Epitaxial wafer for light-emitting diode, and manufacturing method for epitaxial wafer

A manufacturing method and technology for light-emitting diodes, which are applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low electron recombination luminescence efficiency, and achieve the effects of improving internal quantum efficiency, increasing recombination luminescence, and increasing the number of holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

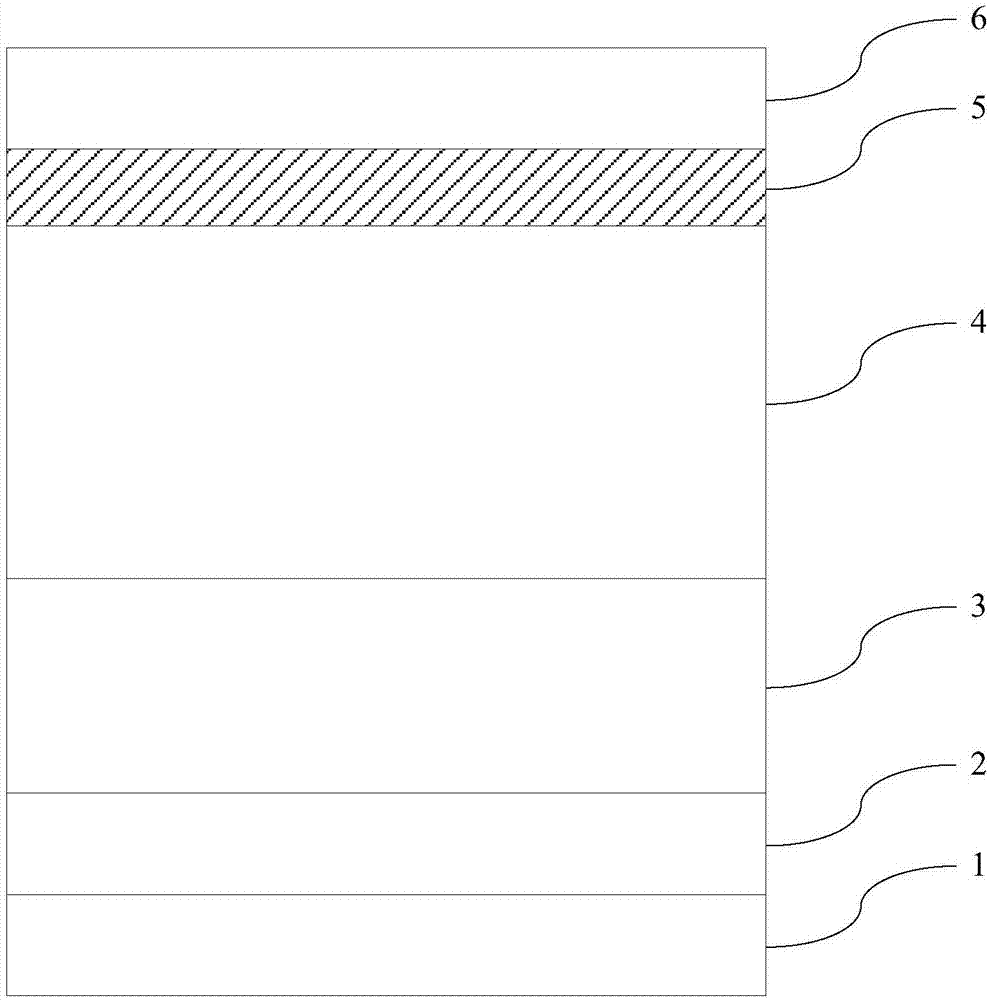

[0029] An embodiment of the present invention provides an epitaxial wafer of a light-emitting diode, see figure 1 The epitaxial wafer includes a substrate 1 and a buffer layer 2 , an undoped gallium nitride layer 3 , an N-type gallium nitride layer 4 , a light emitting layer 5 and a P-type gallium nitride layer 6 stacked on the substrate 1 in sequence.

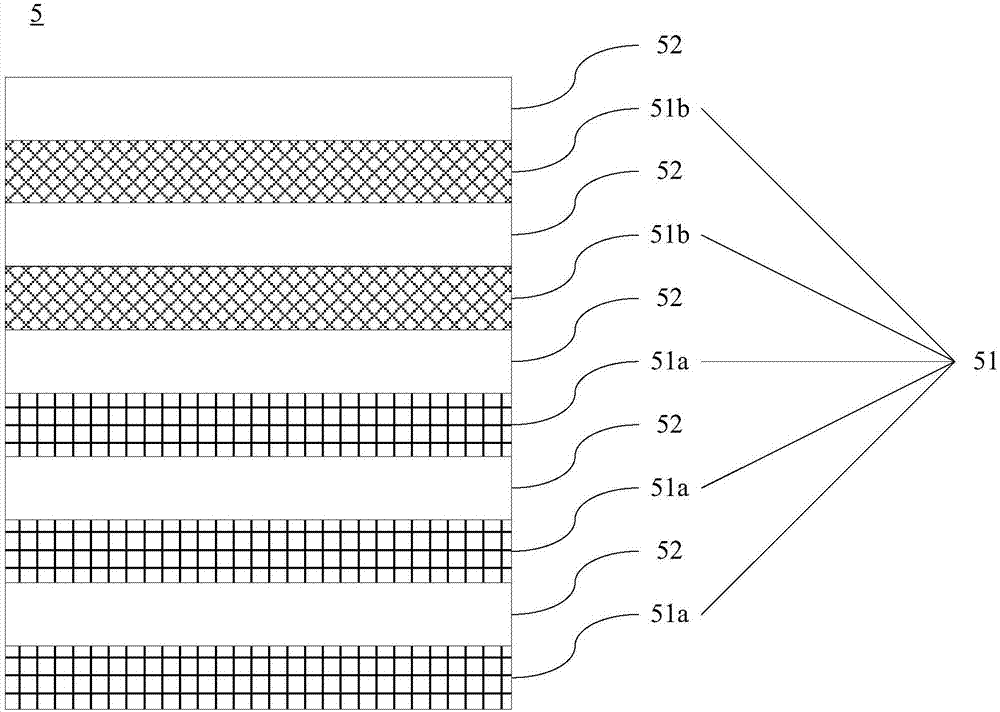

[0030] In this example, see figure 2 The light-emitting layer 5 includes multiple quantum well layers 51 and multiple quantum barrier layers 52, the multiple quantum well layers 51 and multiple quantum barrier layers 52 are alternately stacked, and the quantum barrier layers 52 are gallium nitride layers. Among the plurality of quantum well layers 51, at least three quantum well layers 51 closest to the N-type gallium nitride layer 4 are the first quantum well layer 51a, and among the plurality of quantum well layers 51, all but the first quantum well layer 51a The quantum well layer 51 is a second quantum well layer 51b, th...

Embodiment 2

[0054] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode, and the epitaxial wafer provided in this embodiment is a specific implementation manner of the epitaxial wafer provided in Embodiment 1.

[0055] In this embodiment, the number of layers of the first quantum well layer is 3, the number of layers of the second quantum well layer is 6, and the doping concentration of the P-type dopant in each second quantum well layer remains unchanged, and The doping concentrations of the P-type dopants in the multiple second quantum well layers are equal.

Embodiment 3

[0057] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode, and the epitaxial wafer provided in this embodiment is another specific implementation manner of the epitaxial wafer provided in Embodiment 1.

[0058] In this embodiment, the number of layers of the first quantum well layer is 3, the number of layers of the second quantum well layer is 6, and each second quantum well layer includes the first sublayer, the second sublayer and the second sublayer stacked in sequence. Three sublayers, the second sublayer is a P-type doped indium gallium nitride layer, the first sublayer and the third sublayer are undoped indium gallium nitride layers, the thickness of the first sublayer and the thickness of the third sublayer The thicknesses are equal, the thickness of the second sub-layer is 1nm, and the doping concentration of the P-type dopant in the plurality of second quantum well layers is equal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com