A single coil electromagnetic resonance detection method for metal pipeline damage

A metal pipeline, electromagnetic resonance technology, applied in the direction of material magnetic variables, etc., can solve the problems of unsatisfactory axial crack detection effect, complex detection system structure, cumbersome data processing process, etc., to facilitate long-distance transmission and storage analysis, system The effect of simple structure and rapid online detection of metal pipeline damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

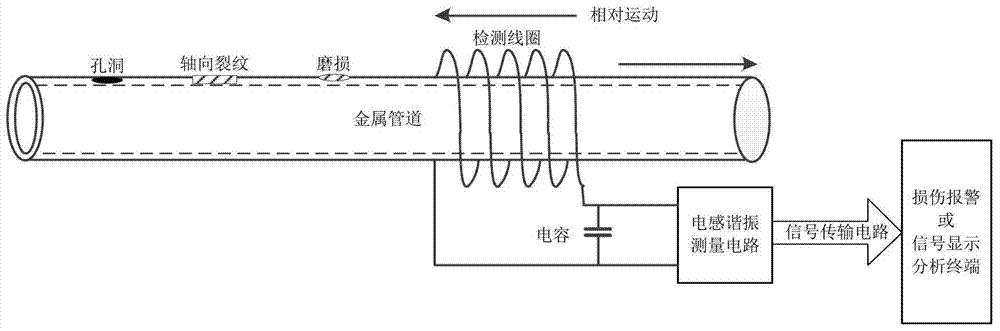

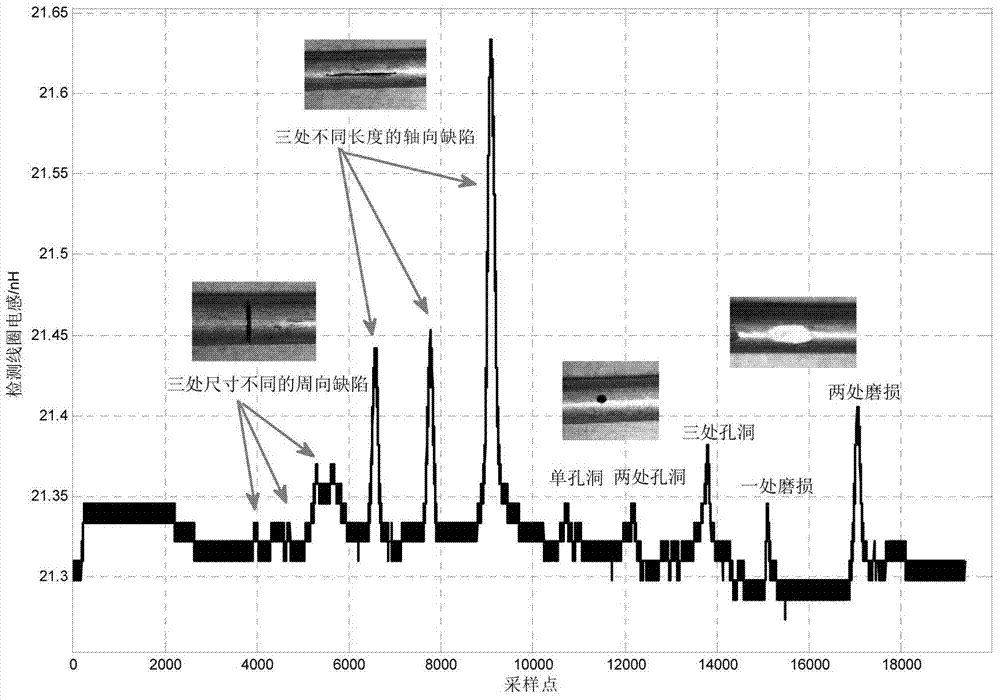

[0023] as attached figure 1 Shown is the detection system of the present invention that uses single coil electromagnetic resonance to detect pipeline damage. The system includes a detection coil, a capacitor, an electromagnetic resonance measurement circuit, a signal transmission circuit, and a damage alarm or signal display analysis terminal. Connect the detection coil and capacitor in parallel to form an LC resonant circuit. Among them, the detection coil is a wound coil or a PCB coil, and its number of turns is determined according to the inductance value of the detection coil when the pipeline to be inspected passes through the detection coil; the capacitance value of the parallel capacitor is also determined according to the inductance value of the detection coil and the inductance resonance measurement circuit The resonant frequency and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com