Multi-stage hydraulic cylinder internal tandem puller

A technology of internal serial connection and hydraulic cylinder, applied in the direction of fluid pressure actuation device, etc., can solve the problems of long maintenance time, limited underground space, poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

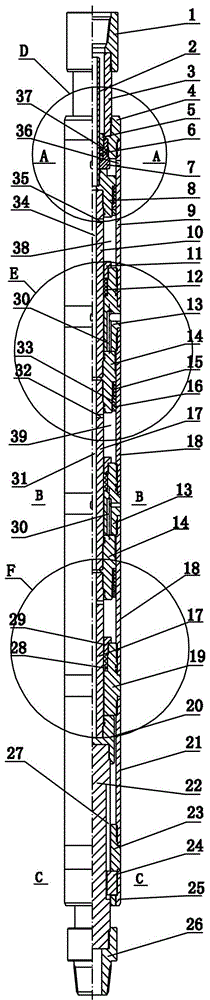

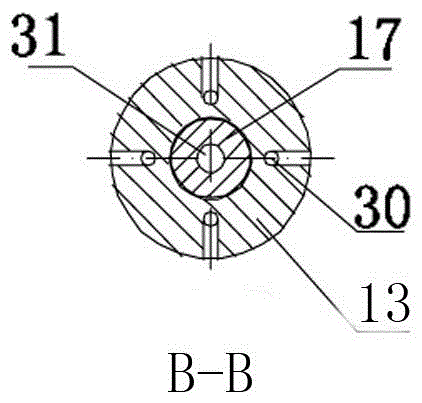

[0031] Such as figure 1 As shown, the multi-stage hydraulic cylinder internal tandem puller of the present invention is characterized in that it includes an upper outer coupling hoop 1, a working nipple 3, an upper hydraulic cylinder assembly, at least one set of lower hydraulic cylinder assemblies, and a lower connecting pipe of the cylinder barrel Assemblies and actuators, the upper outer coupling hoop 1 is threadedly connected with the working pup joint 3,

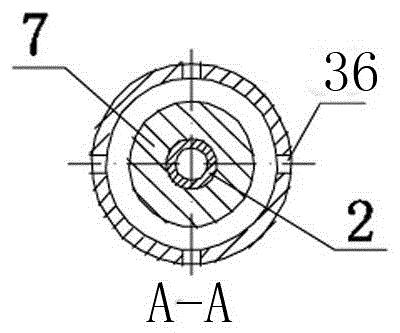

[0032] Such as figure 1 , 2 , 5, the upper hydraulic cylinder assembly is sealed by the cylinder upper collar 4, which is threadedly connected with the operation nipple 3 at the upper part, and the liquid inlet thin tube connected with the inner circle of the lower part of the cylinder upper collar 4 The assembly is composed of an upper hydraulic cylinder barrel 9 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com