Connector for connecting FRR (Fiber-reinforced Plastic) rib material and connecting method

A technology for connecting joints and connecting methods, which is applied in the field of connecting FRP bars using connecting joints and connecting joints connecting FRP bars, which can solve the problems of wasting FRP bars and affecting the high-strength performance of FRP bars, and achieve improved Adhesive performance, solving mechanical connection problems, efficient and fast connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

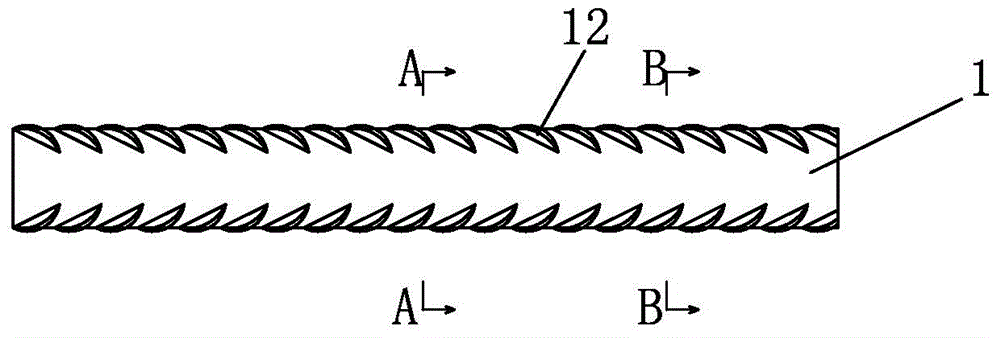

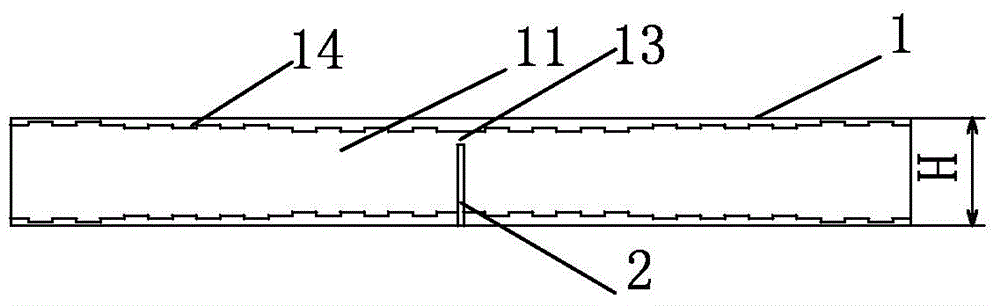

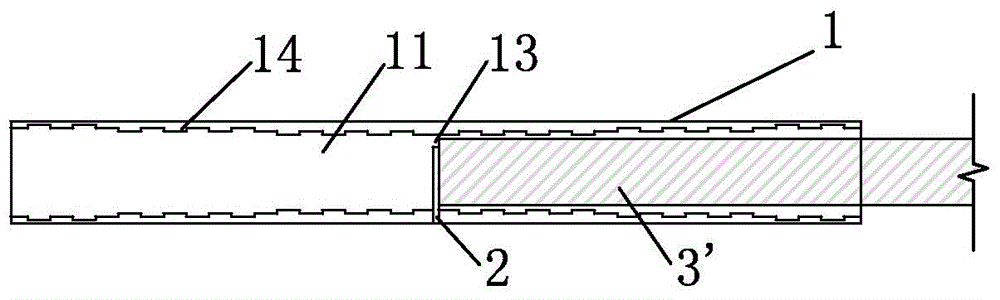

[0026] combine figure 1 and figure 2 As shown, the connection joint of the FRP bar of the present invention includes a circular stainless steel sleeve 1 and a central partition plate 2, the center of the sleeve 1 is provided with an axial through hole 11, and the central partition plate 2 is arranged on the sleeve 1 and fixed in the center of the axial through hole 11 of the sleeve 1, the central partition plate 2 is perpendicular to the axis of the sleeve 1, that is, parallel to the cross section of the sleeve 1, as Figure 4 As shown, the central partition plate 2 is approximately circular, and a gap 13 is formed between the central partition plate 2 and the inner wall of the sleeve 1, and the side wall of the central partition plate 2 is fixed to the inner wall of the sleeve 1, and the center partition The height of the highest point of the plate 2 is 0.75H, where H is the outer diameter of the sleeve 1 .

[0027] recombine graph and Figure 5 As shown, the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com