Plastic inspection well comprehensive test detector

A plastic inspection well and detection device technology, applied in the direction of measuring devices, analysis materials, impact testing, etc., can solve the problems of inability to provide dynamic load, small size of workbench, single detection index, etc., to achieve high testing efficiency, reliable operation, The effect of many functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

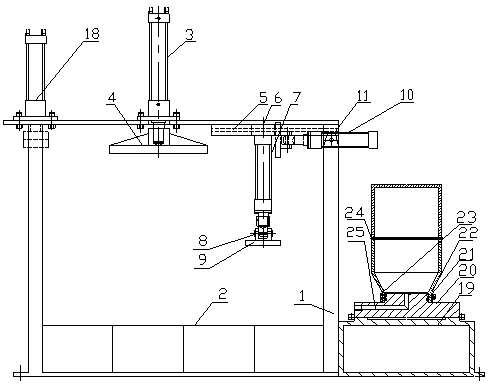

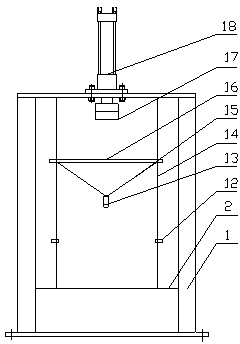

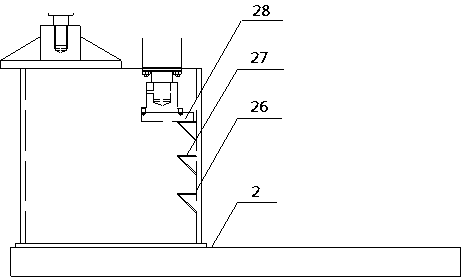

[0020] Embodiment 1: as Figure 1-4 As shown, a comprehensive test and detection device for plastic inspection wells, including frame 1, workbench Ⅰ 2, axial and radial loading hydraulic cylinder 3, pressure plate 4, guide rail Ⅰ 5, slider 6, shear loading hydraulic cylinder 7, pressure head connection Support 8, saddle pressure head 9, horizontal moving hydraulic cylinder 10, hinged support 11, limit block 12, heavy hammer 13, guide rail II 14, steel wire rope 15, beam 16, electromagnet 17, lifting hydraulic cylinder 18, water tank 19 , Workbench II 20, sealing ring 21, plastic inspection well 22, locking hoop 23, workpiece 26, step 27, pressing block 28, water pump 29, motor 30, two-position three-way electromagnetic reversing valve 31, pressure regulating pressure limiting Valve 32; frame 1 is fixed on the foundation through anchor bolts, workbench I2 is installed on the lower part of frame 1 through bolts, axial and radial loading hydraulic cylinder 3 is installed on the u...

Embodiment 2

[0021] Embodiment 2: as Figure 1-4 As shown, a comprehensive test and detection device for plastic inspection wells, including frame 1, workbench Ⅰ 2, axial and radial loading hydraulic cylinder 3, pressure plate 4, guide rail Ⅰ 5, slider 6, shear loading hydraulic cylinder 7, pressure head connection Support 8, saddle pressure head 9, horizontal moving hydraulic cylinder 10, hinged support 11, limit block 12, heavy hammer 13, guide rail II 14, steel wire rope 15, beam 16, electromagnet 17, lifting hydraulic cylinder 18, water tank 19 , Workbench II 20, sealing ring 21, plastic inspection well 22, locking hoop 23, workpiece 26, step 27, pressing block 28, water pump 29, motor 30, two-position three-way electromagnetic reversing valve 31, pressure regulating pressure limiting Valve 32; frame 1 is fixed on the foundation by bolts, workbench I2 is installed on the lower part of frame 1 by screws, axial radial loading hydraulic cylinder 3 is installed on the upper part of frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com