Preparation method of zero-valent iron ball

A nano-zero-valent iron and iron ball technology, applied in nanotechnology and other directions, can solve the problems that nano-zero-valent iron cannot guarantee effective contact reaction, the processing efficiency of the treatment system is reduced, and the nano-iron powder is difficult to separate, etc., to achieve rapid decontamination. high performance, high removal efficiency, and low cost of pelletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

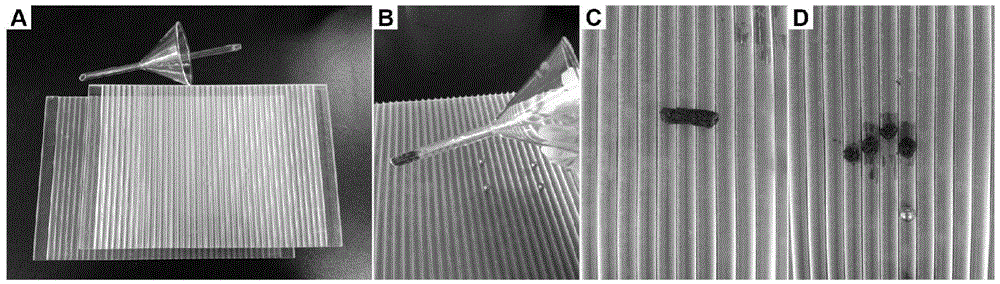

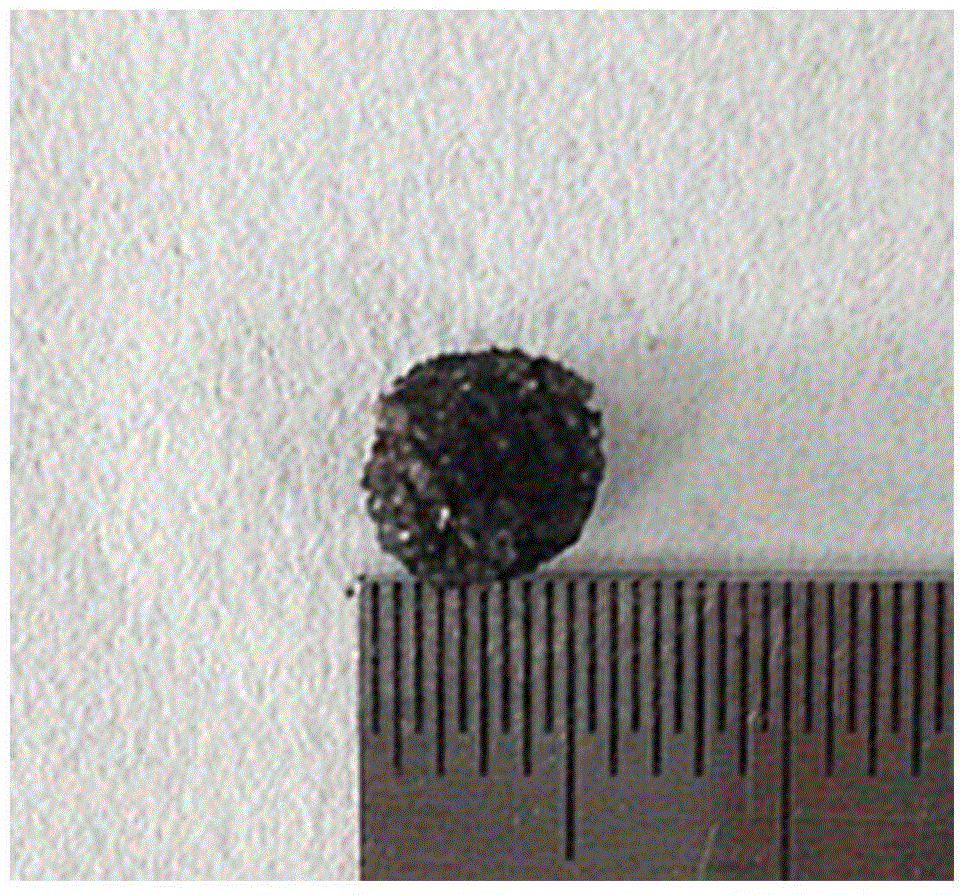

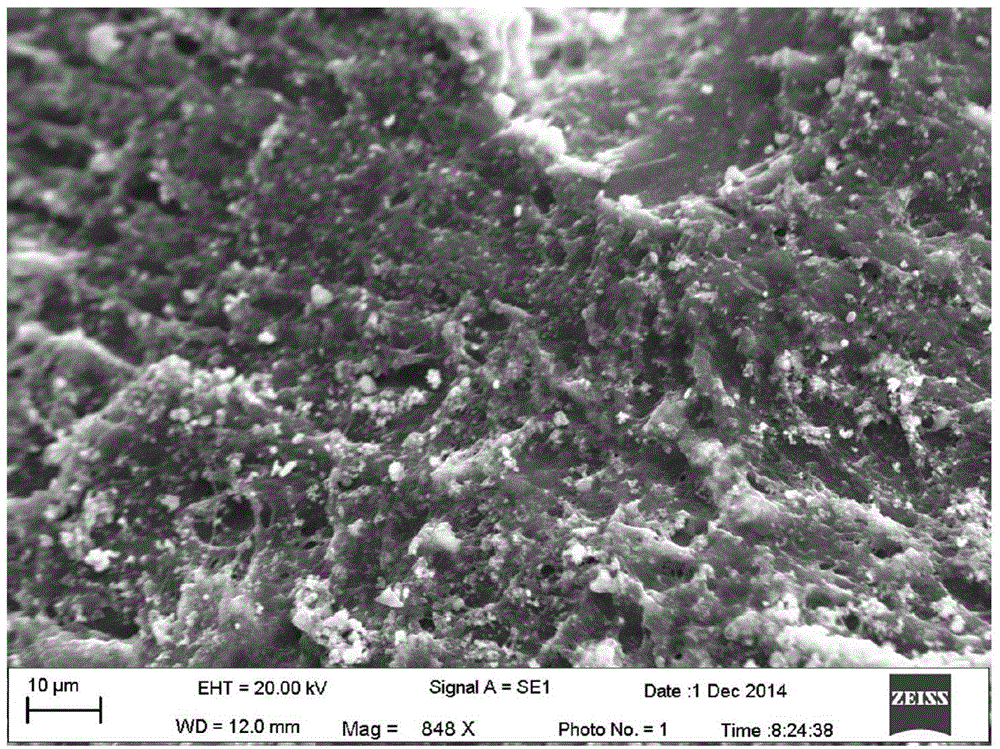

Image

Examples

Embodiment 1

[0066] A method for preparing zero-valent iron balls, comprising:

[0067] Ⅰ. Preparation of air-stable guar gum nanometer zero-valent iron powder:

[0068] A, prepare guar gum solution

[0069] Add food-grade guar gum solid powder into ultrapure water, then heat and stir to dissolve, and obtain a mass percentage of 0.05%.

[0070] of guar gum solution.

[0071] B. Deoxygenation

[0072] In a three-necked flask, 0.2780g FeSO 4 ·7H 2 O was mixed with 30ml of the above-mentioned guar gum solution, then passed into nitrogen deoxygenation for 20-40min, and mechanically stirred for 5-10min so as to mix uniformly to obtain a mixed solution;

[0073] C. Preparation of nano-iron solution

[0074] Weigh 0.2160g of KBH 4Add dropwise 1ml of NaOH solution with a concentration of 0.5mol / L, then add 20ml of the above-mentioned guar gum solution, and react for 30min under mechanical stirring to obtain a black nano-zero-valent iron solution;

[0075] D. Preparation of nano-sized zero-...

Embodiment 21

[0083] A method for preparing zero-valent iron balls. The difference from Example 1 is that the prepared iron balls are soaked in a deoxygenated absolute ethanol solution and stabilized for 12 hours after forming the balls.

Embodiment 22

[0085] A method for preparing zero-valent iron balls. The difference from Example 1 is that the prepared iron balls are immediately soaked in a deoxygenated absolute ethanol solution and stabilized for 18 hours after forming the balls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com