Water-soluble protective ink and preparation method thereof

A technology for protecting ink and water-solubility, which is applied in the field of water-soluble protective ink and its preparation, can solve the problems of complex raw materials for the production of water-soluble protective ink, and achieves the advantages of easy-to-obtain raw materials, simple ink-making process, and no irritating odor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

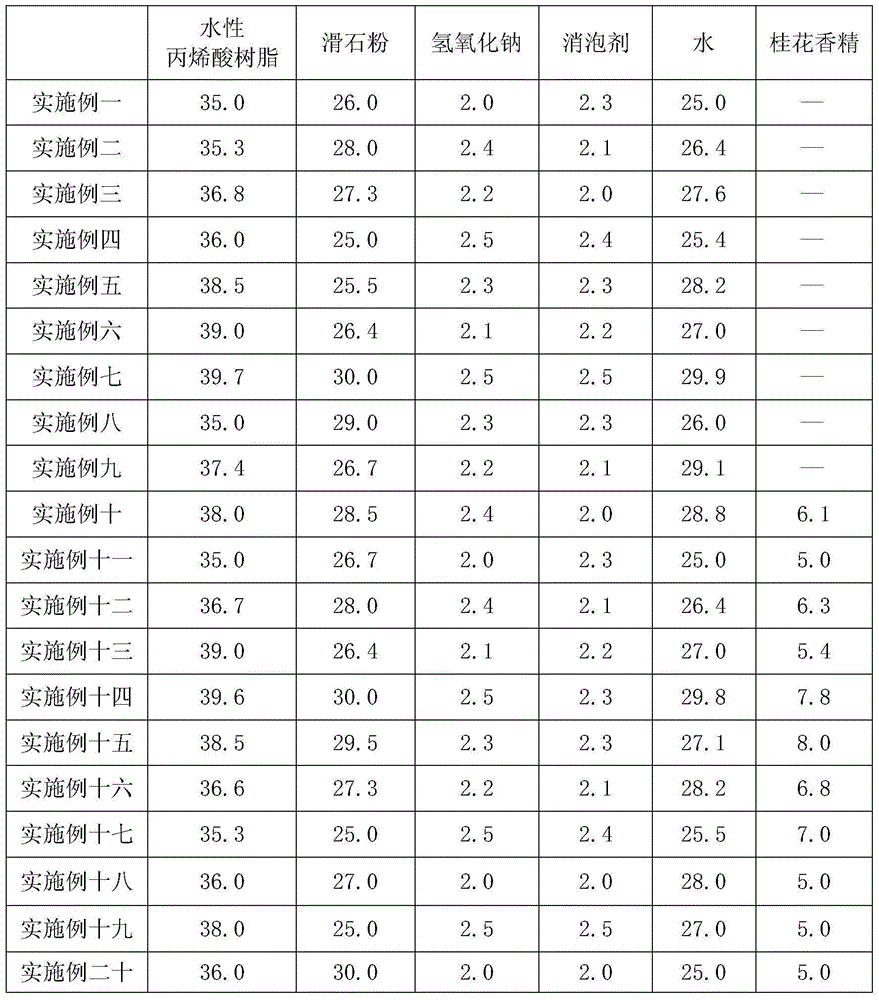

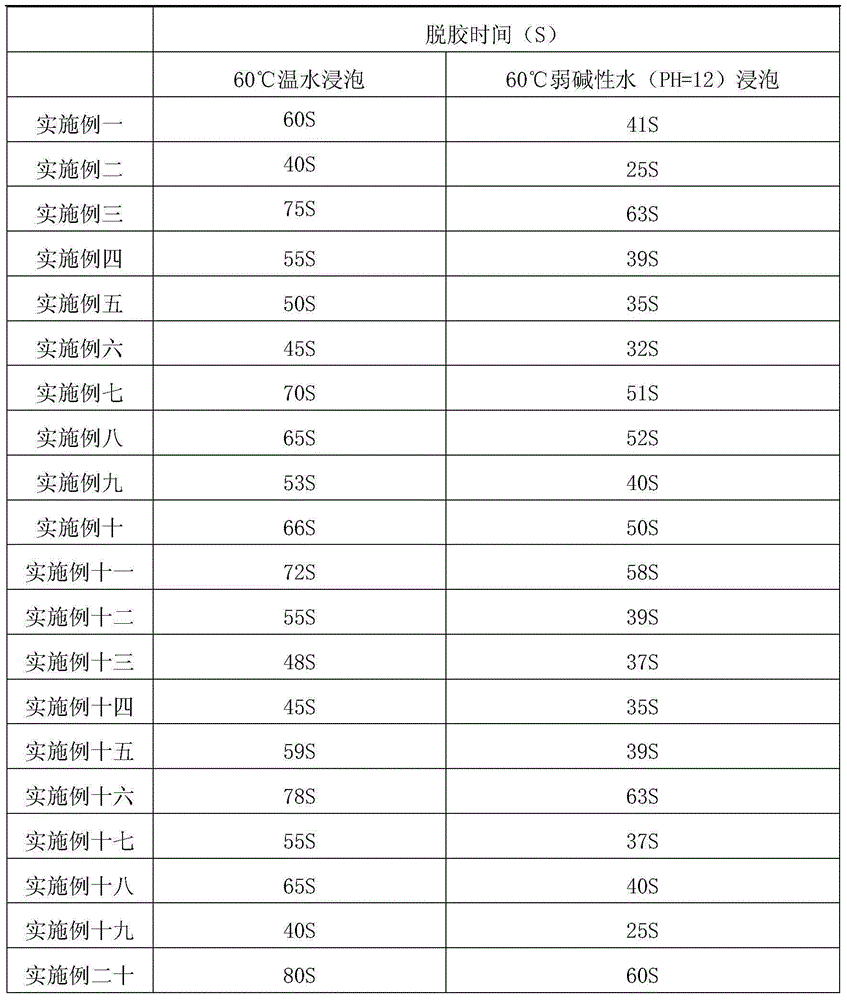

[0026] The application provides a water-soluble protective ink, comprising the following raw materials in parts by weight:

[0027] 35-40 parts of water-based acrylic resin, 25-30 parts of talcum powder, 2-2.5 parts of sodium hydroxide, 2-2.5 parts of defoamer, and 25-30 parts of water.

[0028] Preparation method: Dissolve 2-2.5 parts of sodium hydroxide with 25-30 parts of water, then mix evenly with 25-30 parts of water-based acrylic resin in a dispersing machine, the speed of the dispersing machine is 200-600 rpm, and batch Add 25-30 parts of talc powder, after adding talc powder, adjust the speed of the disperser to 600-1000 rpm, after dispersing for 0.5-1 hour, adjust the speed of the disperser to 200-600 rpm, add 2 -2.5 parts of defoamer and 5-8 parts of sweet-scented osmanthus essence; water-soluble ink is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com