Transverse zinc oxide nanorod array light emitting diode

A zinc oxide nanorod, light-emitting diode technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low electron injection efficiency, reduction of effective light emitting area, and reduced light extraction efficiency, etc. , to achieve the effects of good electron confinement, good light transmittance, and good carrier conduction diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

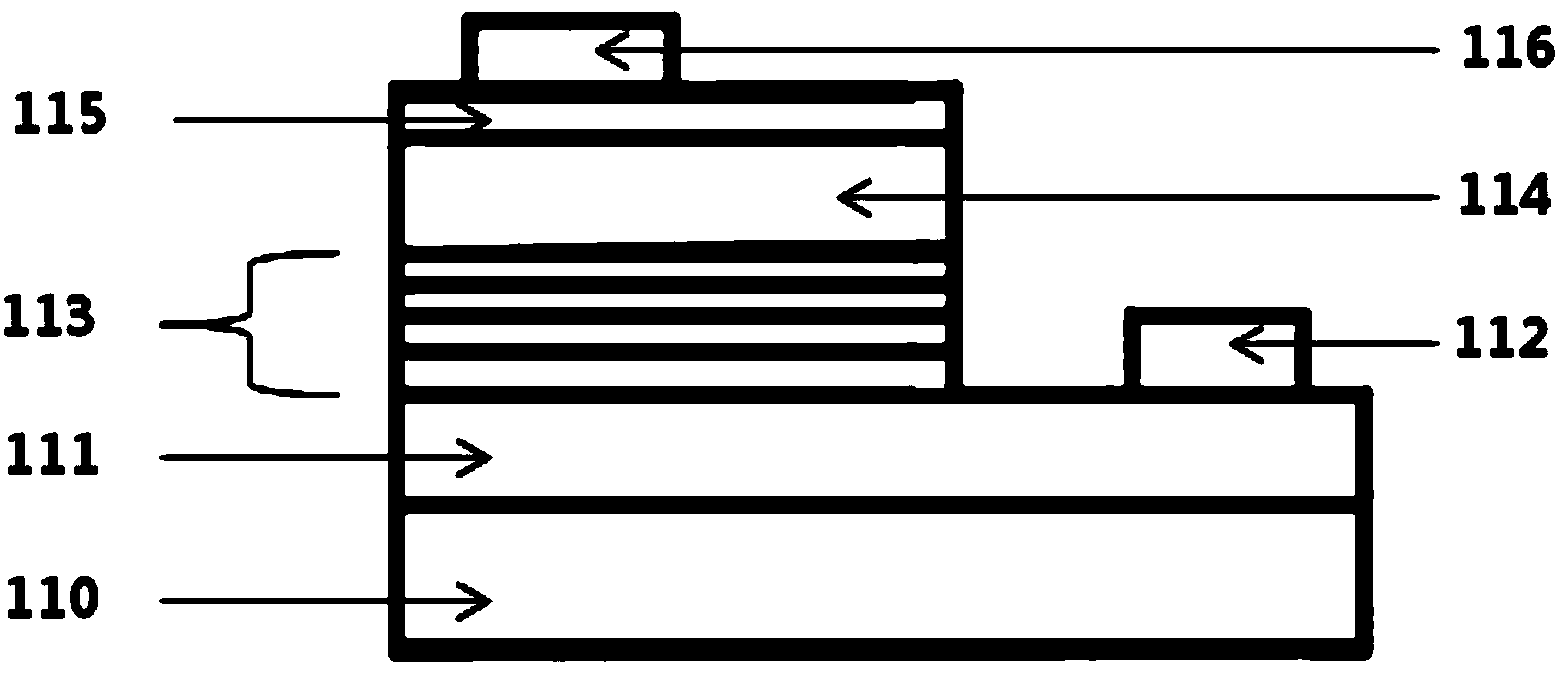

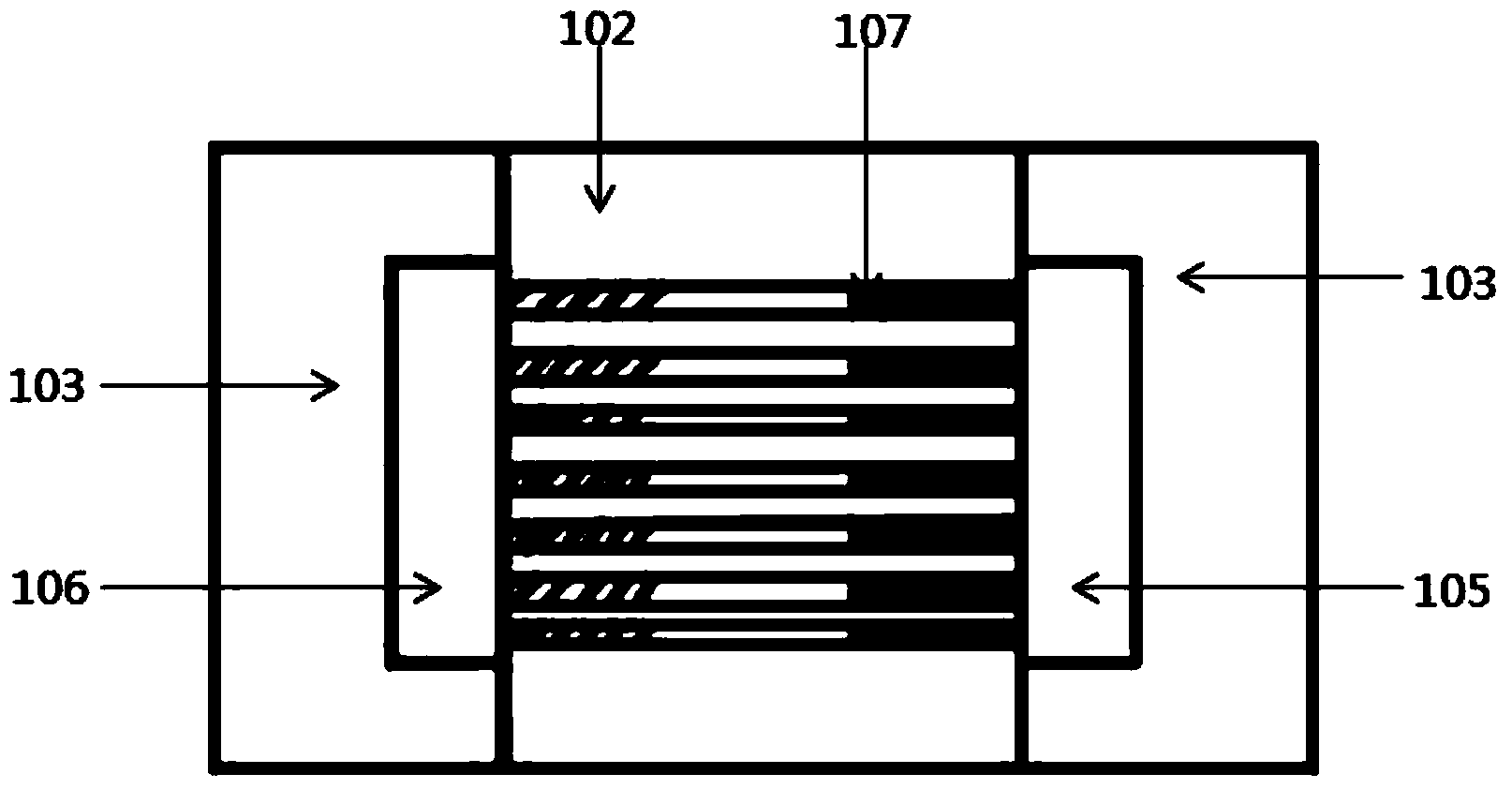

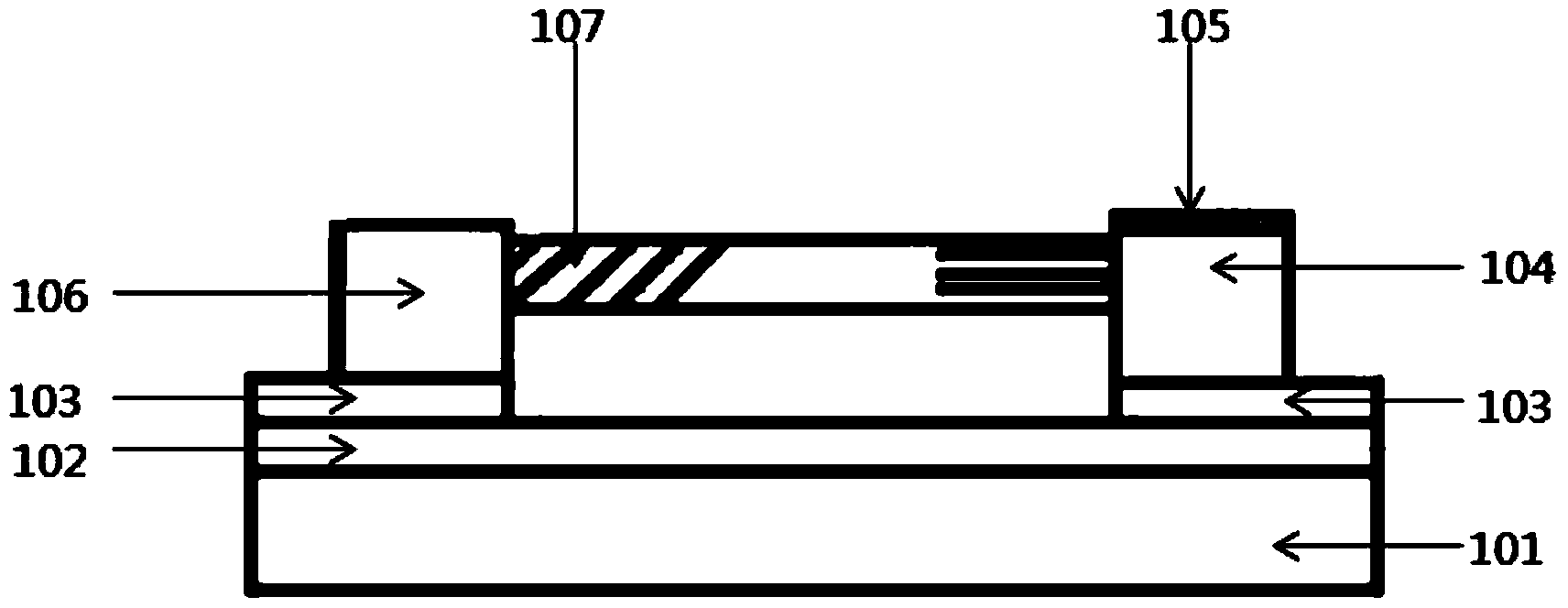

[0035] An LED with a lateral ZnO nanorod array structure, its constituent elements include: a sapphire substrate (101), a silicon dioxide insulating layer (102), a gallium nitride buffer layer (103), a p-region electrode (106), a block state n + -ZnO(104), p-region electrodes and bulk n + Nanorod arrays between -ZnO (107), n + - ITO-ZnO film (105) on ZnO as n-region electrode.

[0036] Among them, ZnO nanorods are obtained by high-temperature thermal evaporation method, and then prepared at equal intervals by p-region electrodes and n + Between the two platforms constructed by -ZnO, the two ends of the nanorods are trimmed into regular shapes by using the focused ion beam method.

[0037] ZnO material has a wide band gap and high exciton binding energy, and has good chemical stability, oxidation resistance, moisture resistance, and high temperature resistance, and is suitable for making ultraviolet and blue LEDs. By adjusting the block n + -The Ga doping amount of ZnO and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com