Chemical regulator for improving grain filling plumpness of rice, and preparation method and use method thereof

A technology for rice grains and regulators, which is applied in the fields of botanical equipment and methods, plant growth regulators, plant growth regulators, etc., can solve the problems of low grain storage activity, poor grain filling, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

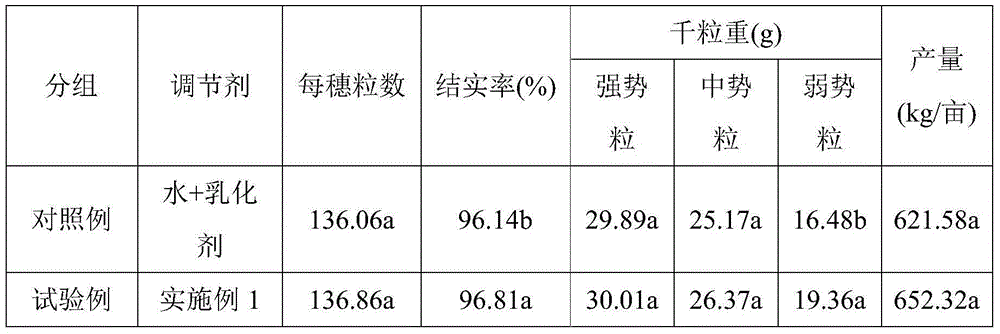

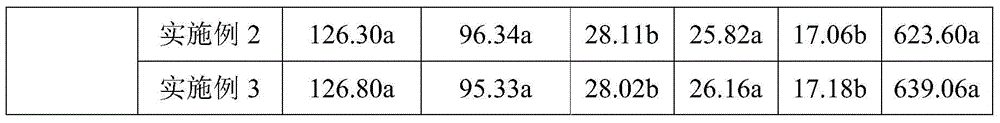

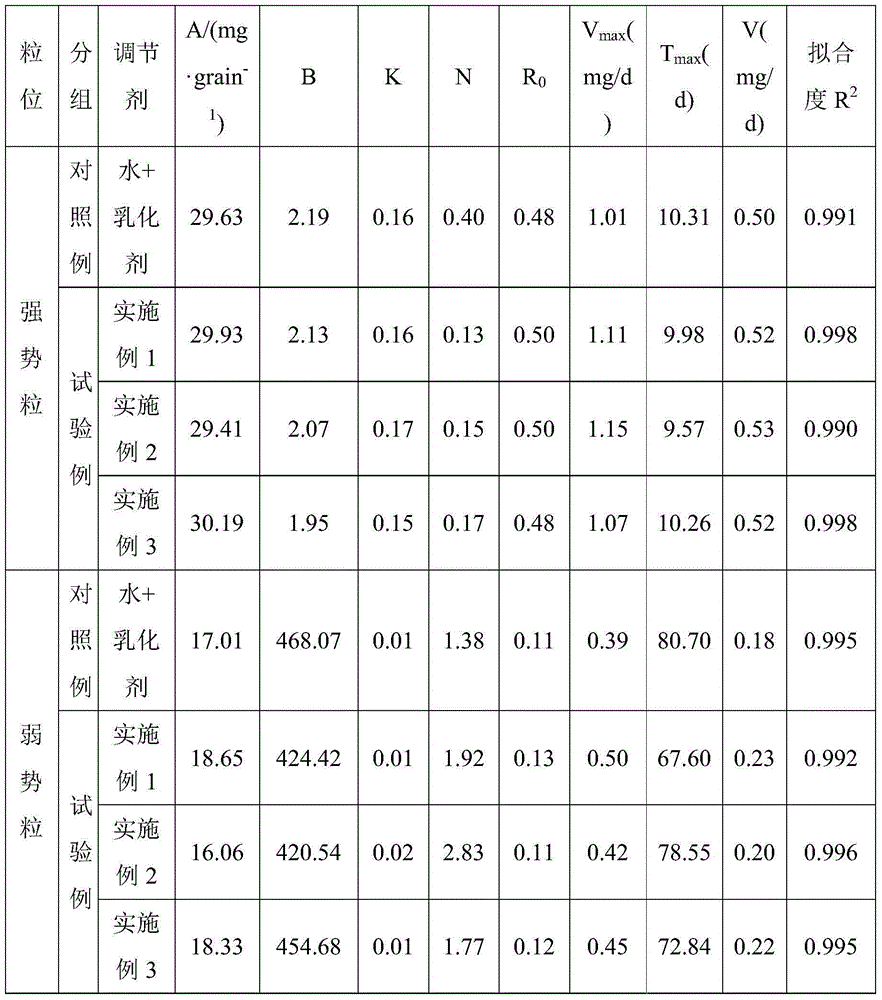

Examples

Embodiment 1

[0028] This embodiment improves the chemical regulator for rice grain filling and filling. The quality of each component in 1L regulator is: 0.83g of salicylic acid, 42.27g of vitamin C, 60.00g of zinc sulfate, 75.00g of potassium dihydrogen phosphate, and 45.00g of boric acid , emulsifier 3.00g, and the balance is water.

[0029] This embodiment improves the preparation method of the chemical regulator for rice grain filling and filling, and the specific operation steps are:

[0030] 1) Weigh 0.83g of analytically pure salicylic acid, add 420ml of water to fully dissolve, and make a salicylic acid solution;

[0031] 2) Weigh 42.27g of analytically pure vitamin C, add 130ml of water to fully dissolve, and make vitamin C solution;

[0032] 3) Weigh 60.00 g of analytically pure zinc sulfate and 75.00 g of potassium dihydrogen phosphate, add 340 ml of water to fully dissolve, and make zinc sulfate and potassium dihydrogen phosphate solution;

[0033] 4) After mixing the solutio...

Embodiment 2

[0037] The present embodiment improves the chemical regulator for rice grain filling and filling. The quality of each component in the 1L regulator is: salicylic acid 0.58g, vitamin C 29.6g, zinc sulfate 42g, potassium dihydrogen phosphate 52.5g, boric acid 31.5g, Emulsifier 2.1g, balance water.

[0038] This embodiment improves the preparation method of the chemical regulator for rice grain filling and filling, and the specific operation steps are:

[0039] 1) Weigh 0.58g of analytically pure salicylic acid, add 420ml of water to fully dissolve, and make a salicylic acid solution;

[0040] 2) Weigh 29.6g of analytically pure vitamin C, add 130ml of water to fully dissolve, and make vitamin C solution;

[0041] 3) Weigh 42g of analytically pure zinc sulfate and 52.5g of potassium dihydrogen phosphate, add 340ml of water to fully dissolve, and make zinc sulfate and potassium dihydrogen phosphate solution;

[0042] 4) After mixing the solutions prepared in steps 1), 2), and 3)...

Embodiment 3

[0046] This embodiment improves the chemical regulator for rice grain filling and filling. The quality of each component in the 1L regulator is: 1.08g of salicylic acid, 55g of vitamin C, 78g of zinc sulfate, 97.5g of potassium dihydrogen phosphate, 58.5g of boric acid, emulsified The dosage is 3.9g, and the balance is water.

[0047] This embodiment improves the preparation method of the chemical regulator for rice grain filling and filling, and the specific operation steps are:

[0048] 1) Weigh 1.08g of analytically pure salicylic acid, add 420ml of water to fully dissolve, and make a salicylic acid solution;

[0049] 2) Weigh 55g of analytically pure vitamin C, add 130ml of water to fully dissolve, and make vitamin C solution;

[0050] 3) Weigh 78g of analytically pure zinc sulfate and 97.5g of potassium dihydrogen phosphate, add 340ml of water to fully dissolve, and make zinc sulfate and potassium dihydrogen phosphate solution;

[0051] 4) After mixing the solutions pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com