Miniature microphone of FBAR structure on diaphragm

A microphone and diaphragm technology, applied in electrostatic transducer microphones and other directions, can solve the problems of piezoelectric materials being easily affected by external temperature and measurement errors, and achieve improved temperature stability, high operating frequency, and good manufacturability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

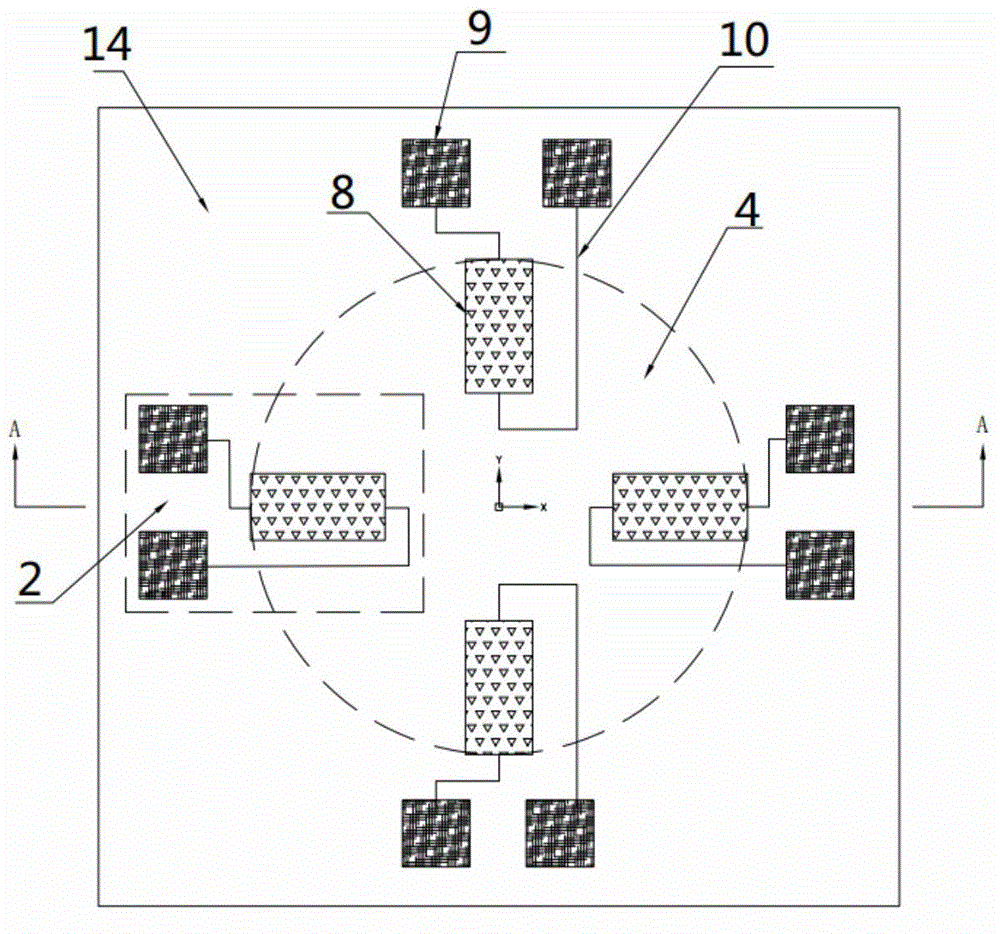

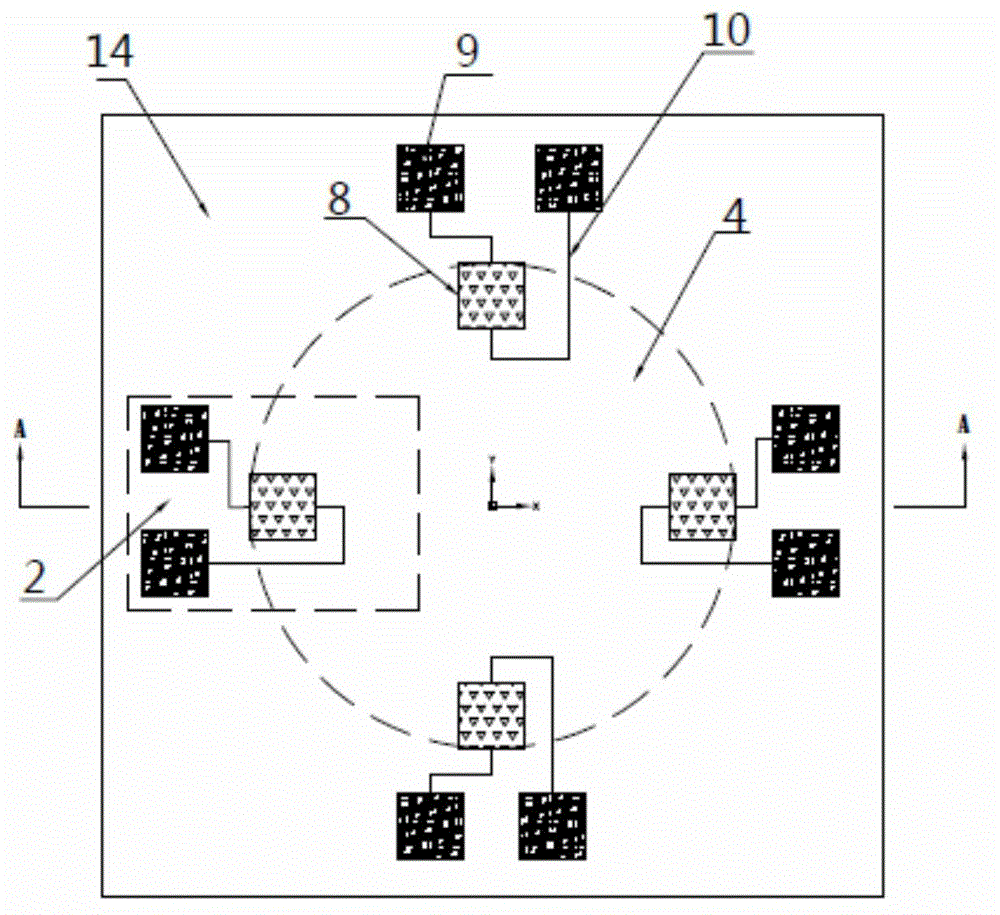

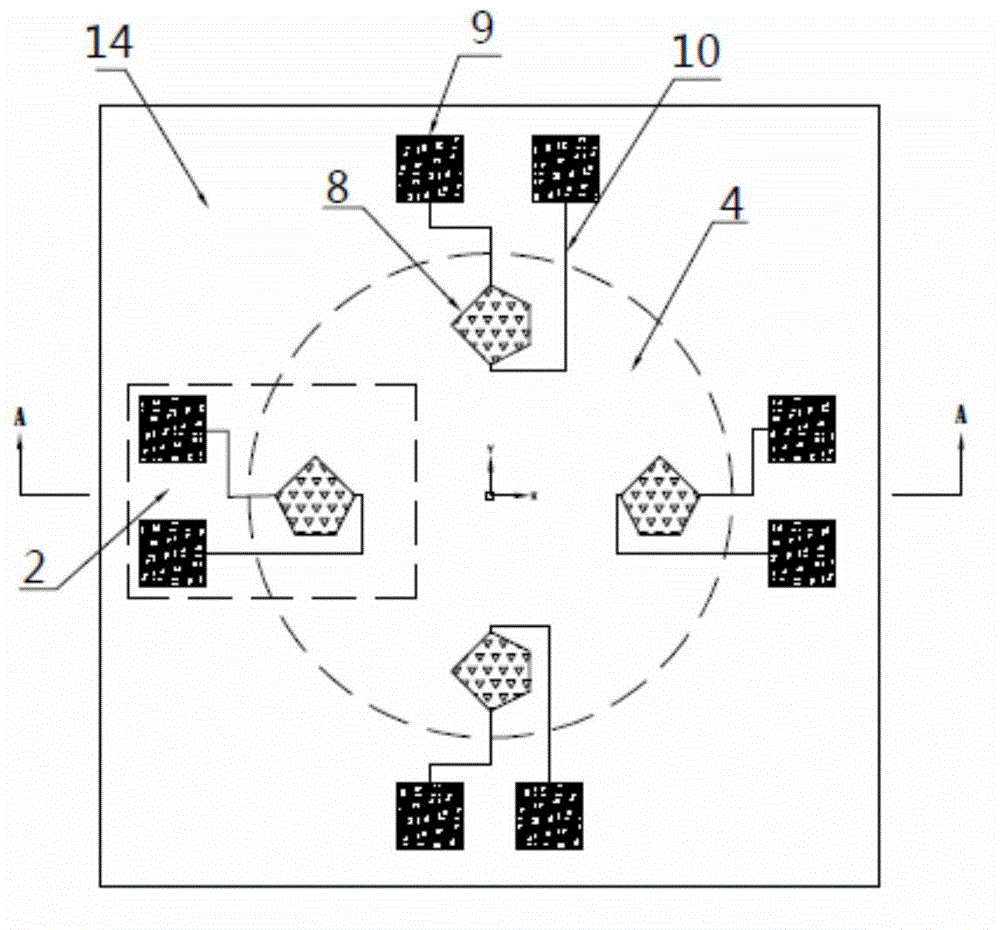

[0032] like Figure 1(a)-1(d) and figure 2 Shown are respectively the top view structure schematic diagram and the side view structure schematic diagram in the present invention.

[0033] The micro microphone of the FBAR structure on the diaphragm comprises a base, a detection element 2 and a composite elastic support layer 14, the base is located below the composite elastic support layer 14, and the detection element 2 is located above the composite elastic support layer 14, and the composite elastic support layer 14 is used for Support the detection element 2; the base includes a Si base 3 and a cavity 5, the shape of the Si base 3 is a cuboid, and a trumpet-shaped through hole is arranged in the middle of the Si base 3, and the end of the through hole with a smaller diameter is located on the Si base 3, the upper surface of the Si base 3 is close to the lower surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com