A kind of low toxicity and low fluorescence lubricant for drilling fluid and preparation method thereof

A lubricant and drilling fluid technology, applied in the field of lubricants, can solve problems such as insufficient lubrication performance, poor temperature resistance performance, poor friction reduction effect, etc., to achieve performance reduction, good temperature resistance performance, and good lubrication effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

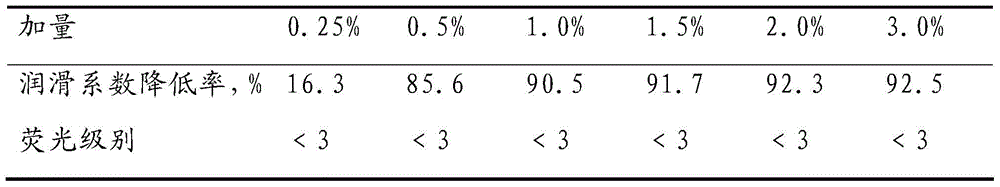

[0020] Example 1 A low-toxic, low-fluorescence, high-temperature-resistant, high-efficiency extreme-pressure lubricant for drilling fluid

[0021] (1) Raw material ratio

[0022] It is composed of the following components by weight fraction: 50% of base oil, 30% of emulsifier, 5% of penetrating agent, 5% of freezing point regulator, and 10% of extreme pressure agent.

[0023] (2) Preparation method

[0024] First add 50% industrial white oil to the reaction kettle, stir and heat up to 40-50°C, then add 20% Span-20 and 10% OP-7 for emulsification reaction, stir for 1 hour, then raise the temperature to 50°C -60°C, add 5% sodium alkyl sulfosuccinate and stir for 30 minutes, then add 10% chlorinated paraffin, continue stirring for 30 minutes, then stop heating, then add 5% poly-1,4 dioxanyl dimethylol The base alcohol is cooled while stirring, and poured out from the reaction kettle after being cooled to room temperature to obtain the low-toxicity, low-fluorescence, high-temper...

Embodiment 2

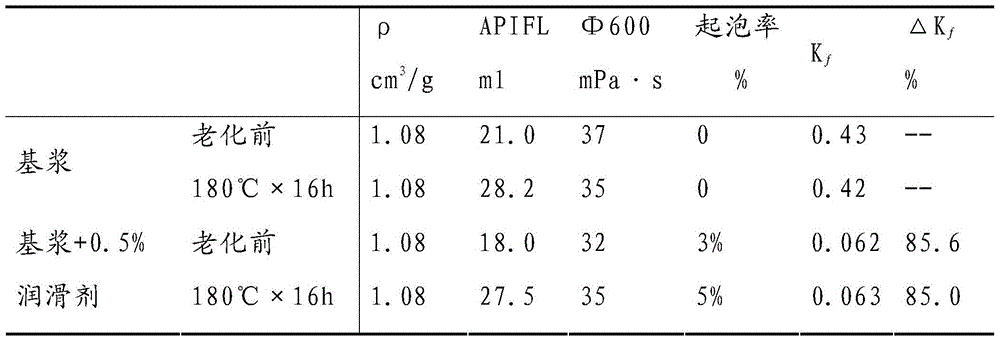

[0035] As shown in Table 2, the lubricant of Example 1 can withstand a high temperature of 180°C, has no adverse effect on the rheological properties and wall-building properties of the base slurry, and has almost no foaming. Example 2 A low-toxic, low-fluorescence, high-temperature-resistant, high-efficiency extreme-pressure lubricant for drilling fluid

[0036] (1) Raw material ratio

[0037] It consists of the following components by weight fraction: 60% of base oil, 25% of emulsifier, 5% of penetrating agent, 5% of freezing point regulator, and 5% of extreme pressure agent.

[0038] (2) Preparation method

[0039] First add 60% industrial white oil to the reaction kettle, stir, heat up to 40-50°C, then add 25% Span-80 for emulsification reaction, stir for 1 hour, raise the temperature to 50-60°C, add 5 After stirring for 30 minutes with % sulfated castor oil, add 5% 5-sulfurized olefin, stop heating after continuing to stir for 30 minutes, then add 5% poly-1,4-dioxanyl d...

Embodiment 3

[0042] Example 3 A low-toxicity, low-fluorescence, high-temperature-resistant, high-efficiency extreme-pressure lubricant for drilling fluid

[0043] (1) Raw material ratio

[0044] It consists of the following components by weight fraction: 70% of base oil, 20% of emulsifier, 3% of penetrating agent, 2% of freezing point regulator, and 5% of extreme pressure agent.

[0045] (2) Preparation method

[0046] First add 70% industrial white oil to the reaction kettle, stir, heat up to 40-50°C, then add 20% OP-10 for emulsification reaction, stir for 1 hour, raise the temperature to 50-60°C, add 3% Sodium alkyl sulfonate or secondary alkyl sulfonate was stirred for 30 minutes, then added 5% phosphate, continued stirring for 30 minutes, then stopped heating, then added 2% poly-1,4 dioxane dimethylol alcohol, while Cool while stirring, pour out from the reaction kettle after cooling to room temperature, and obtain the low-toxicity, low-fluorescence, high-temperature-resistant, high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com