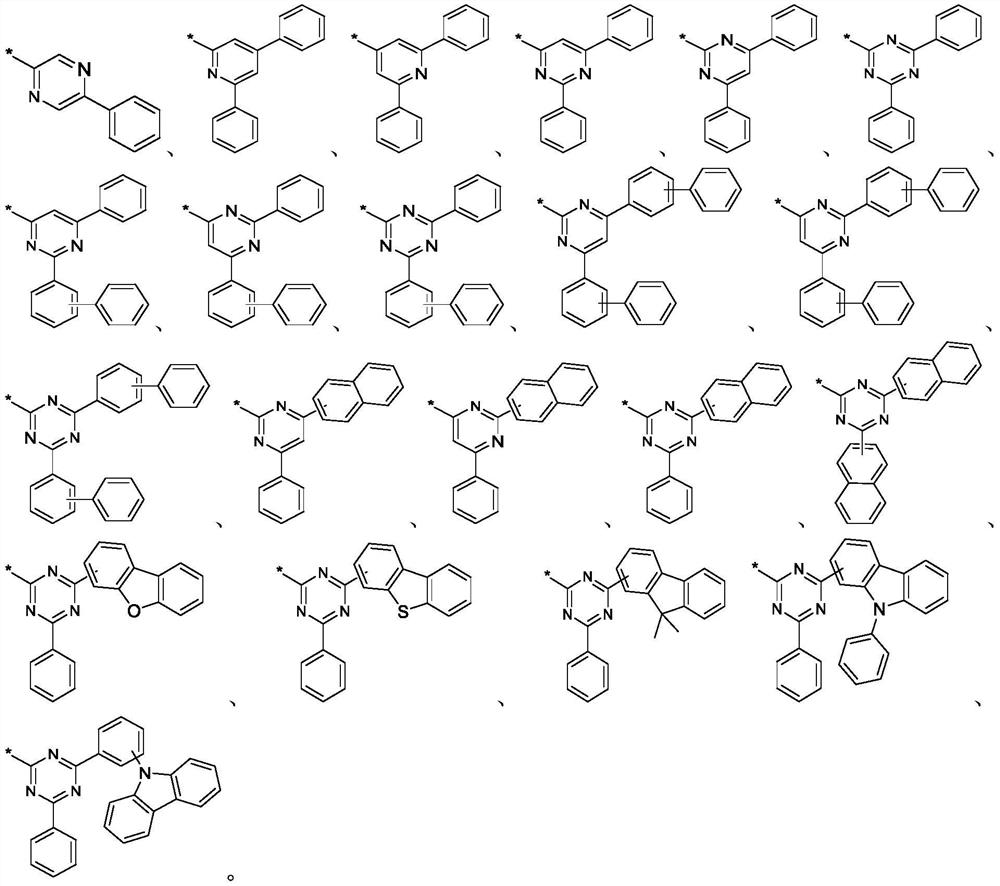

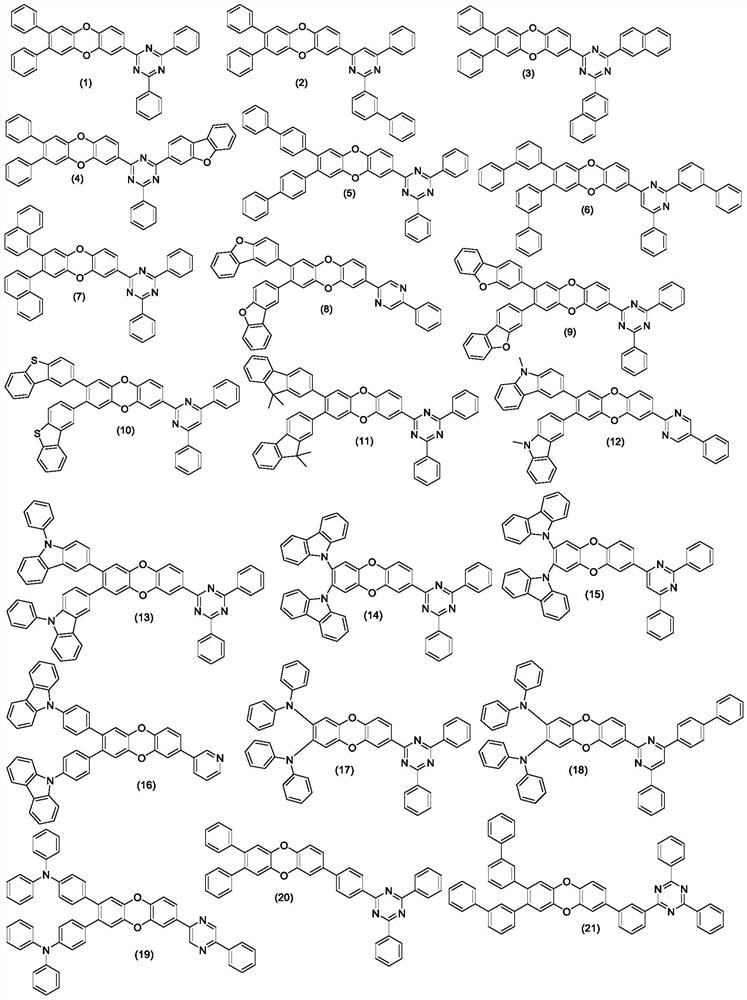

Heteroanthracene derivative and application thereof, and organic electroluminescent device

ActiveCN112390778AIncrease the starting voltageImprove current efficiencyGroup 5/15 element organic compoundsSolid-state devicesElectron holeHost material

The invention discloses a heteroanthracene derivative and a preparation method and application thereof, and an organic electroluminescent device. According to the heteroanthracene derivative, at leastone site selected from site 2, site 3 and site 7 of a heteroanthracene group is substituted by a hole transport type group, and the heteroanthracene derivative has a parent nucleus structure of heteroanthracene, so a D-A type compound or a hole transport type compound with a star-shaped spatial configuration is formed; the substitution of multi-site aromatic groups and the star-shaped configuration enable the derivative to have better stability and a balanced electron / hole transport rate in device preparation and application; and as a light-emitting host material or hole transport material ofan organic light-emitting device, the derivative has higher quantum recombination efficiency, can effectively solve the problems of electron / hole imbalance and easy crystallization in a device, emitspurer light color, and has more remarkable advantages than similar compounds and compounds in the prior art in the aspects of starting voltage, current efficiency, service life and thermal stability.

Owner:湖北尚赛光电材料有限公司

A lateral ZnO nanorod array light-emitting diode

ActiveCN104051589BHigh light transmittanceImprove optical output powerMaterial nanotechnologySemiconductor devicesEtchingElectron injection

The invention discloses a transverse zinc oxide nanorod array light emitting diode. The transverse zinc oxide nanorod array light emitting diode comprises a sapphire substrate (101), a silicon dioxide insulating layer (102) and a gallium nitride buffer layer (103) which are sequentially arranged from bottom to top. A p-region electrode (106) is arranged on one lateral side of a rectangular etching groove in the gallium nitride buffer layer (103), a piece of blocky n<+>-ZnO (104) is arranged on the other lateral side, opposite to the lateral side, of the rectangular etching groove, and an n-region electrode (105) of an ITO-ZnO film is arranged on the blocky n<+>-ZnO (104). The transverse zinc oxide nanorod array light emitting diode further comprises a ZnO nanorod array (107), an n-type region and a p-type region are arranged at the two ends of the ZnO nanorod array respectively, and meanwhile the ZnO nanorod array is connected with the p-region electrode (106) and the blocky n<+>-ZnO (104) through the p-type region and the n-type region respectively. The transverse zinc oxide nanorod array light emitting diode is high in both light extraction efficiency and electron injection efficiency and meanwhile low in cost.

Owner:SOUTHEAST UNIV

An ultraviolet light emitting diode with a composite electron blocking layer structure

ActiveCN105977356BPrevent overflowImprove composite luminous efficiencySemiconductor devicesQuantum wellUltraviolet lights

The invention discloses a UV light emitting diode with a compound electronic barrier layer structure. The light emitting diode, successively from the bottom to the top, includes a substrate (101), a low-temperature AlN nucleation layer (102), a high-temperature AlN buffer layer (103), an n type AlGaN layer (104), an Al<x>Ga<1-x>N / Al<y>Ga<1-y>N multi-quantum well active region (105), and a p-AlsIntGa1-s-tN / p-AlzGa1-zN compound electronic barrier layer (106) consisting of a p-Al<s>In<t>Ga<1-s-t> layer (106) and a p-Al<z>Ga<1-z>N layer. The diode provided can solve the problem that a conventional electronic barrier layer structure generates a parasitic electronic inversion layer between the last quantum well barrier and an electronic barrier layer.

Owner:SOUTHEAST UNIV

A kind of growth method of light-emitting diode epitaxial wafer and epitaxial wafer

The invention discloses a growth method for a light-emitting diode epitaxial wafer and an epitaxial wafer, belonging to the technical field of a semiconductor. The growth method comprises the following steps of: sequentially growing a low-temperature buffer layer, a non-doped GaN layer and an N-type layer on a substrate; alternatively growing a first InGaN pit layer and a first GaN barrier layer on the N-type layer to form a first active layer; alternatively growing a second InGaN pit layer and a second GaN barrier layer on the first active layer to form a second active layer; and sequentially growing an electron blocking layer and a P-type layer on the second active layer, wherein the growth pressure of the second active layer is lower than the growth pressure of the first active layer, the growth speed of the second active layer is lower than the growth speed of the first active layer, the thickness of the second active layer is smaller than the thickness of the first active layer, and the growth pressure, the growth speed and the thickness of the second InGaN pit layer are gradually reduced, slowed and decreased along the growth direction of the light-emitting diode epitaxial wafer. The epitaxial wafer is high in luminous efficiency.

Owner:HC SEMITEK SUZHOU

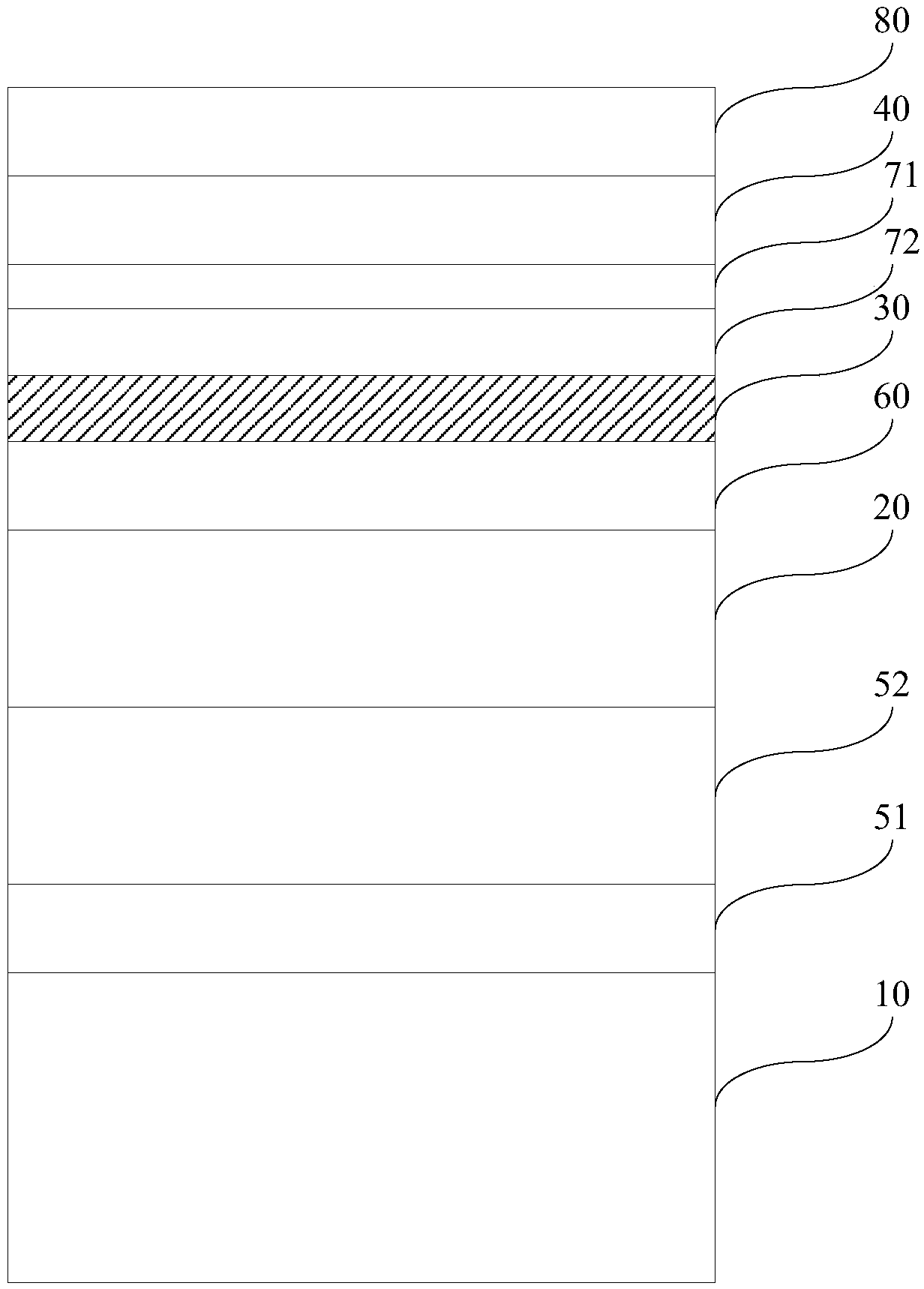

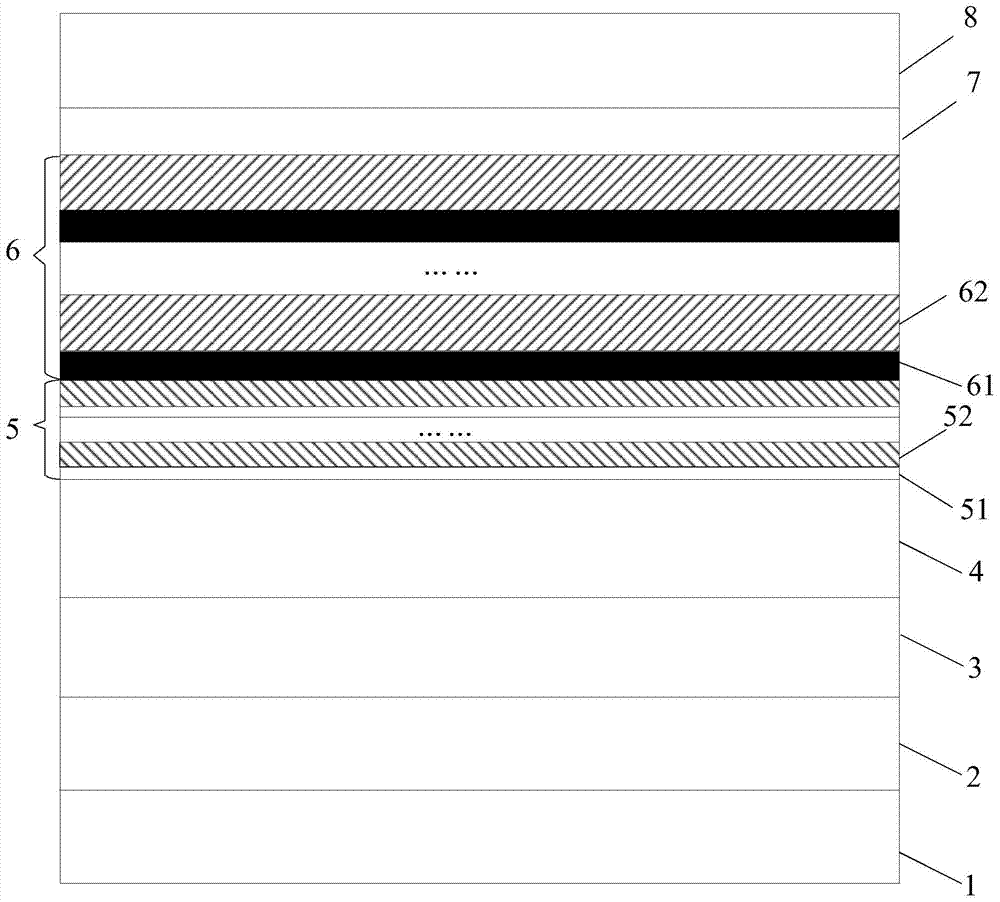

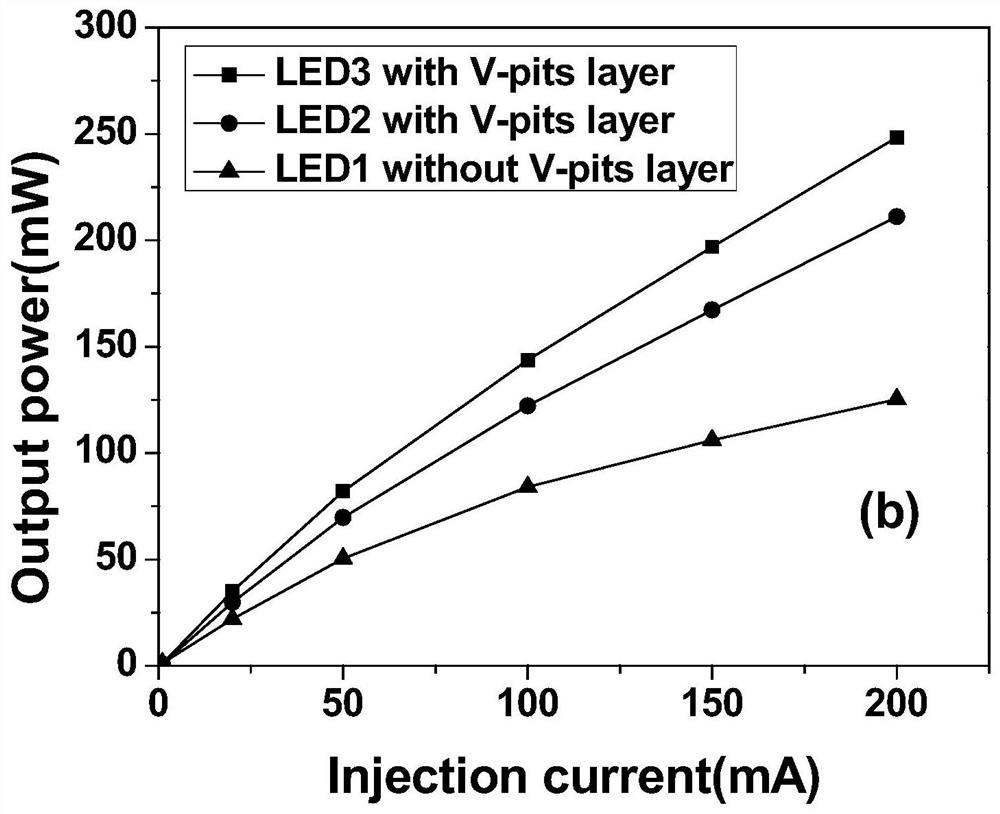

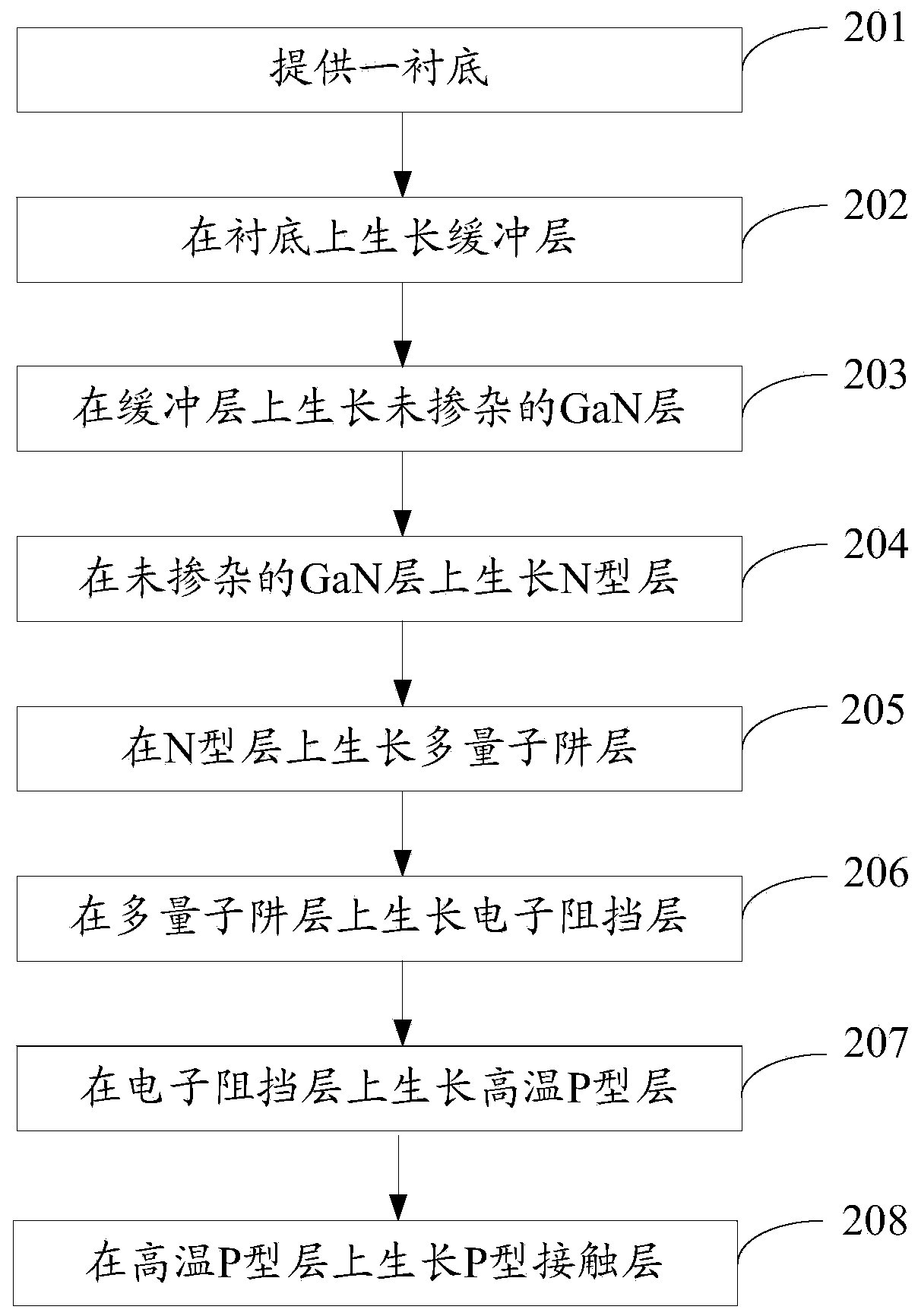

A kind of high-brightness light-emitting diode based on Aln/PSS composite substrate and preparation method thereof

ActiveCN110729383BReduce dislocation densityDislocation maskingSemiconductor devicesPhysical chemistryComposite substrate

The invention discloses a high-brightness light-emitting diode based on an AIN / PSS composite substrate and a preparation method of the high-brightness light-emitting diode. The high-brightness light-emitting diode comprises the AlN / PSS composite substrate, a u-type GaN merging layer, an n-type GaN layer, a low-temperature GaN V-pits layer, an active region, an electron blocking layer, a high-temperature p-type GaN layer and a contact layer which are sequentially stacked from bottom to top. The high-brightness light-emitting diode provided by the invention comprises the u-GaN merging layer of anovel structure, the V-pits layer and the active region; and therefore, the crystal quality of an epitaxial layer can be effectively improved, the stress of the active region can be effectively relieved, current expansion in a horizontal direction can be improved, the light-emitting efficiency of the light-emitting diode can be improved, and the brightness of the prepared light-emitting diode ishigh.

Owner:DONGGUAN UNIV OF TECH

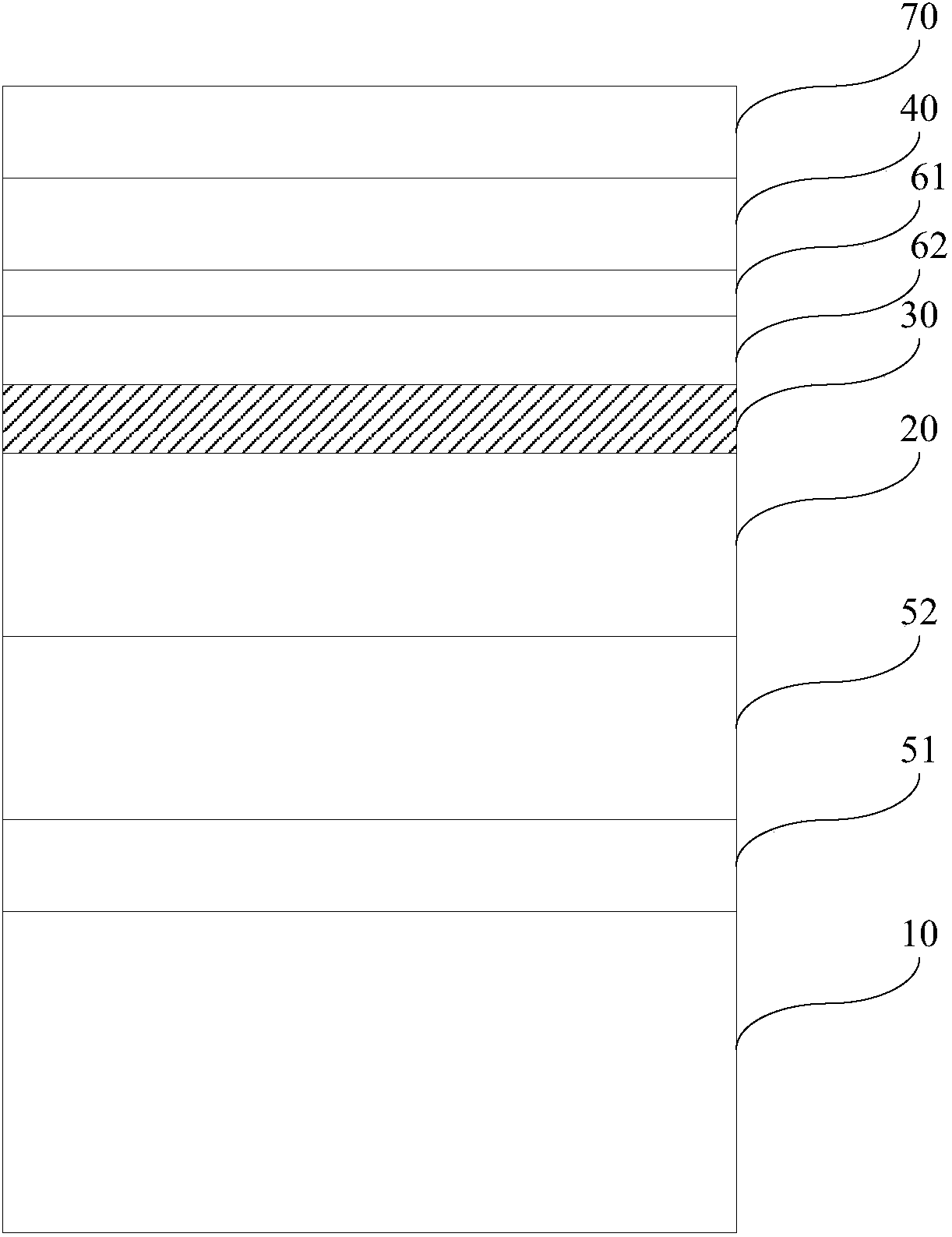

A gallium nitride-based light-emitting diode epitaxial wafer and its preparation method

ActiveCN109346577BImprove composite luminous efficiencyImprove luminous efficiencySemiconductor devicesGallium nitrideLight-emitting diode

Owner:HC SEMITEK ZHEJIANG CO LTD

A gallium nitride-based light-emitting diode epitaxial wafer and its preparation method

ActiveCN109473522BPrevent junction temperature riseImprove composite luminous efficiencySemiconductor devicesJunction temperatureGallium nitride

The invention discloses a gallium nitride-based light emitting diode epitaxial wafer and a preparation method thereof, and belongs to the technical field of semiconductors. The gallium nitride-based light emitting diode epitaxial wafer comprises a substrate, a buffer layer, an N-type semiconductor layer, an active layer, and a P-type semiconductor layer, and the buffer layer, the N-type semiconductor layer, the active layer, and the P-type semiconductor layer are sequentially stacked on the substrate; the active layer comprises a plurality of quantum wells and a plurality of quantum barriers,and the plurality of quantum wells and the plurality of quantum barriers are alternately stacked; and at least one boron hydride layer is inserted into the quantum barrier. According to the epitaxialwafer and the preparation method in the invention, at least one boron hydride layer is inserted into the quantum barrier, and the thermal conductivity of the boron hydride layer is good, so the heat generated by combined luminescence of electrons and holes in the active layer can be conducted out in time to prevent the junction temperature of the active layer from rising, thereby facilitating theimprovement of combined luminous efficiency of the electrons and holes, and further improving the luminous efficiency of the LED, and the gallium nitride-based light emitting diode epitaxial wafer isparticularly suitable for LEDs at a high current density.

Owner:HC SEMITEK ZHEJIANG CO LTD

A light-emitting diode epitaxial wafer and its preparation method

ActiveCN109346576BReduce heterojunction mismatchImprove crystal qualitySemiconductor devicesIndiumActive layer

Owner:HC SEMITEK ZHEJIANG CO LTD

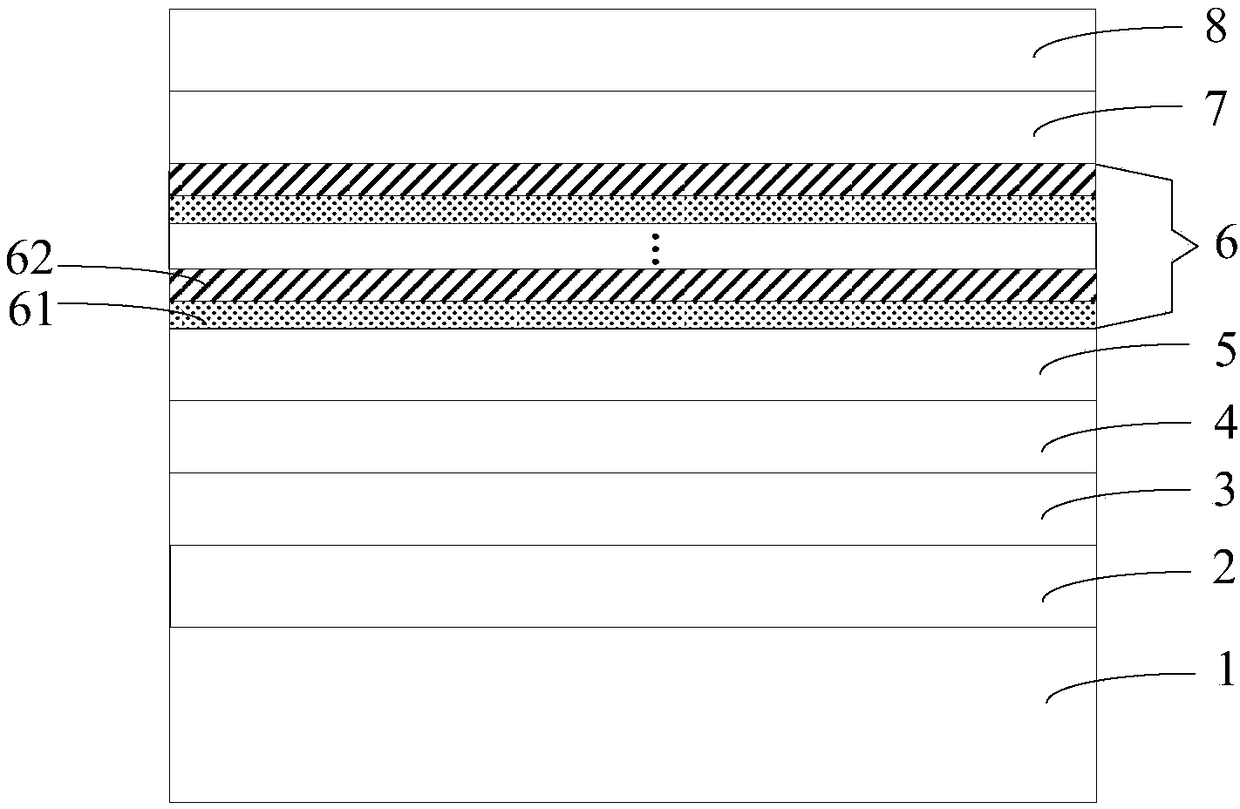

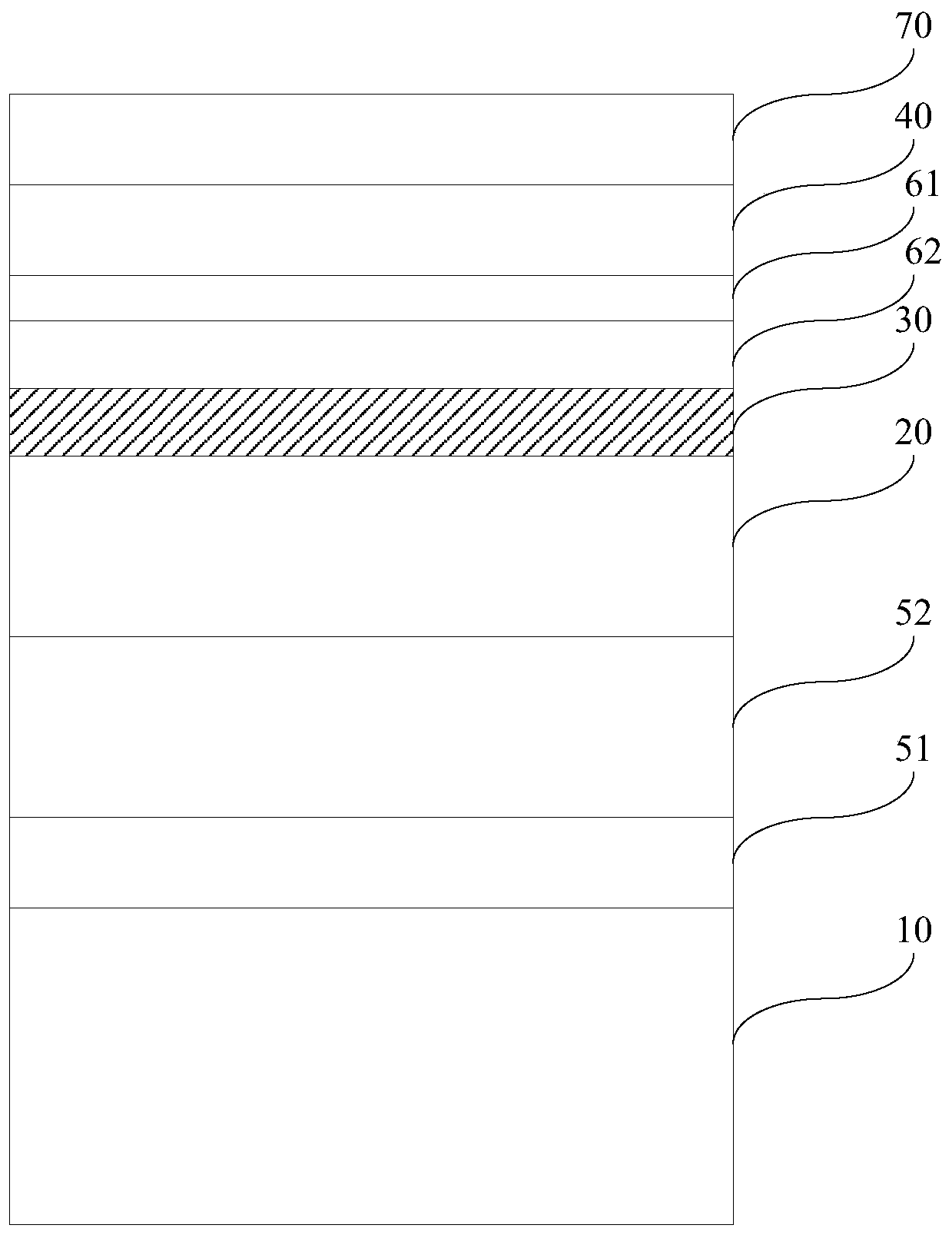

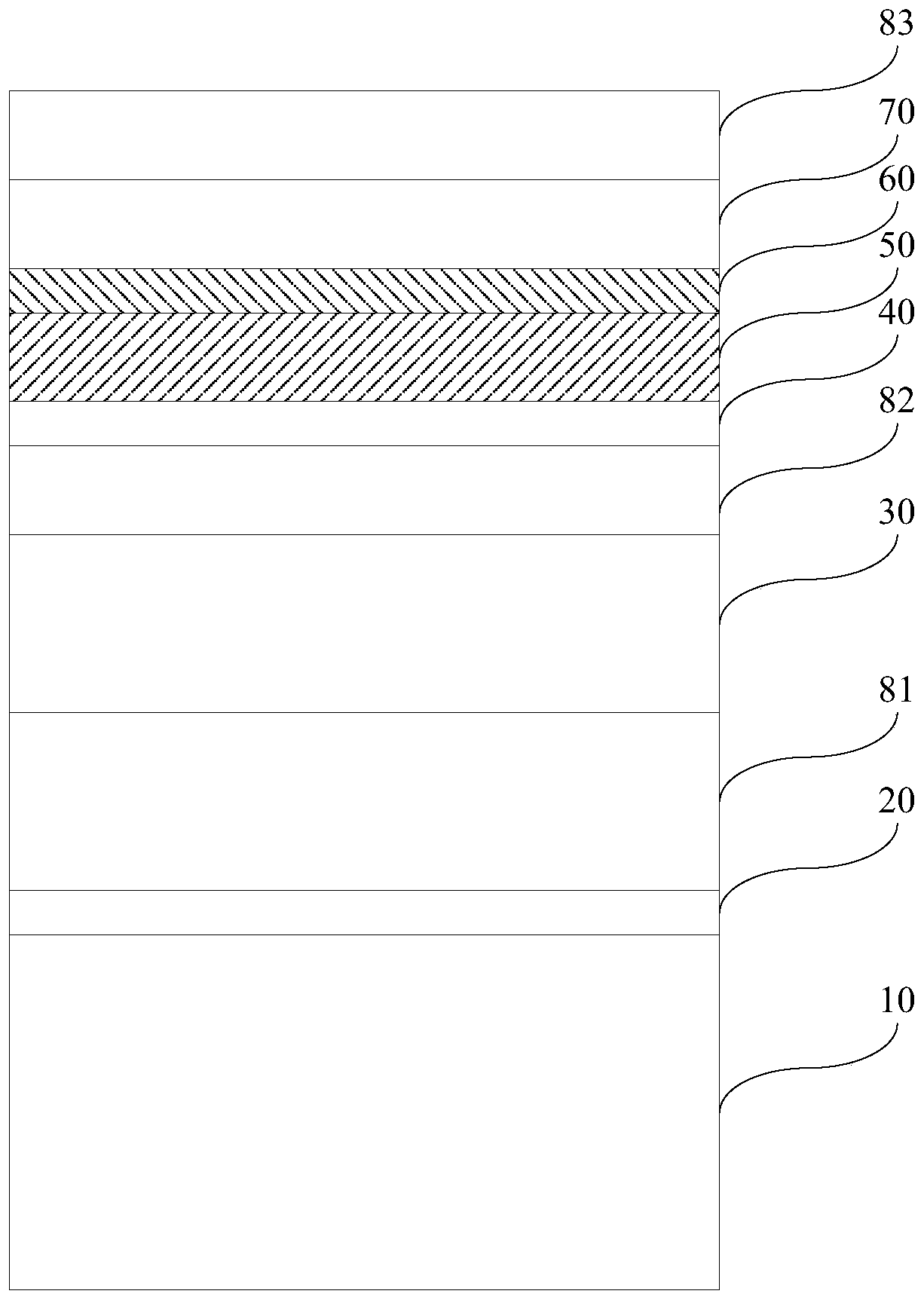

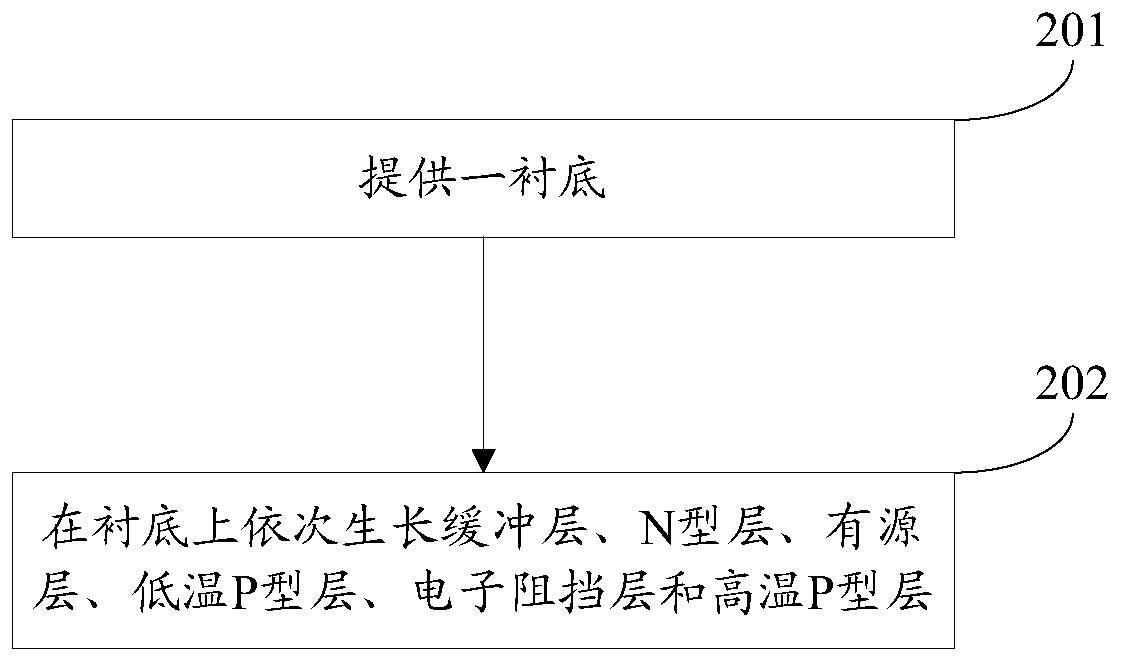

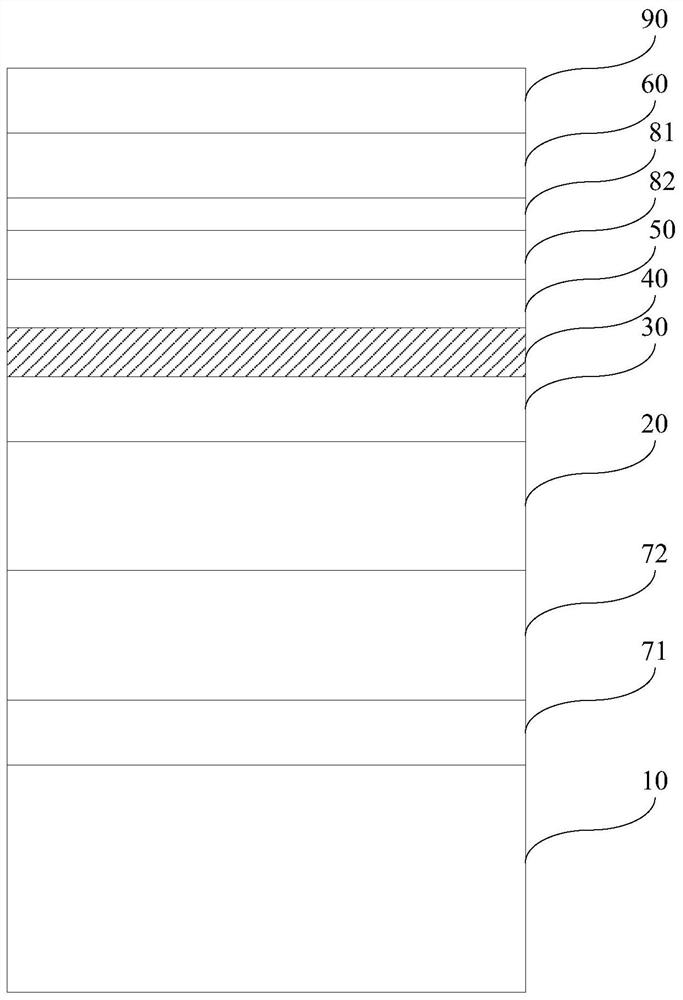

A gallium nitride-based light-emitting diode epitaxial wafer and its growth method

ActiveCN109065675BAffects radiative recombination luminescenceImprove luminous efficiencySemiconductor devicesIndiumGallium nitride

The invention discloses a gallium nitride-based light emitting diode epitaxial wafer and a growth method thereof, belonging to the field of semiconductor technology. The gallium nitride-based light emitting diode epitaxial wafer comprises a substrate, buffer layer, N-type layer, active layer, low temperature P-type layer, an electron barrier layer and a high temperature P-type layer, The buffer layer, the N-type layer, the active layer, the low-temperature P-type layer, the electron blocking layer and the high-temperature P-type layer are laminated on the substrate in turn, the material of thelow-temperature P-type layer adopts P-type doped aluminum gallium nitride, and the material of the electron blocking layer adopts P-type doped aluminum indium gallium nitrogen layer. By changing thematerial of the low-temperature P-type layer to P-type doped aluminum gallium nitride, The barrier height of the low temperature P-type layer is increased by using the higher barrier of the aluminum component, and the material of the electron barrier layer is changed into the P-type doped Al-In-Ga-N layer. The barrier height of the electron barrier layer is decreased by using the lower barrier ofthe indium component, and finally the luminescence efficiency of the LED is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

A method for preparing p-type algan/alingan electron blocking layer near-ultraviolet leds with doping concentration and al component stepwise change

ActiveCN106299038BImprove injection efficiencyImprove composite luminous efficiencySemiconductor devicesUltravioletElectron blocking layer

The invention provides a method for preparing a p-type AlGaN / AlInGaN electron blocking layer near ultraviolet LED with doping density and Al component in stepwise change. In an LED epitaxial structure, an electron blocking layer adopts a p-type Aly1Ga1-y1N / AlyInx1Ga1-x1N superlattice structure, and the Al component is reduced from 0.2 to 0.05 stepwisely with the increase of superlattice cycle number; Mg doping density increases stepwisely with the increase of superlattice cycle number, and corresponding hole concentration increases from 0.5*10<17> cm<3> to 2* 10<17> cm<3>; the thickness range of the AlGaN barrier layer is 2-5 nm; and the thickness of the GaN well layer is 2 nm-5 nm. Through the design of the novel ultraviolet LED electronic blocking layer structure, hole injection efficiency can be improved effectively, and electron-hole recombination luminescence efficiency is improved, and thus near ultraviolet LED luminescence efficiency is improved.

Owner:东莞市中晶半导体科技有限公司

An n-sic substrate algan-based vertical structure resonant cavity ultraviolet led chip and its preparation method

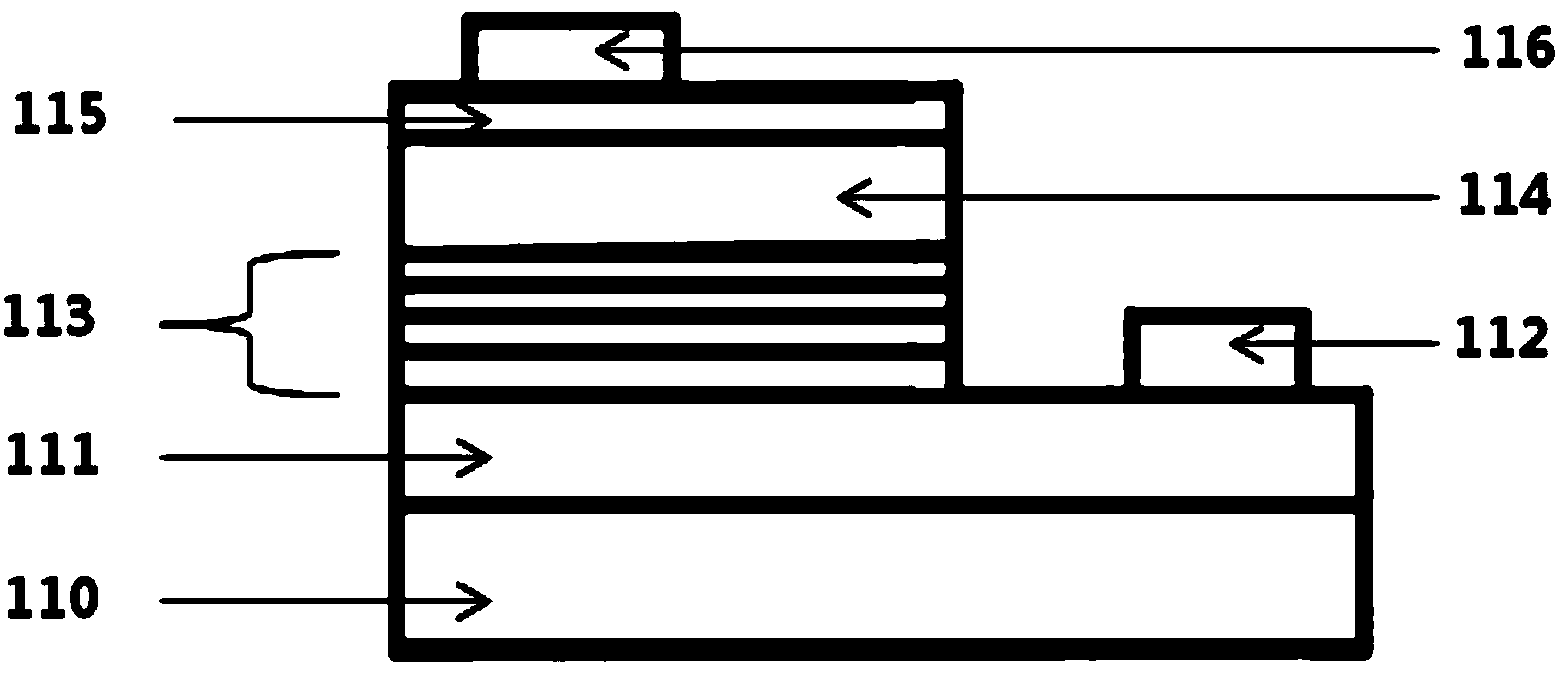

ActiveCN105957934BQuality improvementImprove composite luminous efficiencySemiconductor devicesUltraviolet lightsLight emitting device

The invention discloses an n-SiC substrate AlGaN group vertical structure resonant cavity ultraviolet LED chip and a production method thereof, and belongs to the semiconductor light-emitting device field. The n-SiC substrate AlGaN group vertical structure resonant cavity ultraviolet LED chip is respectively constituted by a lower electrode layer, an n-SiC substrate, an n-Alx0Gal-x0N conductive buffer layer, an n-AlGaN group DBR lower reflecting layer, an n-Alx1Ga1-x1N current expanding layer, an AlGaN base induced tunnel junction, a p-Alx2Gal-x2N hole injection layer, an AlGaN group quantum well active region, an n-Alx3Gal-x3N electron injection layer, an n-AlGaN group DBR upper reflecting layer, and an upper electrode layer, and in addition, x0, x1,x2,x3 are greater than or equal to 0.1, and smaller than or equal to 0.9. By adopting the SiC substrate, which is matched with the AlGaN lattice in a better way, the AlGaN quality is improved, and internal quantum efficiency is improved; by adopting the resonant cavity structure, TE mode polarized light is enhanced, and light extracting efficiency of a device is improved; structure inversion is realized by the tunnel junction, and influence of polarization electric field is reduced; composite light-emitting efficiency of charge carriers in the quantum well is improved. The application range of the semiconductor ultraviolet light-emitting device is further extended.

Owner:上海镓旦电子信息有限公司

A kind of epitaxial wafer of light-emitting diode and its manufacturing method

ActiveCN107331744BIncrease the number of holesAdd compound glowSemiconductor devicesNon dopedGallium nitride

The invention discloses an epitaxial wafer of a light-emitting diode and a manufacturing method thereof, belonging to the technical field of semiconductors. The epitaxial wafer includes a substrate and a buffer layer, an undoped gallium nitride layer, an N-type gallium nitride layer, a light-emitting layer and a P-type gallium nitride layer stacked sequentially on the substrate, and the light-emitting layer includes A plurality of quantum well layers and a plurality of quantum barrier layers, the plurality of quantum well layers and the plurality of quantum barrier layers are alternately stacked, the quantum barrier layer is a gallium nitride layer, and the plurality of quantum well layers The at least three quantum well layers closest to the N-type gallium nitride layer are the first quantum well layers, and the quantum wells in the plurality of quantum well layers except the first quantum well layer The second quantum well layer is a second quantum well layer, the first quantum well layer is an undoped InGaN layer, and the second quantum well layer includes a P-type doped InGaN layer. The invention increases the number of holes in the quantum well layer and improves the efficiency of compound light emission of holes and electrons.

Owner:HC SEMITEK CORP

A light-emitting diode epitaxial wafer and its manufacturing method

ActiveCN108281519BInhibit migrationBlocking aggregationSemiconductor devicesActivation energyQuantum well

The invention discloses a light-emitting diode epitaxial wafer and a manufacture method thereof and belongs to the technical field of semiconductors. The light-emitting diode epitaxial wafer comprisesan electronic barrier layer that includes superlattice structure of N cycles; the superlattice structure of each cycle includes an InxGa1-xN layer and an AlyG1-yN layer, wherein the InxGa1-xN layer is formed by growth at 900-950 DEG C; lattice quality of a multi-quantum well layer can be improved, composite light-emitting efficiency of electrons and holes in the multi-quantum well layer can be improved. In addition, the presence of In brings down activation energy of Mg and increases hole concentration of a P-type layer. Each AlyG1-yN layer is formed by growth at 950-980 DEG C, barrier heightof the AlyG1-yN layer is increased, and electrons are avoided overflowing to the P-type layer; the content of Al gradually decreases or increases, so that electrons can be avoided overflowing to theP-type layer at the premise of reducing the blocking action of holes, and light-emitting efficiency of a diode is improved.

Owner:HC SEMITEK SUZHOU

A gallium nitride-based light-emitting diode epitaxial wafer and its growth method

ActiveCN109860357BReduce injectionFacilitate horizontal expansionSemiconductor devicesDopantElectron hole

The invention discloses a gallium nitride-based light-emitting diode epitaxial wafer and a growth method thereof, belonging to the technical field of semiconductors. The gallium nitride-based light-emitting diode epitaxial wafer includes a substrate, an N-type semiconductor layer, a stress release layer, an active layer, and a P-type semiconductor layer, and the N-type semiconductor layer, the stress release layer, and the active layer and the P-type semiconductor layer are sequentially stacked on the substrate, and the gallium nitride-based light-emitting diode epitaxial wafer further includes an electronic adjustment layer, and the electronic adjustment layer is arranged on the stress release layer and the active layer Between; the material of the electronic adjustment layer is N-type doped aluminum gallium nitride, and the doping concentration of the N-type dopant in the electronic adjustment layer is along the stacking direction of the gallium nitride-based light-emitting diode epitaxial wafer slowing shrieking. The invention can improve the recombination luminous efficiency of electrons and holes in the active layer.

Owner:HC SEMITEK SUZHOU

A near-ultraviolet LED with a novel electron blocking layer and its preparation method

ActiveCN105932130BImprove injection efficiencyImprove composite luminous efficiencyMaterial nanotechnologySemiconductor devicesNon dopedContact layer

The invention provides a near-ultraviolet LED lamp with a novel electron blocking layer, and a preparation method thereof. A near-ultraviolet LED epitaxial wafer structure comprises a graphical sapphire substrate, a low-temperature GaN nucleating layer, a high-temperature non-doped GaN buffer layer, an n-type GaN layer, an InGaN / AlGaN multiple-quantum well active layer, a p-type AlGaN / InGaN superlattice electron blocking layer, a low-temperature lightly-doped p-type AlInGaN hole expansion layer, a high-temperature p-type GaN layer and a p-type InGaN contact layer. The electron blocking layer adopts a p-type Al<y1>Ga<1 y1>N / In<x1>Ga<1 x1>N superlattice structure. Along with the increase of the number of superlattice periods, the InGaN thickness is reduced step by step, the Mg doping concentration is increased step by step and the hole concentration is increased. By the invention, the hole injection efficiency is effectively improved and the electron hole recombination luminous efficiency is enhanced, so the near-ultraviolet LED luminous efficiency is increased.

Owner:东莞市中晶半导体科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com