OLED device

A technology of devices and nanomaterials, applied in the field of QLED devices, can solve problems such as high lighting voltage, device luminescence quenching, and poor stability, and achieve the effects of reducing driving voltage, reducing quenching, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

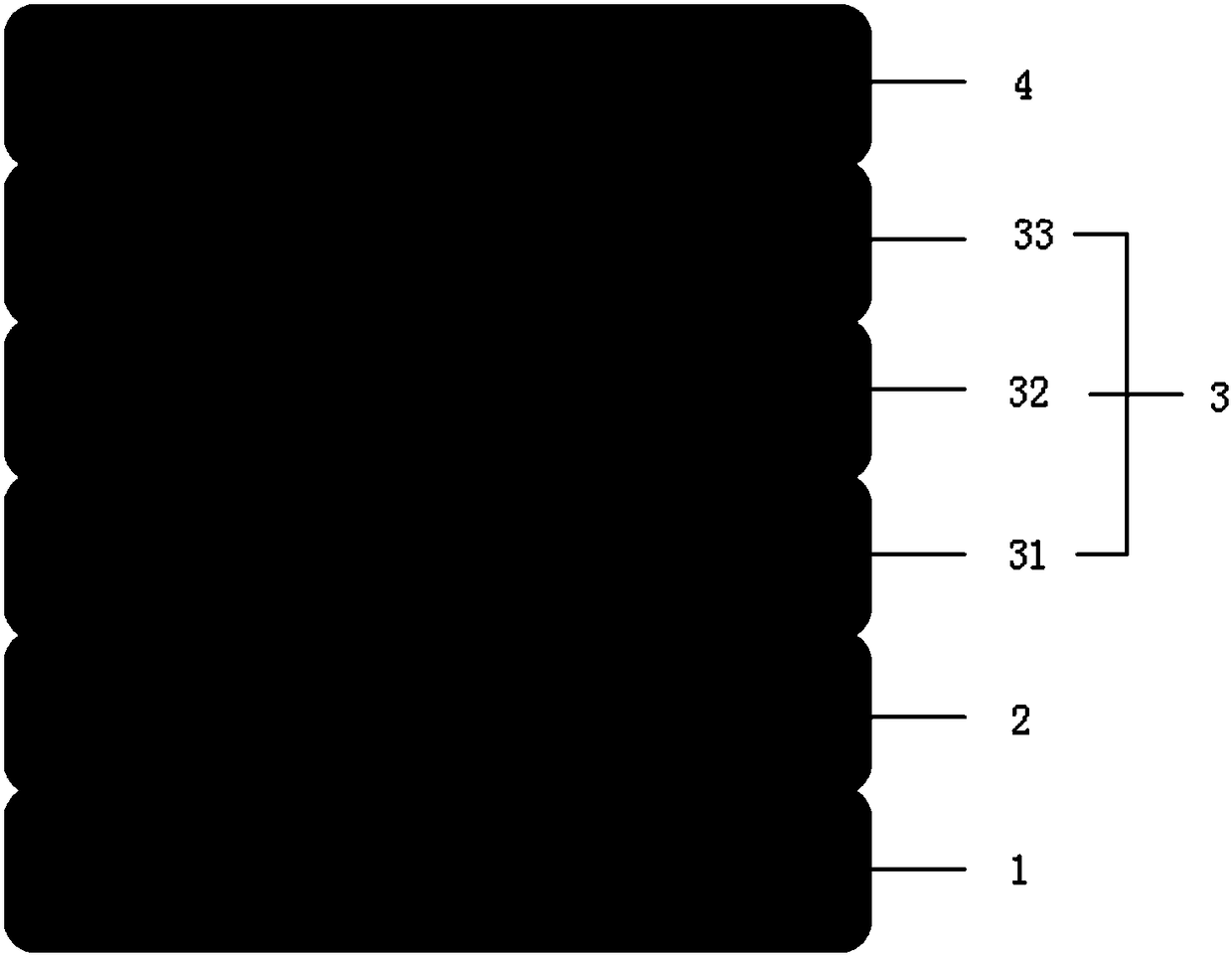

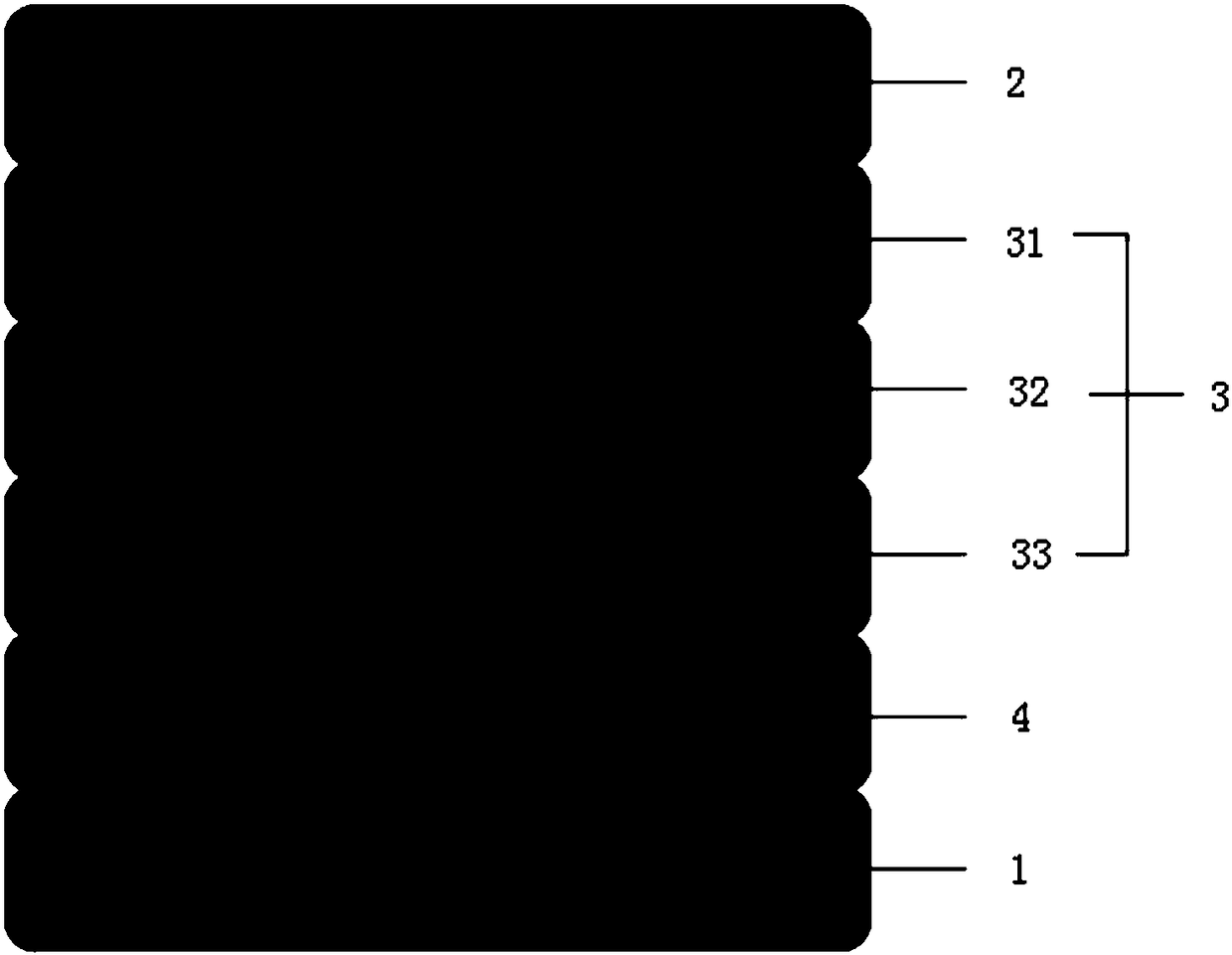

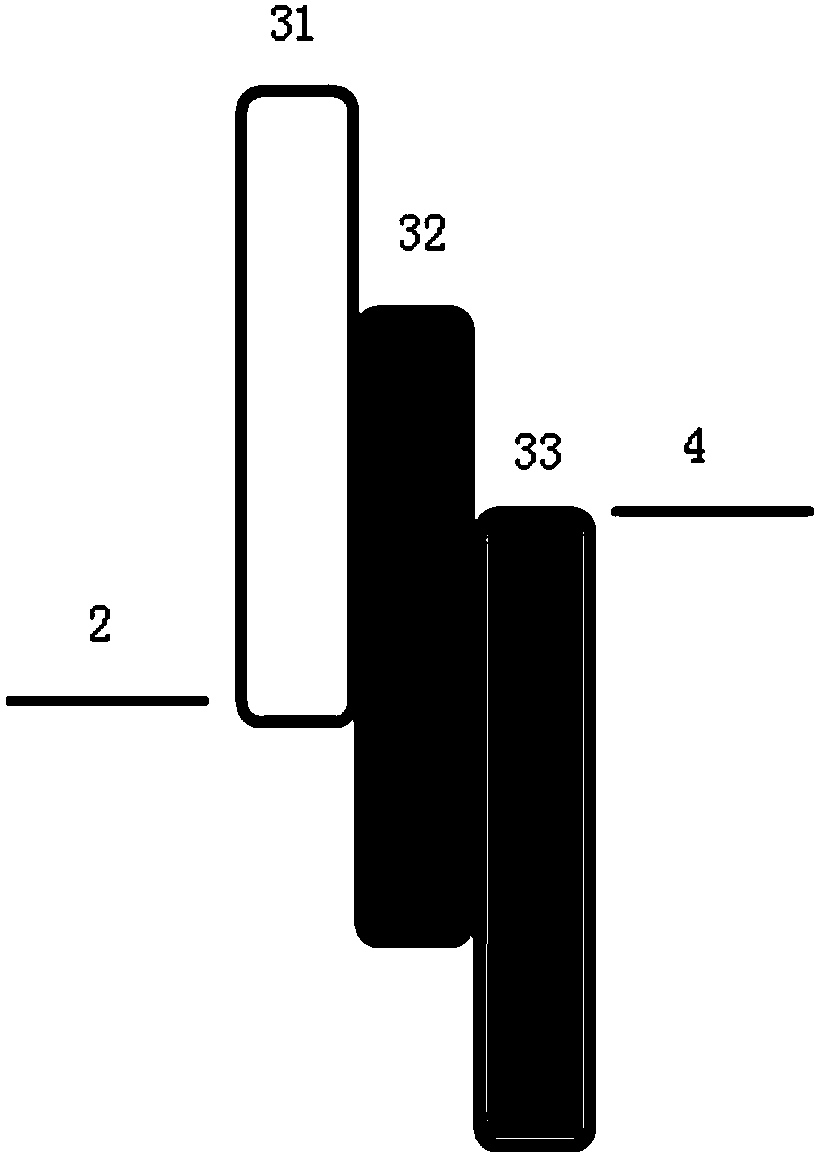

[0038] A QLED device, comprising a bottom electrode, a bipolar Auger energy multiplication structure and a top electrode sequentially stacked on a glass substrate, the bipolar Auger energy multiplication structure is a sequentially combined hole transport layer, quantum dot light emitting Layer and electron transport layer, wherein, the substrate is a glass substrate, the anode is 120nm ITO, the electron transport layer is nickel oxide with a size of 5nm and a thickness of 25nm, and the quantum dot light-emitting layer is 40nm CdSe / ZnS (luminescence wavelength 530 nm, quantum yield 90%), the hole transport layer is zinc oxide with a size of 3 nm and a thickness of 20 nm, and the cathode is Al.

Embodiment 2

[0040] A QLED device, comprising a bottom electrode, a bipolar Auger energy multiplication structure and a top electrode sequentially stacked on a glass substrate, the bipolar Auger energy multiplication structure is a sequentially combined hole transport layer, quantum dot light emitting Layer and electron transport layer, wherein, the substrate is a glass substrate, the anode is 120nm ITO, the electron transport layer is copper-doped nano-molybdenum oxide with a thickness of 50nm, and the doped nano-molybdenum oxide The size is 10nm, the doping weight percentage of copper is 10%, the quantum dot light-emitting layer is 40nm CdSe / ZnS (luminescence wavelength 632 nanometers, quantum yield 85%), and the hole transport layer is It is 20nm lithium-doped nano-zinc oxide, and the size of the doped nano-zinc oxide is 3nm, the doping weight percentage of lithium is 5%, and the cathode is Al.

Embodiment 3

[0042] A QLED device, comprising a bottom electrode, a bipolar Auger energy multiplication structure and a top electrode sequentially stacked on a glass substrate, the bipolar Auger energy multiplication structure is a sequentially combined hole transport layer, quantum dot light emitting Layer and electron transport layer, wherein, the substrate is a glass substrate, the anode is 120nm ITO, the electron transport layer is copper-doped nano-molybdenum oxide with a thickness of 30nm, and the doped nano-molybdenum oxide The size is 5nm, the doping weight percentage of copper is 10%, the quantum dot light-emitting layer is 40nm CdSe / ZnS (light-emitting wavelength 530 nanometers, quantum yield 90%), and the hole transport layer is It is 20nm aluminum-doped nano-zinc oxide, and the size of the doped nano-zinc oxide is 3nm, the doping weight percentage of lithium is 5%, and the cathode is Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mobility | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com