Hydroxyapatite nanoparticle with antitumor activity, preparation method and application thereof

A technology of hydroxyapatite and nanoparticles, which can be used in the fields of antineoplastic drugs, active ingredients of phosphorus compounds, powder delivery, etc. It can solve problems such as different preparation methods, no antitumor effect of nanoparticles, and uneven antitumor effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

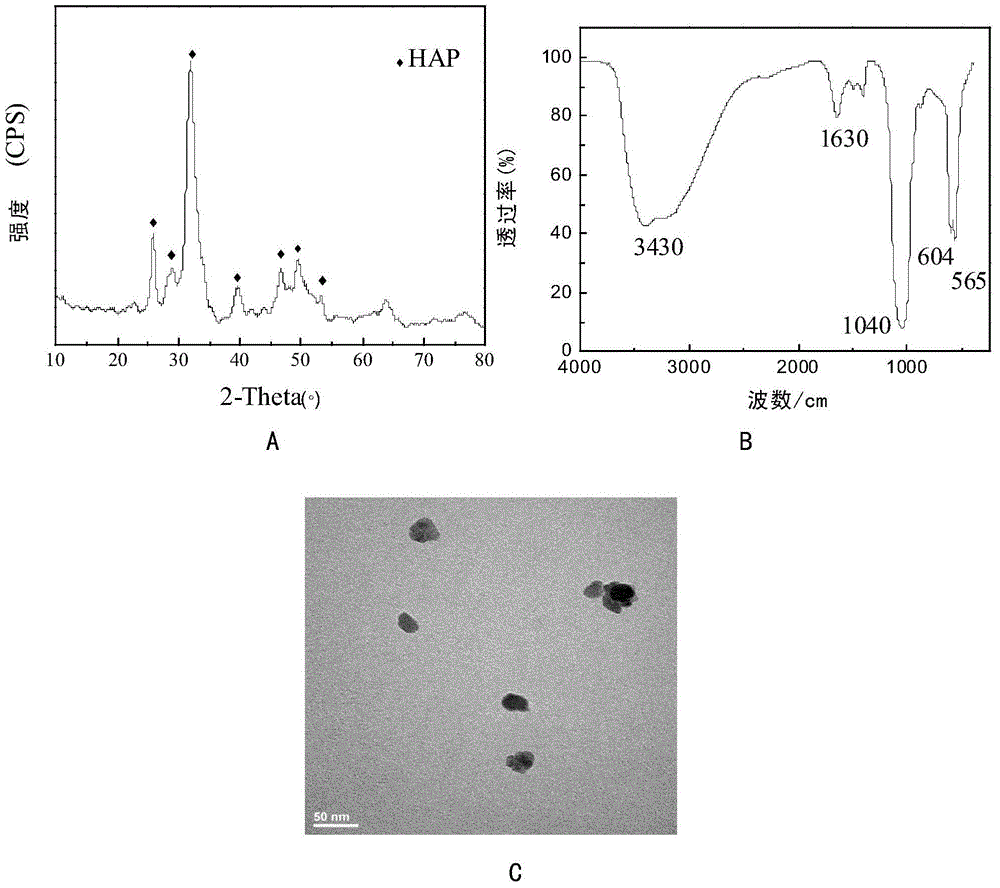

[0073] Example 1, Preparation and Characterization of Hydroxyapatite Nanoparticles HAPN-1

[0074] Weigh 18.89 g Ca(NO 3 ) 2 and 6.34 g (NH 4 ) 2 HPO 4 , were dissolved in 400mL and 240mL of high-purity water, and the two raw materials were prepared into 0.2M aqueous solution. Put the prepared solution into a 4°C refrigerator for pre-freezing, then place the pre-frozen solution in an ice-water bath, and mix the above (NH 4 ) 2 HPO 4 Ca(NO 3 ) 2 Mix in the solution, and adjust the pH of the reaction system to 10-12 with ammonia water; then stir and react overnight in an ice-water bath, and keep the pH>10 during the reaction. After the reaction is complete, the reaction solution is centrifuged to collect the prepared particles, and the particles are alternately washed with high-purity water and ethanol for 3 times; then placed in a freeze dryer for 24 hours; finally, the sample is placed in a muffle furnace at 600°C After calcining for 2 hours, hydroxyapatite nanoparti...

Embodiment 2

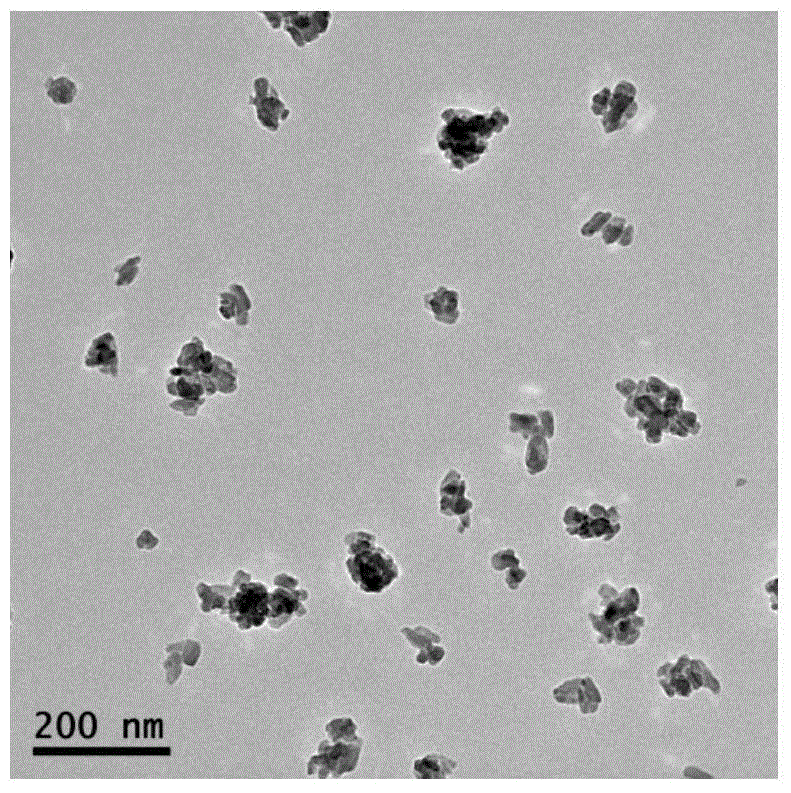

[0080] Example 2, Preparation and Characterization of Hydroxyapatite Nanoparticles HAPN-2

[0081] Weigh 18.89 g Ca(NO 3 ) 2 and 6.34 g (NH 4 ) 2 HPO 4 , were dissolved in 400mL and 240mL of high-purity water to prepare a 0.2M aqueous solution. The prepared solution was preheated in a 40°C water bath, and then the preheated solution was placed in a 40°C water bath, and the above (NH 4 ) 2 HPO 4 Ca(NO 3 ) 2Mix in the solution, and adjust the pH of the reaction system to 10-12 with ammonia water; then stir and react overnight in a water bath at 40°C, and keep the pH>10 during the reaction. After the reaction is complete, the reaction solution is centrifuged to collect the prepared particles, and the particles are alternately washed with high-purity water and ethanol for 3 times; then placed in a freeze dryer for 24 hours; finally, the sample is placed in a muffle furnace at 600°C Calcined for 2 hours to obtain hydroxyapatite nanoparticles (referred to as HAPN-2).

[0...

Embodiment 3

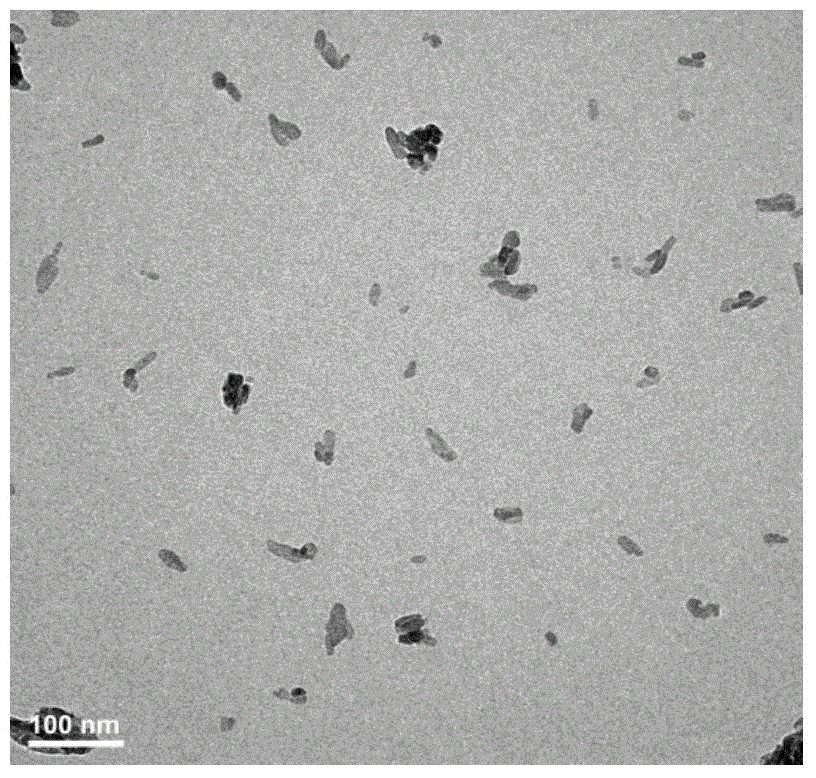

[0084] Example 3, Preparation and Characterization of Base Apatite Nanoparticles HAPN-3

[0085] Weigh 18.89 g Ca(NO 3 ) 2 and 6.34 g (NH 4 ) 2 HPO 4 , were dissolved in 400mL and 240mL of high-purity water to prepare a 0.2M aqueous solution. The prepared solution was preheated in a 60°C water bath, and then the preheated solution was placed in a 60°C water bath, and the above (NH 4 ) 2 HPO 4 Ca(NO 3 ) 2 Mix in the solution, and adjust the pH of the reaction system to above 10 with ammonia water; then stir and react overnight in a water bath at 60°C, and keep the pH>10 during the reaction. After the reaction is complete, the reaction solution is centrifuged to collect the prepared particles, and the particles are alternately washed with high-purity water and ethanol for 3 times; then placed in a freeze dryer for 24 hours; finally, the sample is placed in a muffle furnace at 600°C Calcined for 2 hours, the hydroxyapatite nanoparticles were obtained, denoted as HAPN-3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com