UV light emitting diode with compound electronic barrier layer structure

An electron blocking layer, light-emitting diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low conductivity and low Mg activation efficiency, improve injection efficiency, prevent electrons from overflowing the active area, and improve luminescence. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

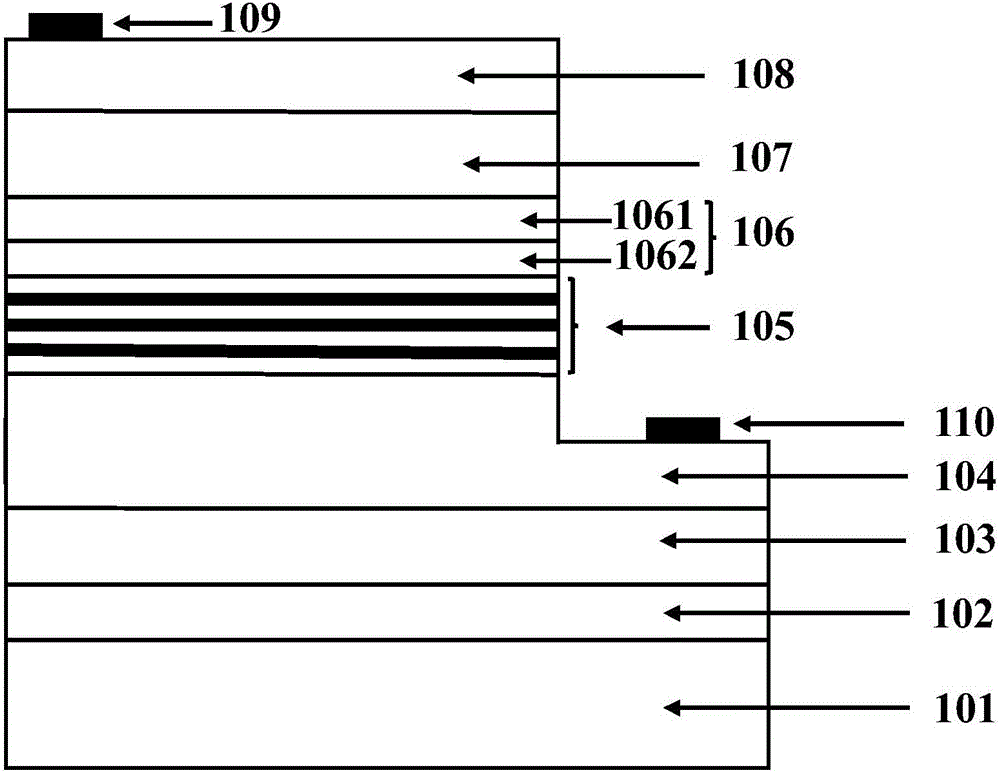

[0031] like figure 1 As shown, it is a UV-LED with a composite electron blocking layer structure provided by the present invention, including a substrate 101, a low-temperature AlN nucleation layer 102, a high-temperature AlN buffer layer 103, and an n-type AlGaN layer arranged in sequence from bottom to top 104.Al x Ga 1-x N / Al y Ga 1-y N multi-quantum well active region 105, made of p-Al s In t Ga 1-s-t N layer 1061 and p-Al z Ga 1-z N layer 1062 composed of p-Al s In t Ga 1-s-t N / p-Al z Ga 1-z N composite electron blocking layer 106, wherein z>y>x, 0≤s, t≤1, p-type AlGaN layer 107, p-type GaN ohmic contact layer 108, p-type ohmic contact layer 108 drawn on p-type GaN ohmic contact layer The electrode 109 is an n-type ohmic electrode 110 drawn out on the n-type AlGaN layer 104 .

[0032] The substrate 101 is r-plane 11-22 sapphire.

[0033] The n-type region 104 is an n-AlGaN epitaxial layer with a thickness of 1.5 μm, the n-type doping is doped with Si eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com