A kind of high-brightness light-emitting diode based on Aln/PSS composite substrate and preparation method thereof

A technology of light-emitting diodes and composite substrates, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as high brightness and insufficient brightness, and achieve the effects of high brightness, improved current expansion, and improved luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

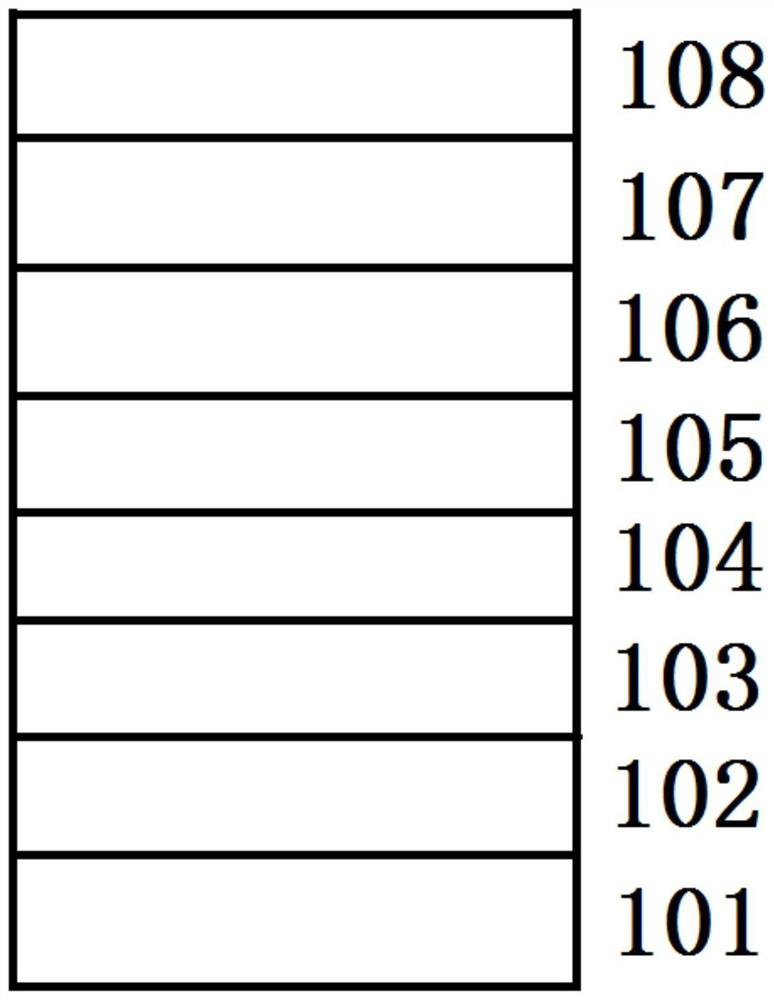

[0037] A high-brightness light-emitting diode based on AlN / PSS composite substrate, such as figure 1As shown, it includes an AlN / PSS composite substrate 101, a u-type GaN merged layer 102, an n-type GaN layer 103, a low-temperature GaN V-pits layer 104, an active region 105, and an electron blocking layer 106 stacked sequentially from bottom to top. , a high temperature p-type GaN layer 107 and a contact layer 108 .

[0038] The high-brightness light-emitting diode is prepared through the following preparation steps:

[0039] S1. In a mixed atmosphere of hydrogen and ammonia, at a temperature of 950-1000° C., perform surface activation treatment on the AlN / PSS composite substrate; the reaction chamber pressure is 100 torr, and the treatment is performed for 5-10 minutes.

[0040] S2. Introducing ammonia gas, growing a u-type GaN merged layer on the AlN / PSS composite substrate (101);

[0041] The u-type GaN merged layer includes the first u-type GaN layer, the second u-type G...

Embodiment 2

[0054] This embodiment is the second embodiment of the high-brightness light-emitting diode based on the AlN / PSS composite substrate of the present invention, such as figure 1 As shown, it includes an AlN / PSS composite substrate 101, a u-type GaN merged layer 102, an n-type GaN layer 103, a low-temperature GaN V-pits layer 104, an active region 105, and an electron blocking layer 106 stacked sequentially from bottom to top. , a high temperature p-type GaN layer 107 and a contact layer 108 .

[0055] The high-brightness light-emitting diode is prepared through the following preparation steps:

[0056] S1. In a mixed atmosphere of hydrogen and ammonia, at a temperature of 950-1000° C., perform surface activation treatment on the AlN / PSS composite substrate; the reaction chamber pressure is 100 torr, and the treatment is performed for 5-10 minutes.

[0057] S2. Introducing ammonia gas, growing a u-type GaN merged layer on the AlN / PSS composite substrate (101);

[0058] The u-ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com