Alcohol-based liquid fuel gasification burner

A liquid fuel and burner technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of failure to use normally, low calorific value of alcohol-based liquid fuel, incomplete combustion, etc., to achieve convenient promotion and use, and stable combustion Reliable, full and thorough gasification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

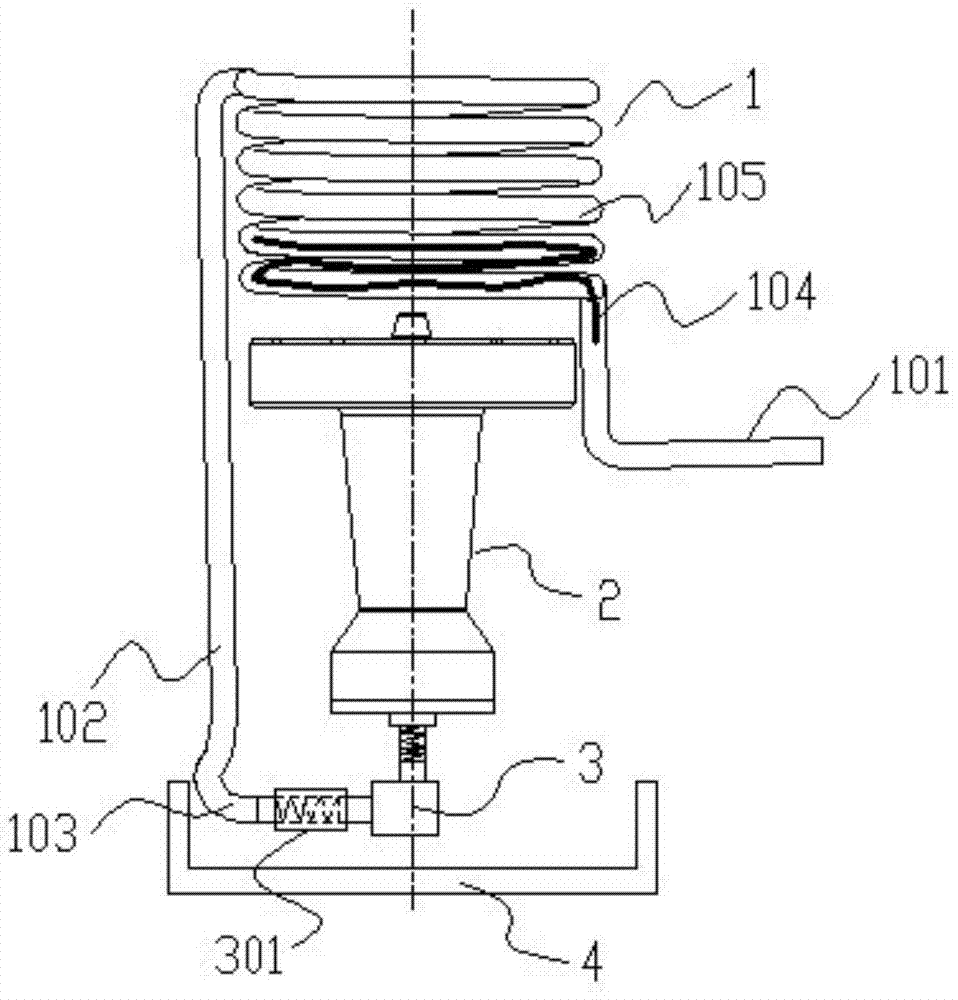

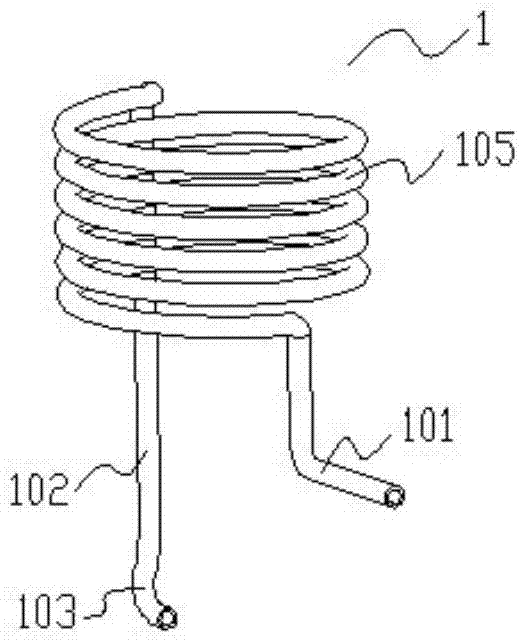

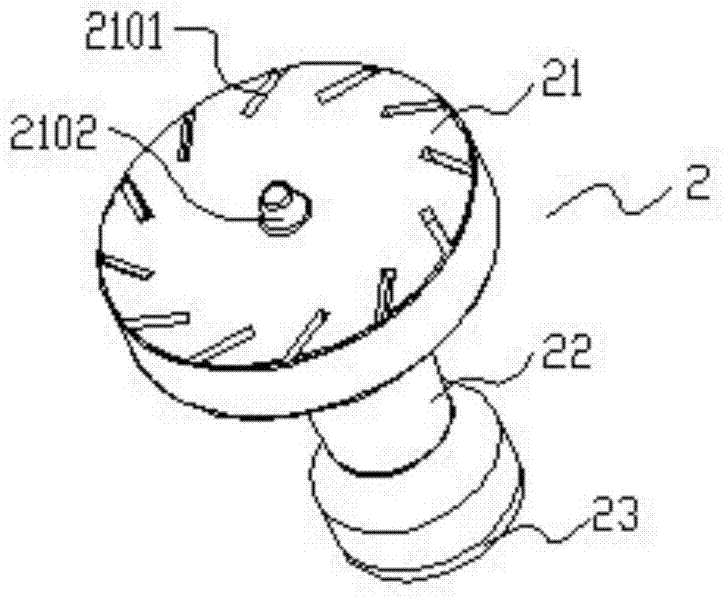

[0044] Such as Figure 1-Figure 9 As shown, the specific structure of the present invention is: it includes a fire distributor 2 and a gasification pipe 1 connected thereto, the fire distributor 2 is placed in the combustion cylinder 7, and the gasification pipe 1 is a multi-turn spiral formed by a metal pipe. Close-packed columnar structure, which is arranged directly above the fire distributor 2; the feed pipe 101 of the gasification pipe 1 is at the bottom of the spiral and spirals upward from the position of the fire distributor 2; the delivery pipe 1 of the gasification pipe 1 Trachea 102 falls v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com