Construction of 3D printing device for producing components

A kind of equipment, 3D technology, applied in the direction of 3D object support structure, processing and manufacturing, manufacturing tools, etc., can solve problems such as damaged construction area, unusable molded parts, damaged molded parts, etc., to achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Preferred embodiments are shown in the accompanying drawings:

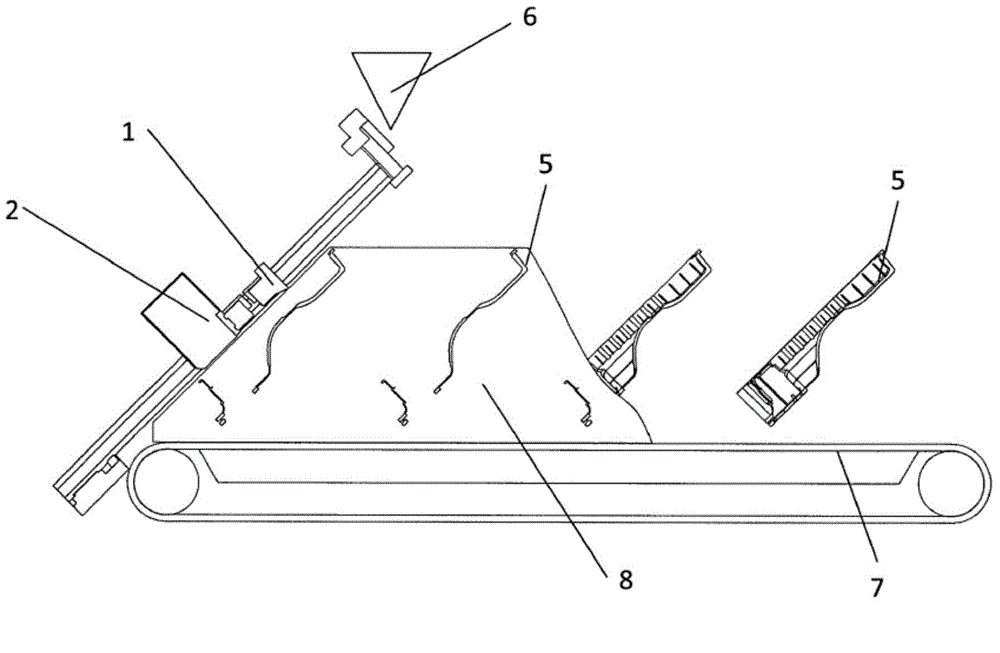

[0070] figure 1 The functional principle of the continuous 3D printing process is shown. The left side shows the front side of the machine, including the build area on which components are manufactured layer by layer. Coating of the individual layers is carried out at angles smaller than the specific angle of repose of the particulate material being treated. The conveyor belt (7) moves the feed material (8) to the right to the rear side of the machine. Finished parts can be removed here.

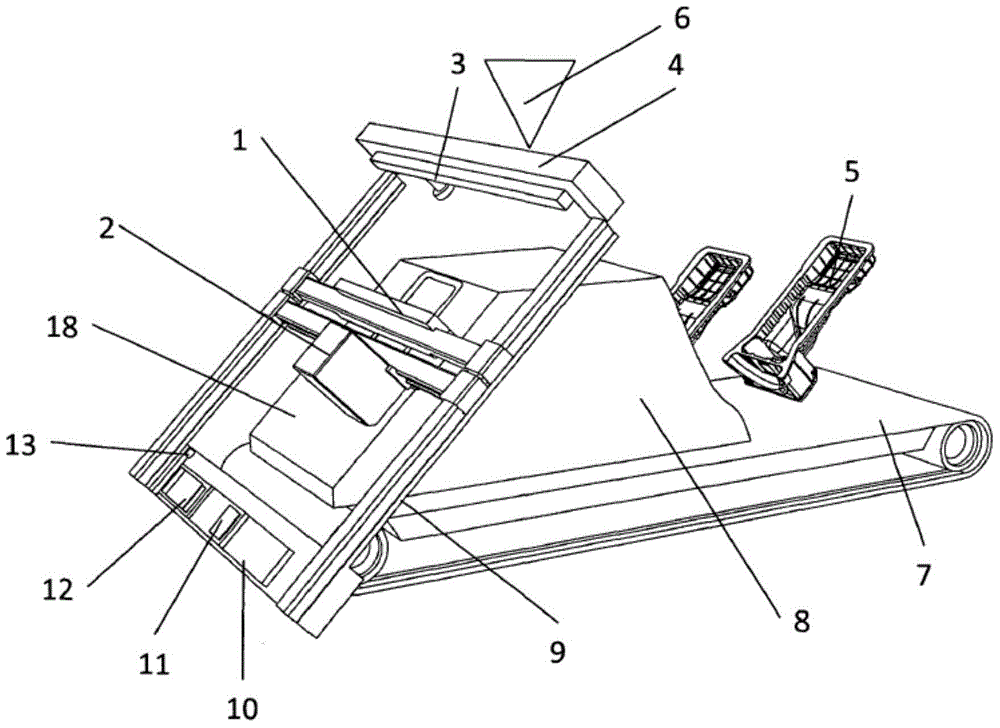

[0071] figure 2 A preferred structure of the invention is shown. Axis systems (9) for positioning the print heads are arranged on the left and right of the build area (18) on the front side of the machine. The applicator filling unit (4) and applicator cleaning unit (3) are located on top behind the build area. Excess particulate material from cleaning or filling operations of the applicator falls on the feed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com