Battery separator

By stacking a modified porous layer on a polyolefin microporous membrane and using materials such as polyethylene resin and fluororesin, the problem of insufficient thermal shrinkage resistance of battery separators within a temperature range has been solved, and the electrode adhesion and separator properties have been improved. overall performance, reducing the risk of short circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] (1) Preparation process of polyolefin resin solution

[0065] The polyolefin resin solution is prepared by melt-kneading after adding a suitable film-forming solvent to the polyolefin resin. Various additives such as the above-mentioned inorganic fillers, antioxidants, ultraviolet absorbers, anti-blocking agents, pigments, and dyes can be added to the polyolefin resin solution as necessary within a range that does not impair the effects of the present invention. For example, micronized silicic acid can be added as a pore former.

[0066] As the film-forming solvent, either a liquid solvent or a solid solvent can be used. Examples of the liquid solvent include aliphatic or cyclic hydrocarbons such as nonane, decane, decalin, p-xylene, undecane, dodecane, and liquid paraffin, and mineral oil fractions having boiling points corresponding to these. In order to obtain a gel-like sheet having a stable solvent content, it is preferable to use a nonvolatile liquid solvent suc...

Embodiment 1

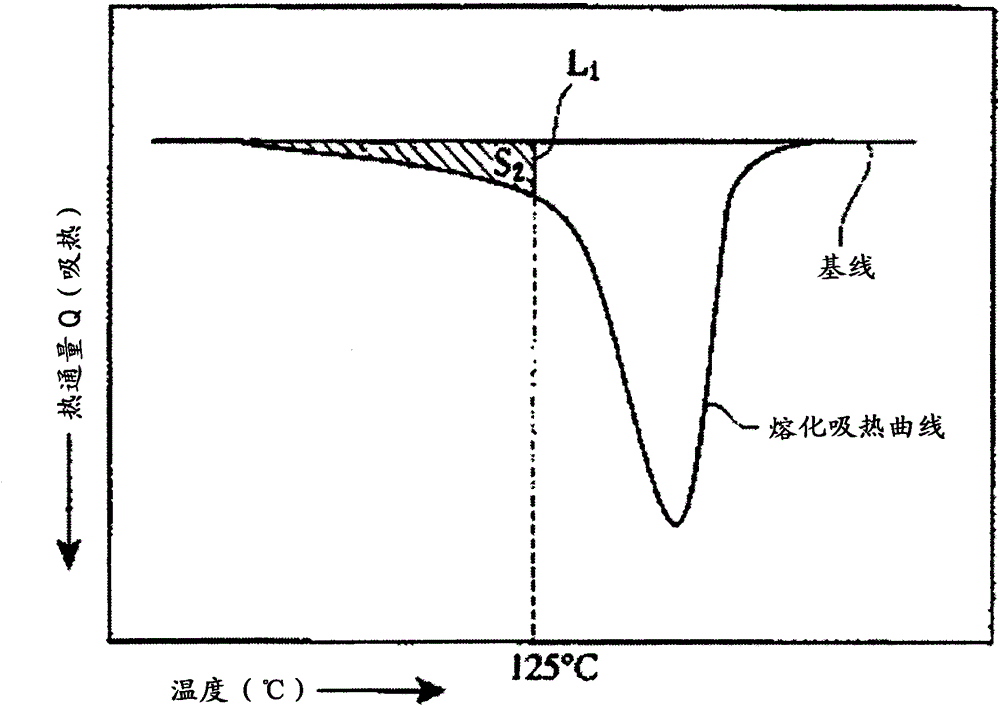

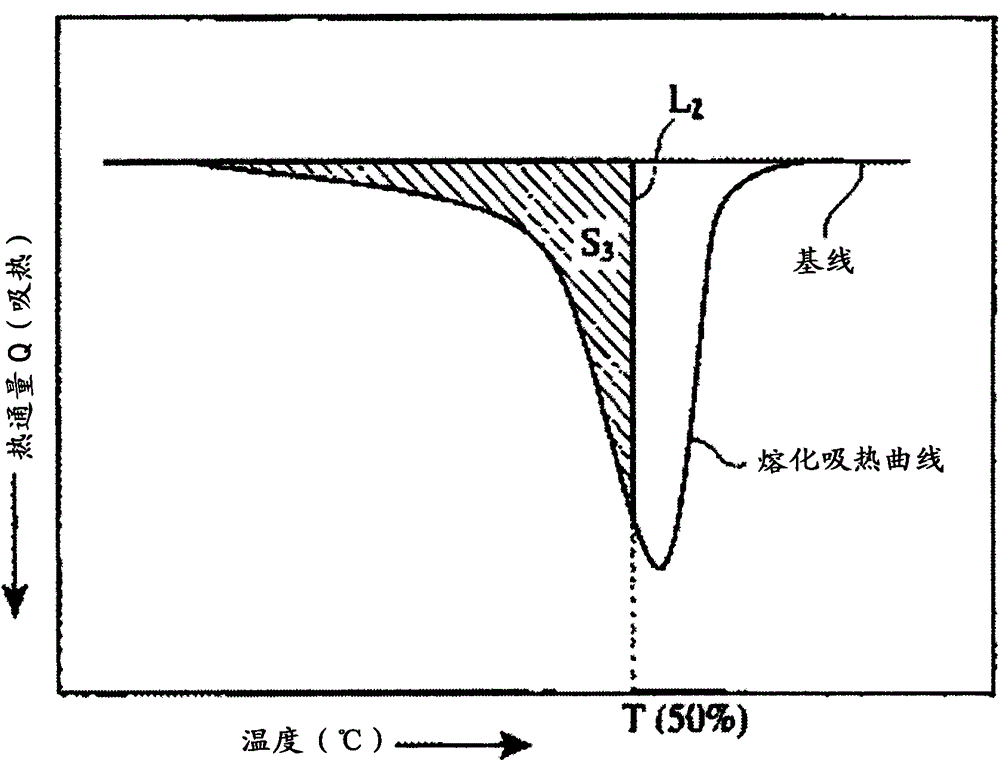

[0193] The mass average molecular weight (Mw) is 2.5×10 6 of ultra-high molecular weight polyethylene (UHMwPE) 30% by mass and Mw of 3.0×10 5 100 parts by mass of a polyethylene (PE) composition composed of 70 mass % of high-density polyethylene (HDPE) is dry mixed with tetrakis[methylene-3-(3,5-di-tert-butyl-4-hydroxyphenyl] )-propionate]methane 0.375 parts by mass. For the PE composition composed of UHMWPE and HDPE, the measured ΔHm (≤125°C) was 14%, T (50%) was 132.5°C, melting point was 135°C, and crystal dispersion temperature was 100°C.

[0194] The Mw of UHMwPE and HDPE was obtained by gel permeation chromatography (GPC) method under the following conditions (the same below).

[0195] Measurement device: GPC-150C manufactured by Waters Corporation

[0196] Column: Shodex UT806M manufactured by Showa Denko Co., Ltd.

[0197] ·Column temperature: 135℃

[0198] Solvent (mobile phase): o-dichlorobenzene

[0199] Solvent flow rate: 1.0mL / min

[0200] ·Sample concentra...

Embodiment 2

[0211] In the film formation of the polyethylene microporous film of Example 1, the polyethylene composition was adjusted while maintaining the ratio of the input amount of the polyethylene composition to the screw rotation speed Ns at Q / Ns=0.3 kg / h / rpm. The input amount of the material and the rotational speed of the screw were used to prepare a polyethylene microporous membrane (b) with a thickness of 9 μm and an airtightness of 70 sec / 100 ccAir. Next, a modified porous layer was laminated on one side of the polyethylene microporous membrane (b) by the same method as in Example 1, to obtain a battery separator having a final thickness of 11 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat of fusion | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| linear shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com