Method for manufacturing shallow trench isolation structure

A technology of isolation structure and manufacturing method, which is applied in the field of manufacturing shallow trench isolation structures, can solve problems such as increased stress and affecting the quality of lining oxide layers, and achieve the effects of releasing stress, short irradiation time, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

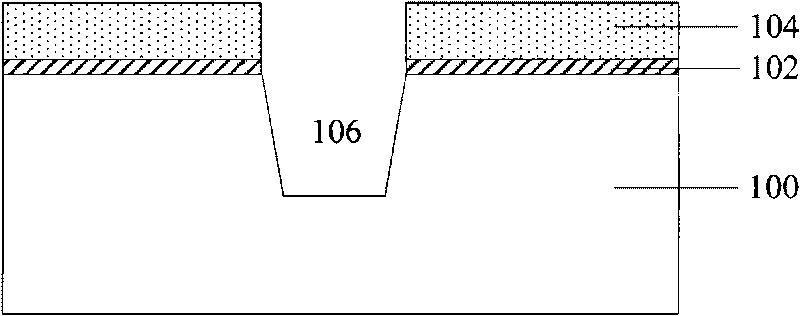

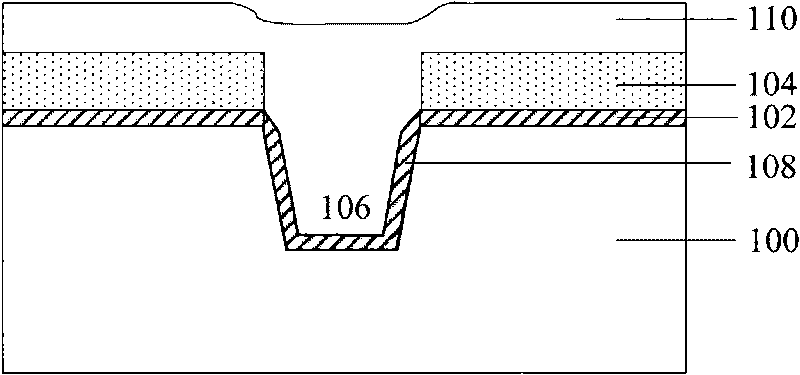

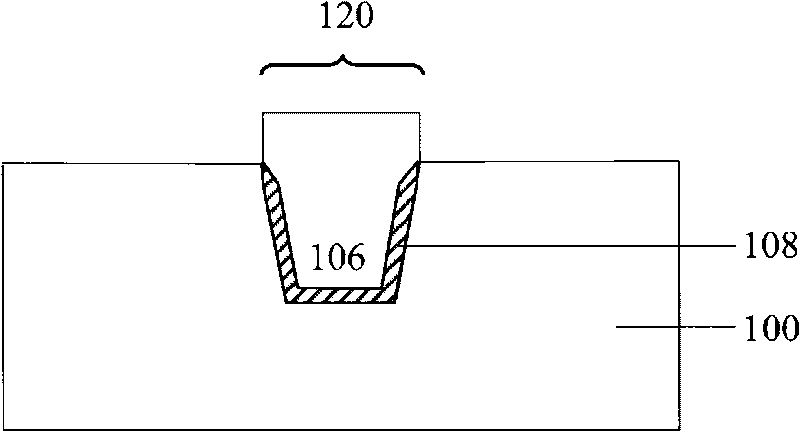

[0020] In the process of forming the shallow trench isolation structure in the existing technology, when the shallow trench is formed by etching, the etching gas or liquid will react with the semiconductor substrate in the shallow trench to form defects, or produce defects on the surface of the semiconductor substrate. If it is not repaired, it will affect the quality of the subsequently formed lining oxide layer and cause leakage current at the corner of the shallow trench. In addition, after the shallow trench is formed, the semiconductor substrate therein is easily oxidized by oxygen or water vapor when exposed to the air, forming a native oxide layer with poor density and uniformity. In order to solve the above problems, the present invention uses laser to heat-treat the inner wall of the shallow trench before forming the liner oxide layer. Due to the high intensity and short time characteristics of the laser, it can repair the defects on the semiconductor substrate in time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Laser power | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com