A near-ultraviolet LED lamp with novel electron blocking layer, and preparation method thereof

An electron blocking layer and near-ultraviolet technology, which is applied in the direction of circuits, electrical components, nanotechnology for materials and surface science, etc., can solve the problem that the output power is only the input power, so as to improve the efficiency of hole injection and improve the efficiency of electron holes. Hole recombination luminous efficiency, the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

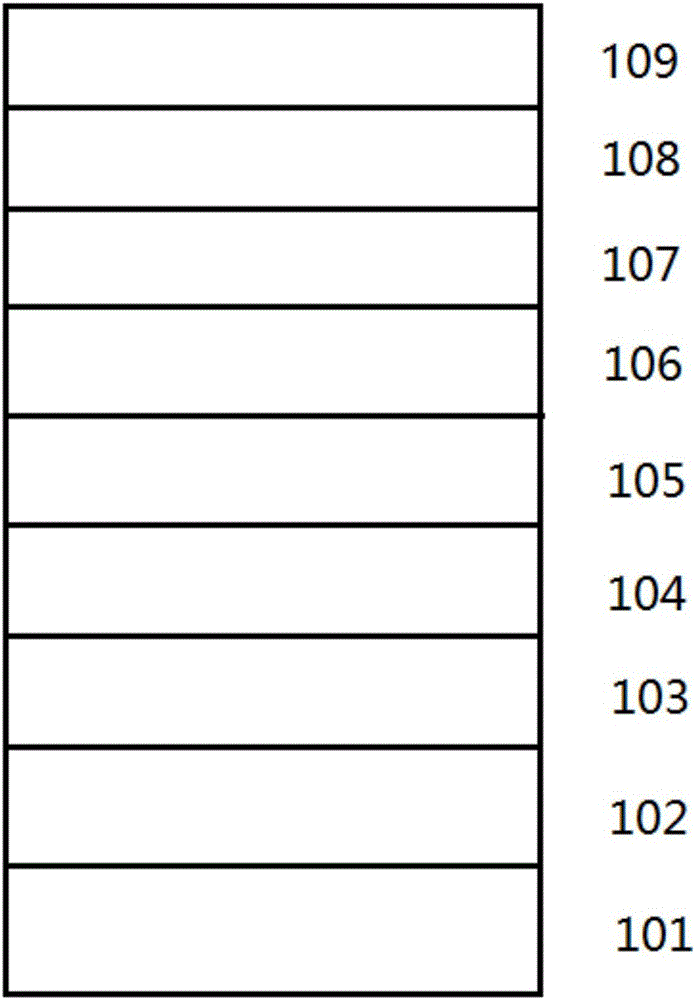

[0023] Using Aixtron’s close-coupled vertical reaction chamber MOCVD growth system, trimethylgallium (TMGa) or triethylgallium, trimethylaluminum, trimethylindium and ammonia were used as Ga, Al and In during the growth process. and N source, silane (SiH 4 ) as an n-type dopant source, dimagnesocene (Cp 2 Mg) as a p-type dopant source;

[0024] In the metal organic compound vapor phase epitaxy reaction chamber, the patterned sapphire substrate 101 will be heated in hydrogen (H 2 ) atmosphere, 1080°C-1100°C, reaction chamber pressure 100torr, treatment for 5-15 minutes; then lower the temperature, at 500-550°C, reaction chamber pressure 600torr, H 2 Under the atmosphere, the V / III molar ratio is 100-1500; three-dimensionally grow a 20 nm-thick low-temperature GaN nucleation layer 102;

[0025] At 1000-1100°C, the reaction chamber pressure is 200-300torr, H 2 Under the atmosphere, the V / III molar ratio is 1000-1300; grow a high-temperature non-doped GaN buffer layer 103 with...

Embodiment 2

[0034] Using Aixtron’s close-coupled vertical reaction chamber MOCVD growth system, trimethylgallium (TMGa) or triethylgallium, trimethylaluminum, trimethylindium and ammonia were used as Ga, Al and In during the growth process. and N source, silane (SiH 4 ) as an n-type dopant source, dimagnesocene (Cp 2 Mg) as a p-type dopant source;

[0035] In the metal organic compound vapor phase epitaxy reaction chamber, the patterned sapphire substrate 101 will be 2 ) atmosphere, 1080°C-1100°C, reaction chamber pressure 100torr, treatment for 5-15 minutes; then lower the temperature, at 500-550°C, reaction chamber pressure 600torr, H 2 Under the atmosphere, the V / III molar ratio is 100-1500; three-dimensionally growing a 30 nm-thick low-temperature GaN nucleation layer 102;

[0036] At 1000-1100°C, the reaction chamber pressure is 200-300torr, H 2 Under the atmosphere, the V / III molar ratio is 1000-1300; grow a high-temperature non-doped GaN buffer layer 103 with a thickness of 2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com