An n-sic substrate algan-based vertical structure resonant cavity ultraviolet led chip and its preparation method

An LED chip, vertical structure technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of low luminous efficiency of ultraviolet LEDs, and achieve the effects of improving luminous efficiency, reducing the influence of polarized electric fields, and avoiding current congestion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

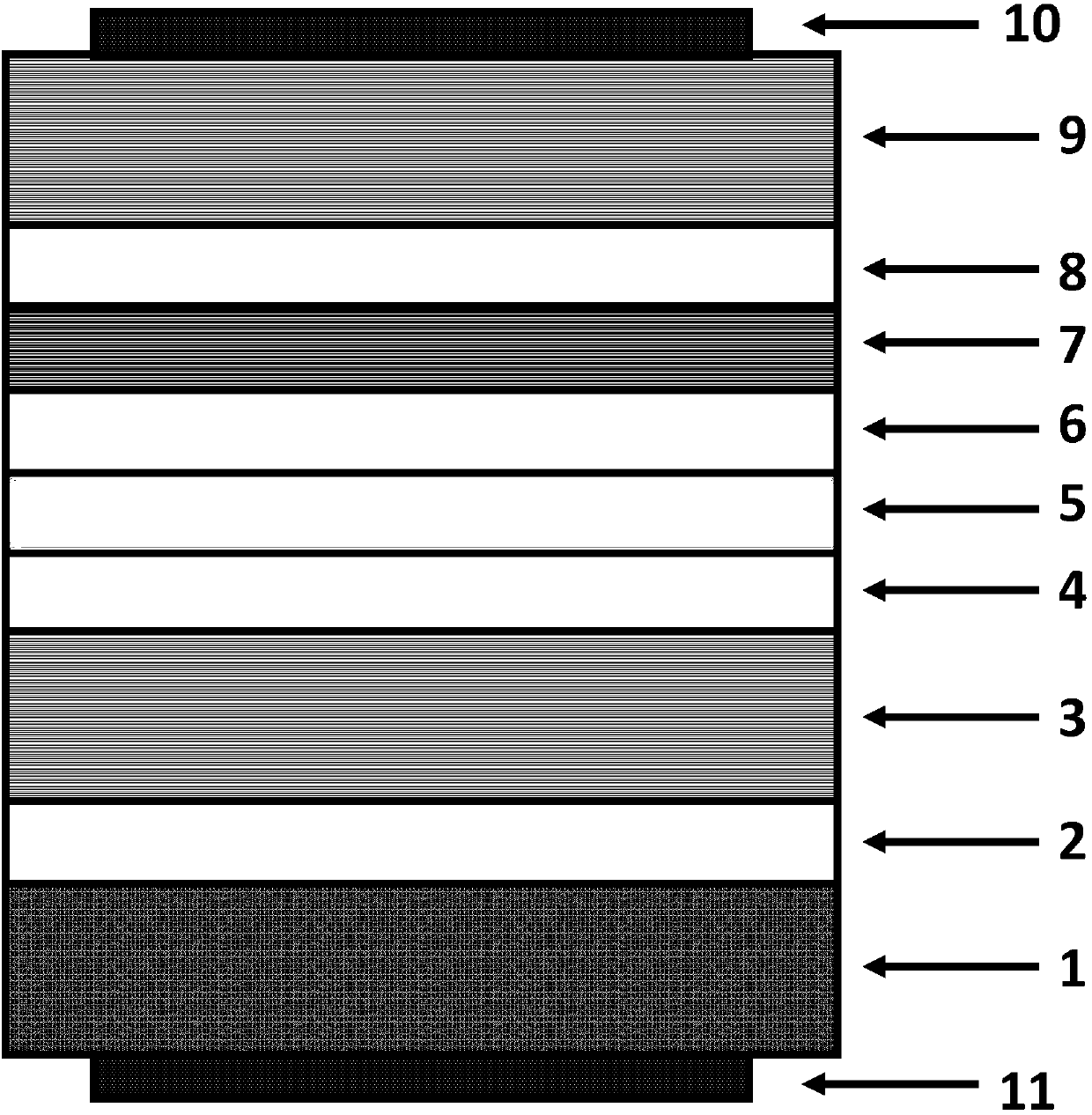

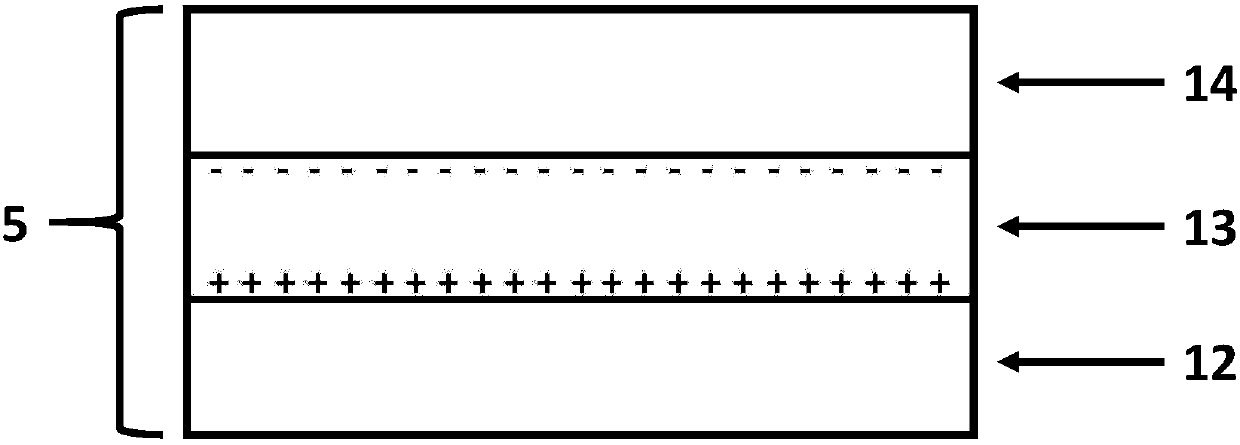

[0020] 1. Using MOCVD method, one-time epitaxial preparation of AlGaN-based ultraviolet LED structure on commercial n-SiC substrate, such as figure 1 shown. The specific structure is as follows: in n-SiC (the doping concentration is 2×10 18 / cm 3 ) on the substrate 1 sequentially prepare n-Al 0.3 Ga 0.7 N conductive buffer layer 2 (thickness 80nm), n-AlGaN base DBR lower reflection layer 3 (by 34nm thick n-Al 0.1 Ga 0.9 N layer and 36nm thick n-Al 0.3 Ga 0.7 N layer alternate growth composition, the doping concentration is 2×10 18 / cm 3 and 4×10 18 / cm 3 , the logarithm is 30, the reflectivity is 95%), n-Al 0.1 Ga 0.9 N-layer current spreading layer 4 (doping concentration 5×10 17 / cm 3 , thickness 200nm), AlGaN-based polarization-induced tunnel junction 5 (Al 0.3 Ga 0.7 N polarization inducing layer 13 has a thickness of 10nm, and this layer is not doped; n-Al 0.1 Ga 0.9 N layer 12 and p-Al 0.1 Ga 0.9 The N layer 14 has a thickness of 100nm and a doping co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com