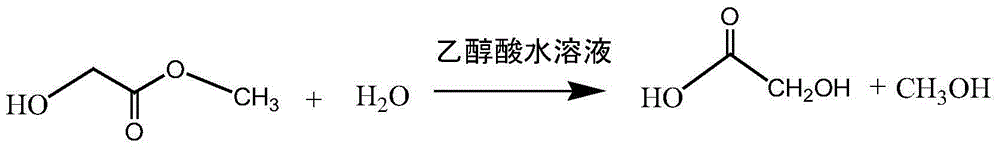

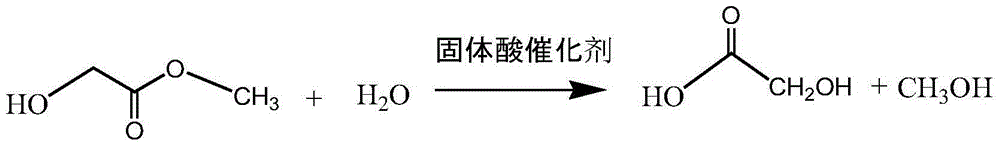

Method for producing aqueous solution of glycolic acid

A glycolic acid aqueous solution and production method technology, applied in the separation/purification of carboxylic acid compounds, preparation of carboxylic acid esters/lactones, organic chemistry, etc., can solve the problems of low yield, short catalyst life, low product purity, etc. Achieve the effect of high yield, low production cost, high purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The technique that the present invention produces glycolic acid by methyl glycolate comprises the steps:

[0028] 1) Inert Al 2 o 3 Porcelain balls are put into a fixed bed reactor, and methyl glycolate and water are mixed at a molar ratio of 1:10, and then enter the fixed bed reactor through a pump, with a space velocity of 2.5h -1 , the reaction temperature is 70°C, the reaction pressure is normal pressure, the conversion rate of methyl glycolate at the outlet of the fixed bed is 30.4%, and the selectivity of glycolic acid is 100%. The packing in the distillation is θ ring, the catalyst is 001*7, and the liquid hourly space velocity is 2.5h -1 , the number of theoretical plates is 25, the feeding position is at the 10th theoretical plate, the reaction area is at the 8th to 16th theoretical plate, the reflux ratio is 1:1, the vacuum degree is 50kPa, the reboiler temperature of the tower kettle is 80°C, the reaction process The discharge pipeline at the top of the mi...

Embodiment 2

[0030] According to the conditions and steps described in Example 1, change the type of catalyst in the continuous reaction rectification unit, specifically including 001*7, 001*14.5, D-72, NKC-9, Amberlyst 35, etc., the conversion rate of methyl glycolate was 99.0%, and the selectivity of glycolic acid was 99%.

Embodiment 3

[0032] According to the conditions and steps described in Example 1, the reactive distillation column adopts fillers of SM700, SM350, and SM500 mixed fillers, and the volume ratio of SM700, SM350, and SM500 is 1:1:1, and the final methyl glycolate conversion rate is 100%. , Glycolic acid selectivity 96.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com