Cigarette core capable of preventing cigarette burning cone from dropping and method for manufacturing same

A technology for burning cones and cigarette cores, which is used in tobacco, cigar manufacturing, and other directions to achieve the effects of improving porosity, reducing environmental pollution and uniform cigarette quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

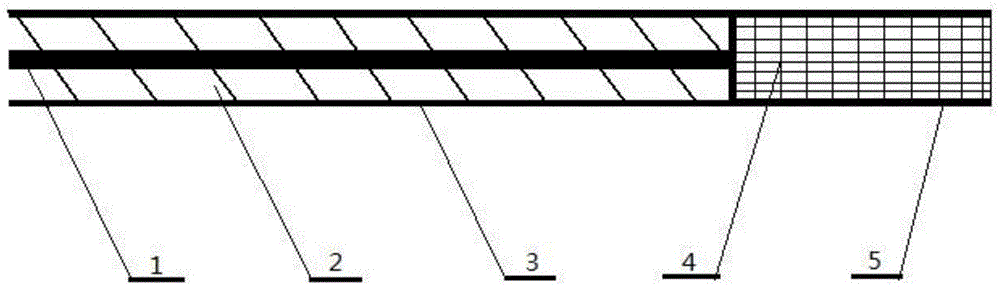

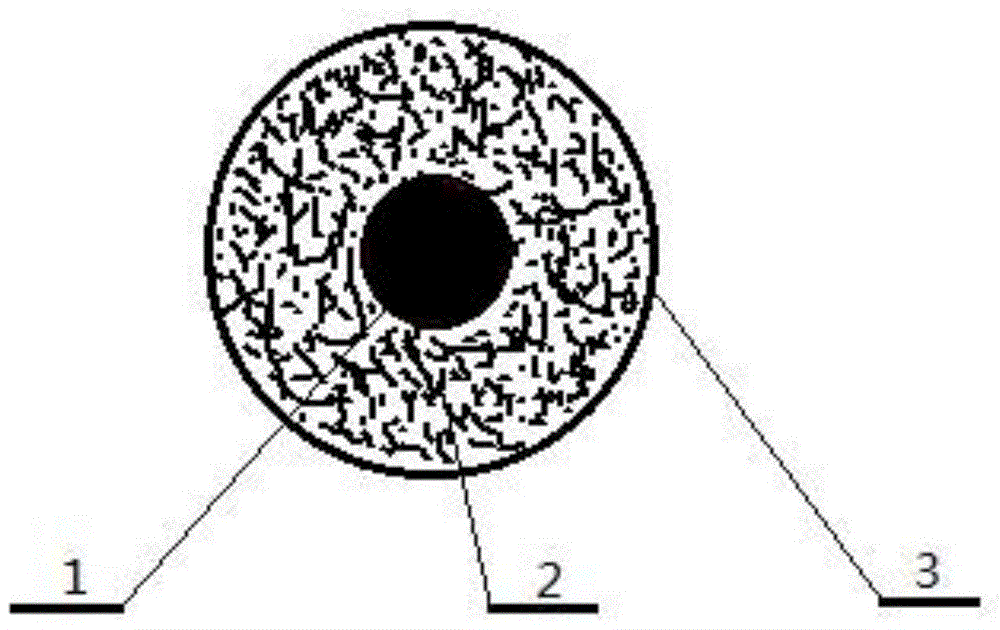

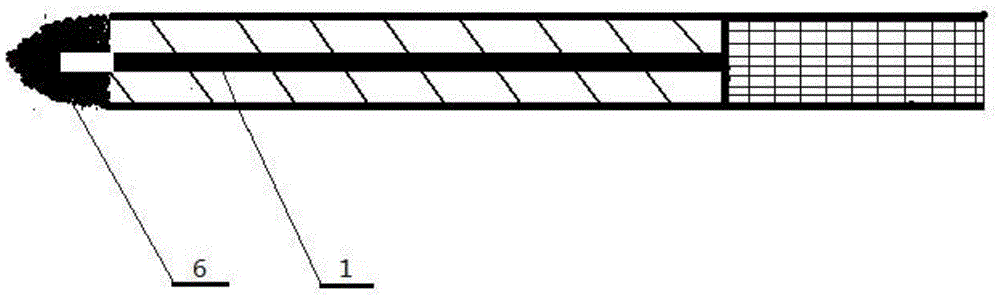

[0018] refer to Figure 1-Figure 3 As shown, a cigarette core for preventing the cigarette burning cone from falling includes a cigarette core 1, shredded tobacco 2, cigarette paper 3, filter rod 4 and tipping paper 5, the cigarette paper 3 wraps the shredded tobacco 2, and the shredded tobacco 2 wraps the cigarette core 1, The tipping paper 5 wraps the filter rod 4 and connects it behind the cigarette core 1, shredded tobacco 2 and cigarette paper 3. After the cigarette core 1, shredded tobacco 2 and cigarette paper 3 are ignited, a combustion cone 6 is produced. The cigarette core is made of the following raw materials : Tobacco stems, tobacco waste or tobacco substitutes, leavening agents, sugar spices, adhesive materials, said tobacco stems are tobacco stalks or tobacco stems after removing tobacco leaves when making flue-cured tobacco; said tobacco wastes are generated during cigarette production Tobacco dust, second-class waste tobacco leaves or waste recycled cut tobacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com