Simultaneous upgrading and tritium removal process of heavy water

A heavy water and process technology, applied in heavy water and other directions, can solve the problems of large gas loss, affecting the process material balance, adverse process economy, etc., to improve the effect, reduce one-time investment and operating costs, and the process flow is simple and efficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

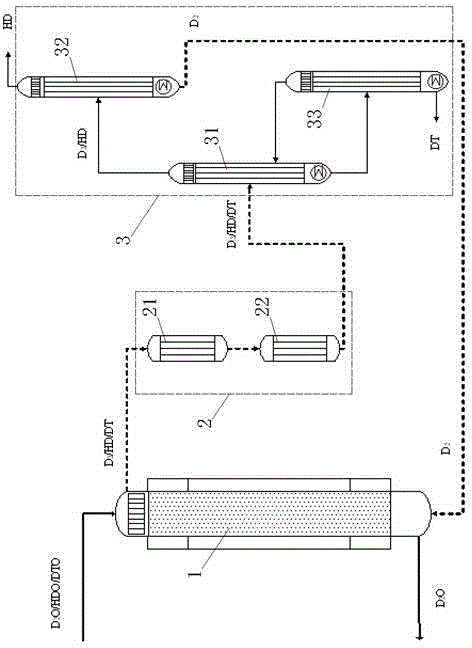

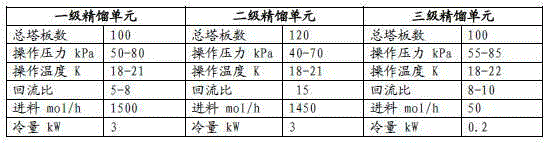

Method used

Image

Examples

Embodiment 1

[0031] The HDO mole fraction in heavy water to be treated is 3%, and the tritium concentration is 1011 Bq / L, its HDO content is higher.

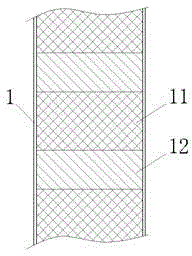

[0032] With Pt / C / PTFE as catalyst, with D 2 Perform isotope exchange with HDO and DTO in heavy water. The reaction is carried out in a catalytic exchange reaction device. The catalyst layer and packing layer of the reaction device are filled alternately. The packing layer is made of stainless steel θ rings. The liquid phase inlet of the catalytic exchange reaction device is set On the top, the liquid phase outlet is set at the bottom, the gas phase inlet is set at the bottom, and the gas phase outlet is set at the top.

[0033] In this embodiment, in the catalytic exchange reaction, the control reaction temperature is 30°C, the reaction pressure is 100KPa, D 2 The feed molar ratio with heavy water is 1:3. After the reaction through the catalytic exchange reaction device, the molar fraction of HDO in the product heavy water is 0.05%, and th...

Embodiment 2

[0038] The HDO mole fraction in heavy water to be treated is 0.3%, and the tritium concentration is 10 12 Bq / L, its content of tritium is higher.

[0039] With Pt / C / PTFE as catalyst, with D 2 Perform isotope exchange with HDO and DTO in heavy water. The reaction is carried out in a catalytic exchange reaction device. The catalyst layer and packing layer of the reaction device are filled alternately. The packing layer is made of stainless steel θ rings. The liquid phase inlet of the catalytic exchange reaction device is set On the top, the liquid phase outlet is set at the bottom, the gas phase inlet is set at the bottom, and the gas phase outlet is set at the top.

[0040] In the present embodiment, the control reaction temperature is 60°C, the reaction pressure is 200KPa, D 2 The feed molar ratio with heavy water is 1:4. After the reaction of the catalytic exchange reaction device, the protium in the product heavy water is 0.02%, and the tritium concentration is 10 10 Bq / ...

Embodiment 3

[0045] The HDO mole fraction in heavy water to be treated is 3%, and the tritium concentration is 10 12 Bq / L, its content of HDO and tritium is higher.

[0046] With Pt-SDB as catalyst, with D 2 Perform isotope exchange with HDO and DTO in heavy water. The reaction is carried out in a catalytic exchange reaction device. The catalyst layer and packing layer of the reaction device are filled alternately. The packing layer is filled with stainless steel triangular spiral packing. The liquid phase inlet of the catalytic exchange reaction device It is set on the top, the liquid phase outlet is set on the bottom, the gas phase inlet is set on the bottom, and the gas phase outlet is set on the top.

[0047] In this embodiment, the control reaction temperature is 90°C, the reaction pressure is 300KPa, D 2 The feed molar ratio with heavy water is 1:10. After the reaction of the catalytic exchange reaction device, the protium in the product heavy water is 0.05%, and the tritium conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com