Automatic assembling system of proton exchange membrane fuel cell stacks

A fuel cell stack and proton exchange membrane technology, applied in the field of automation systems, can solve problems such as difficult to effectively control the compression displacement of the stack, difficult to ensure consistency accurately, and large manual operation errors, so as to eliminate inhomogeneity and enhance functions , The effect of preventing lateral skewing and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

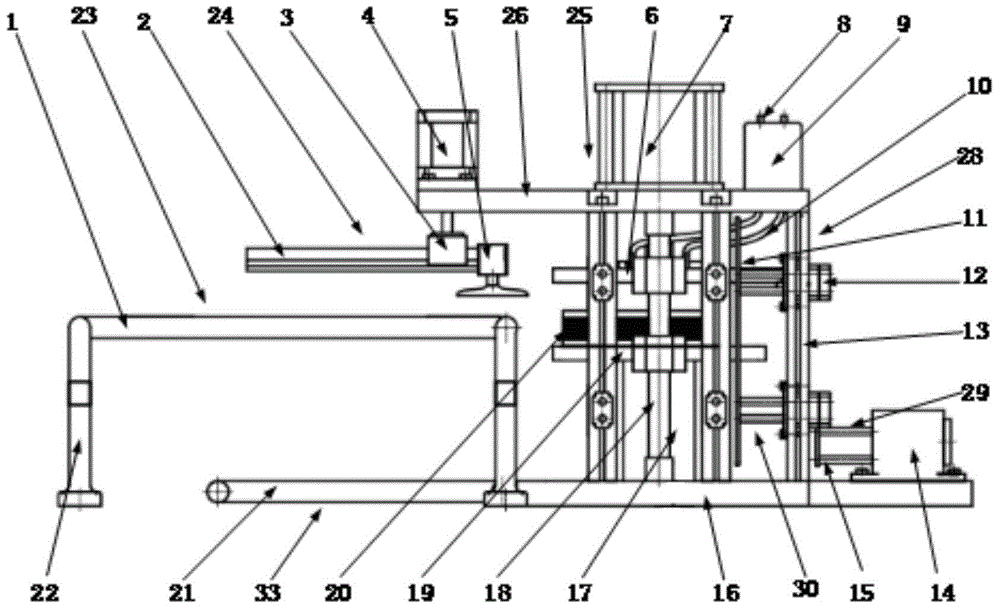

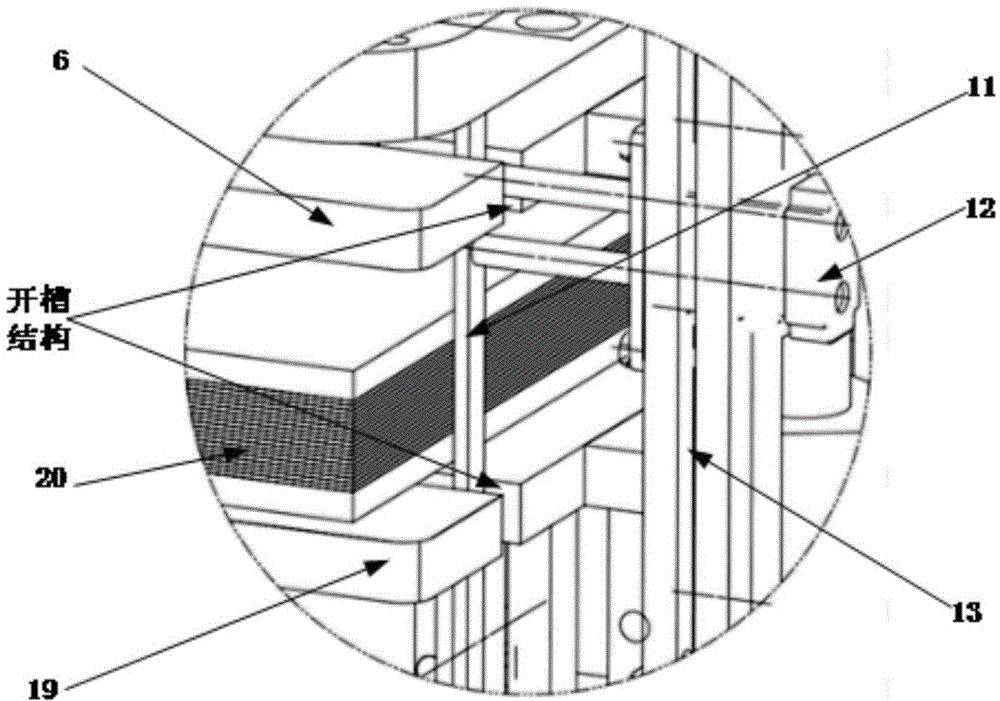

[0037] see Figure 2 to Figure 5 , the automatic assembly system for proton exchange membrane fuel cell stacks of the present invention includes a frame 28, a component transfer mechanism 23, a component pick-up mechanism 24, a stack assembly mechanism 25, an online seal detector 9, a displacement control mechanism 38, and a lateral limit Mechanism 30, stack push-out mechanism 29, stack transfer mechanism 33 and corresponding control system; wherein: component pick-up mechanism, stack assembly mechanism, online seal detector, displacement control mechanism and lateral limit mechanism are respectively installed on different parts of the rack. position, the stack ejection mechanism is installed on one side of the bottom of the rack, the component transfer mechanism is set at the component entrance of the rack, and the stack transfer mechanism is set at the stack exit of the rack. Frame 28 among the present invention comprises frame upper platform 26, frame base 16, guide rail 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com