Control method for submerged-arc welding platform for intersection-line seam of thick-wall large-size cylindrical weld element

A welding platform and control method technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low production efficiency, few types of weldments, narrow size range, etc., to meet the welding error, improve the welding quality, Great application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

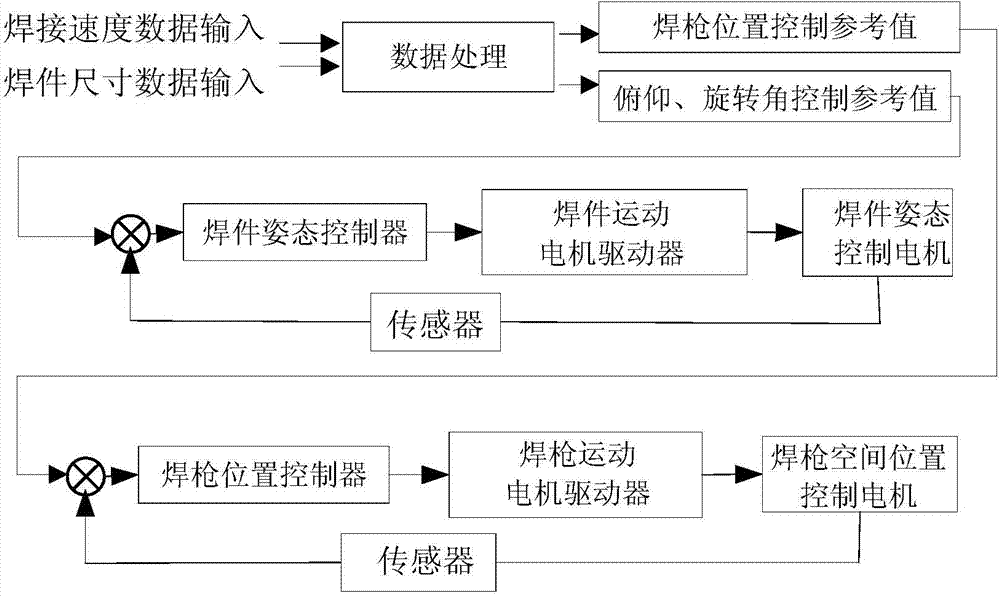

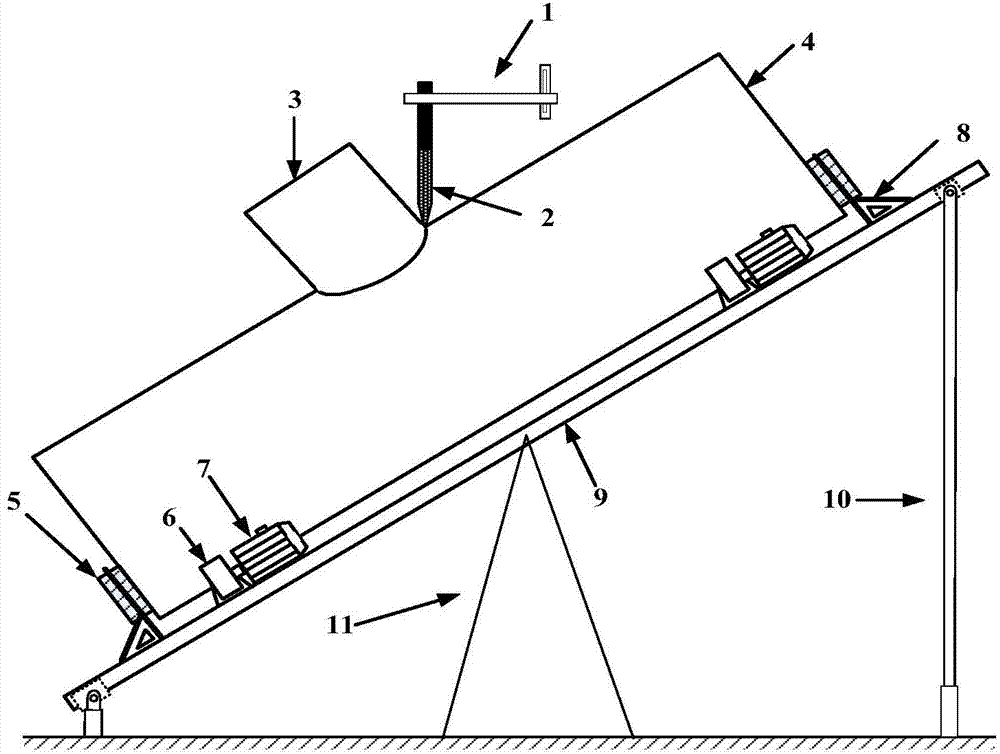

[0026] Such as figure 1 As shown, the control method of the submerged arc welding welding platform for intersecting line seams of medium-thick-walled large-size cylindrical weldments in the present invention, the implementation steps are as follows:

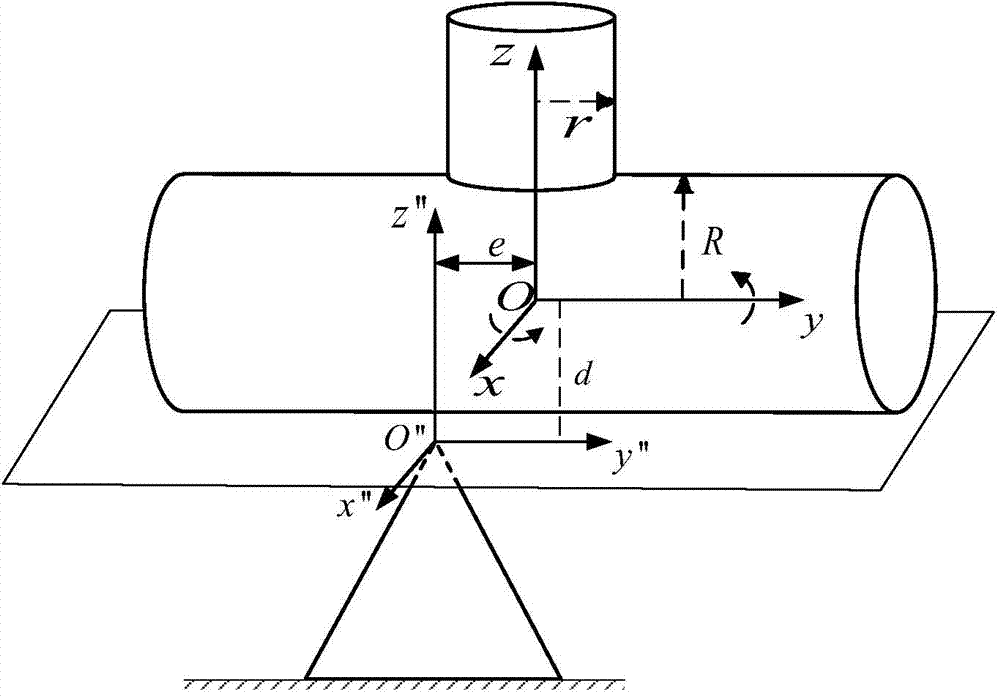

[0027] (1) Definition of coordinate system. Such as image 3 As shown, first establish a space coordinate system OXYZ, and the OXYZ coordinate system takes the intersection of the axes of the large and small weldments as the origin O. The axis of the large weldment is horizontal and the axis of the small weldment is vertical, which is defined as the initial posture of the weldment. The axes of the large and small weldments that define the initial posture are the Y axis and the Z axis, and the X axis is perpendicular to the YOZ plane. During the welding process, the relative position of the OXYZ coordinate system and the weldment remains unchanged, and changes with the change of the weldment posture. Taking the intersection po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com