Heat treatment method of 304 type antibacterial stainless steel plate strip

A technology of antibacterial stainless steel and heat treatment methods, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of low damage corrosion resistance, insufficient antibacterial function of austenitic antibacterial stainless steel, improper antibacterial heat treatment system, etc., to achieve The effect of broadening the market prospect and improving the actual use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

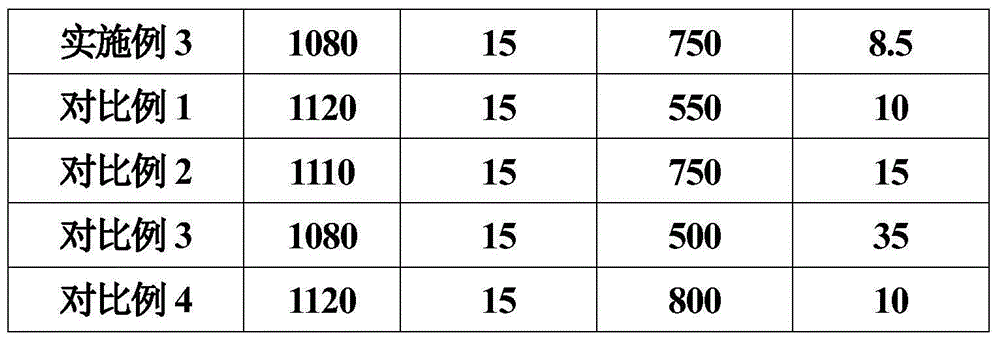

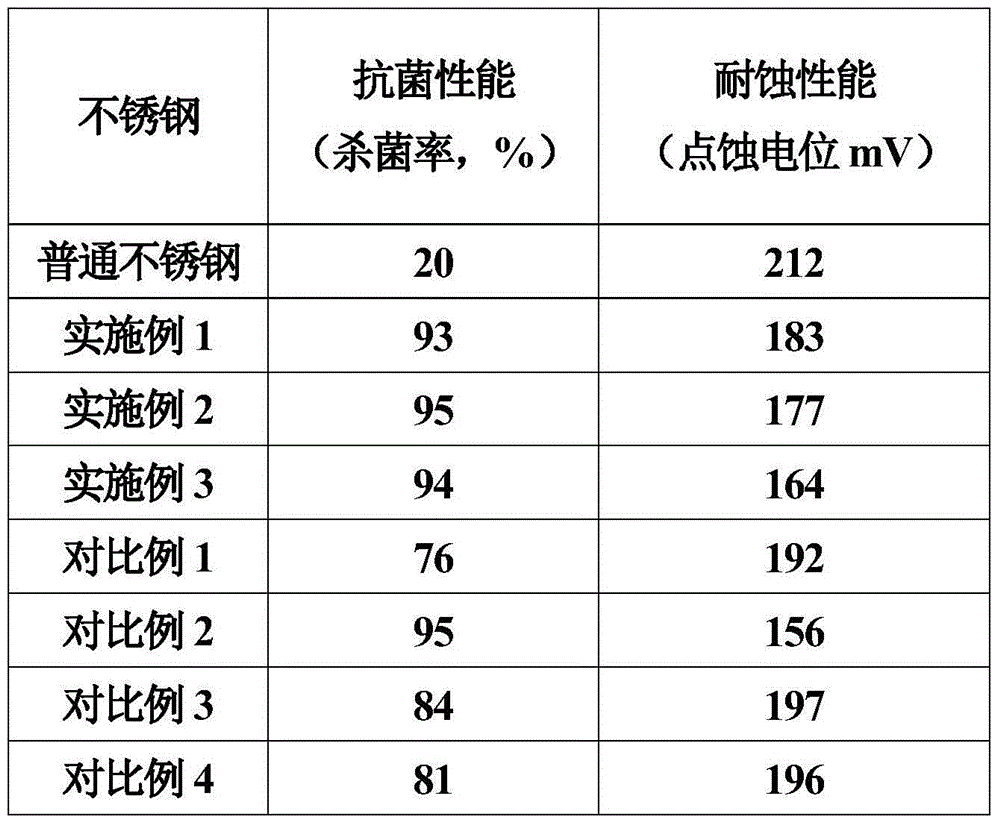

[0023] Embodiments 1 to 3 are shown in Table 1 for the heat treatment method of 304 type antibacterial stainless steel strips. Among them, the aging system can adopt a stepped heating mode, as follows:

[0024] In Examples 1 to 3, in the first stage (room temperature to less than 350° C.), heating at full speed according to the maximum power of the heating furnace, the heating rate is 150° C. / hour; in the second stage (350° C. to the prescribed aging temperature), the heating time is 8 hour; the third stage (prescribed aging temperature insulation section), holding time=106 minutes-0.13*aging temperature; the fourth stage, the belt cover nitrogen filled but cooled for 4.5 hours, to 420 ℃; the fifth stage, start split cooling (i.e. A cooling method that controls the flow and velocity of cooling water to achieve the purpose of controlling the cooling rate) to 110°C, the sixth stage, and out of the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pitting potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com