Detachable glass sand core dialysis device

A glass sand core and dialysis device technology, applied in dialysis, etc., can solve the problems of rising dialysis costs, swelling and cracking of dialysis bags, and increased volume of retained fluid, etc., and achieves the advantages of easy cleaning and sterilization, small environmental impact, and low cost of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

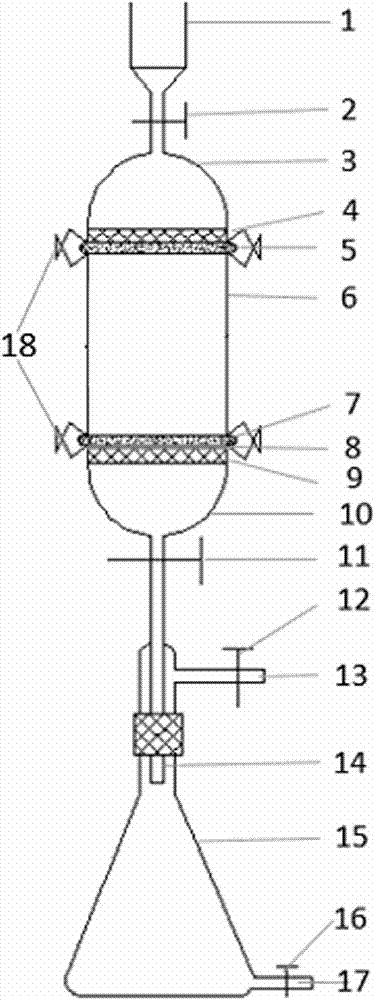

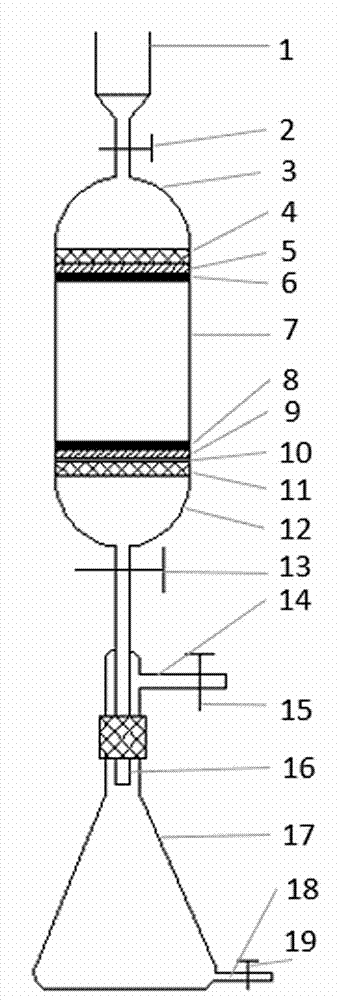

Method used

Image

Examples

Embodiment 1

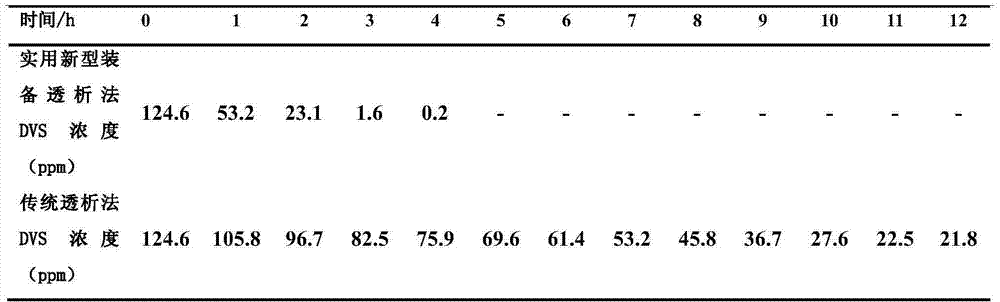

[0023] Example 1: Divinylsulfone (DVS) cross-linked sodium hyaluronate gel was dialyzed using the dialysis device of the present invention to remove unreacted cross-linking agent. The upper and lower liquid storage tanks use G5 type glass sand cores, and the lower liquid storage tank is covered with a dialysis membrane with a molecular weight cut-off of 0.5KDa. Put the cross-linked sodium hyaluronate gel block that has been cross-linked into the dialysis tank, use the pre-configured phosphate buffer solution (PBS) as the dialysate, open the outlet knob of the lower liquid storage tank, and open the pressure reducing valve , Carry out dialysis under reduced pressure conditions (0.1MPa), take off the exudate flowing out from the liquid storage tank at regular intervals, and analyze the residual concentration of the cross-linking agent DVS in the exudate. In addition, the traditional dialysis bag method was used for dialysis comparison, and samples in the dialysis bag were taken ...

Embodiment 2

[0028] Example 2: Dialyzing the acid-treated collagen solution with pH=3.3 by using the dialysis equipment of the present invention to adjust the pH to neutral. The upper and lower liquid storage tanks use G2 type glass sand cores, and the lower liquid storage tank is covered with a dialysis membrane with a molecular weight cut-off of 0.2KDa. Put the cross-linked sodium hyaluronate gel block that has been cross-linked into the dialysis tank, dialyze with deionized water with a pre-configured pH=7.0, open the outlet knob of the lower liquid storage tank, and perform dialysis under normal pressure conditions , starting from dialysis with deionized water, remove the exudate from the storage tank at regular intervals, and analyze the pH value of the exudate. In addition, the traditional dialysis bag method was used for dialysis comparison. From the beginning of dialysis, samples in the dialysis bag were taken at regular intervals to analyze the pH value of the exudate. The test r...

Embodiment 3

[0031] Embodiment 3: adopt the dialysis equipment of the present invention, carry out dialysis to the polymethyl methacrylate that atom transfer radical polymerization (ATRP) method obtains, to remove Cu in the catalyst 2+ . The upper and lower liquid storage tanks use G3 type glass sand cores, and the lower liquid storage tank is covered with a dialysis membrane with a molecular weight cut-off of 0.1KDa. Put the polymerized polymethyl methacrylate into the dialysis tank, use the pre-prepared absolute ethanol as the dialysate, open the liquid outlet knob of the lower liquid storage tank, open the pressure reducing valve, and under the reduced pressure condition (0.1MPa ) for dialysis, remove the exudate from the storage tank at regular intervals, and analyze Cu in the exudate 2+ residual concentration. In addition, the traditional dialysis bag method was used for dialysis comparison, and samples in the dialysis bag were taken at regular intervals to analyze Cu 2+ residual c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com