Array-type gamma irradiation dosimeter of FBAR structure on diaphragm

A radiation dose and array technology, applied in the field of array gamma radiation dosimeters, can solve the problems that temperature has a great influence on the FBAR resonant frequency, cannot detect the distribution of radiation dose, and does not have a temperature compensation layer, etc., and achieves improvement. The effect of temperature stability, easy wiring, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is described in detail below in conjunction with accompanying drawing:

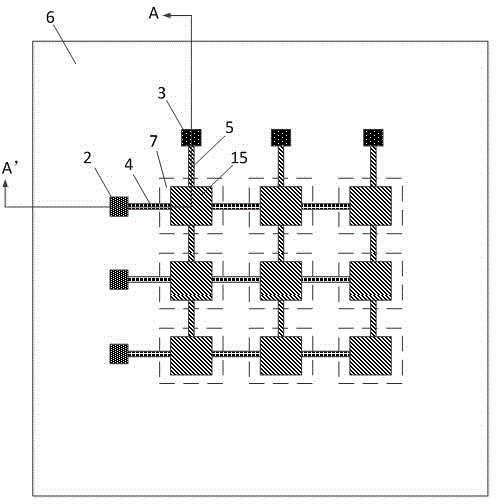

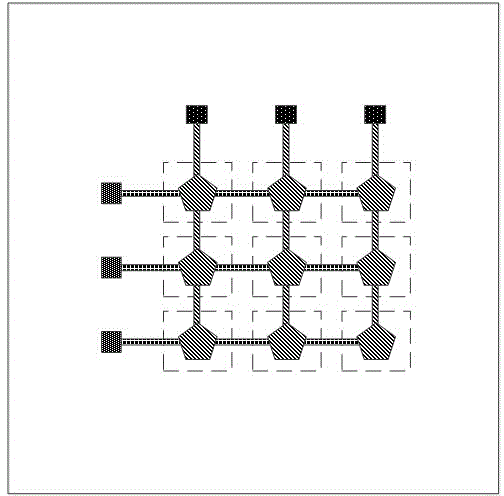

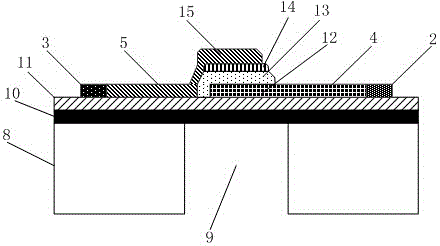

[0049] An array gamma radiation dosimeter with FBAR structure on the diaphragm, including a detection element 1, a composite film 6 and a Si base 8, the detection element 1 is on the composite film 6, the composite film 6 is used to support the detection element 1, and the Si base 8 Located under the composite film 6; the detection element 1 includes a number of FBARs distributed on the composite film 6 in a rectangular array, and the FBAR includes a bottom electrode 12, a piezoelectric layer 13 and a top electrode 15 from bottom to top, and a radiation sensitive layer 14 Set between the piezoelectric layer 13 and the bottom electrode 12 or between the piezoelectric layer 13 and the top electrode 15, the bottom electrode 12 is close to the upper surface of the composite film 6; the Si base 8 is provided with a number of cavities 9, the hollow The cavity 9 corresponds to the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com