UV printing full-automatic bag-making filling and sealing machine

A filling and sealing machine, fully automatic technology, applied in the direction of printing machines, printing, general parts of printing machinery, etc., can solve the problems of printing peeling, peeling pollution, foreign matter adhesion, etc., to reduce printing costs, avoid medication errors, and print clearly clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

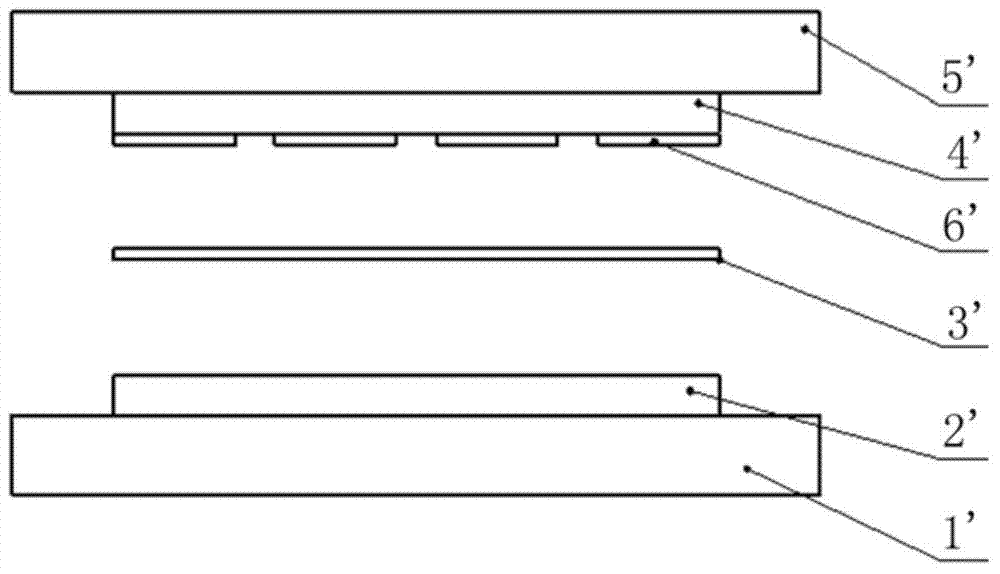

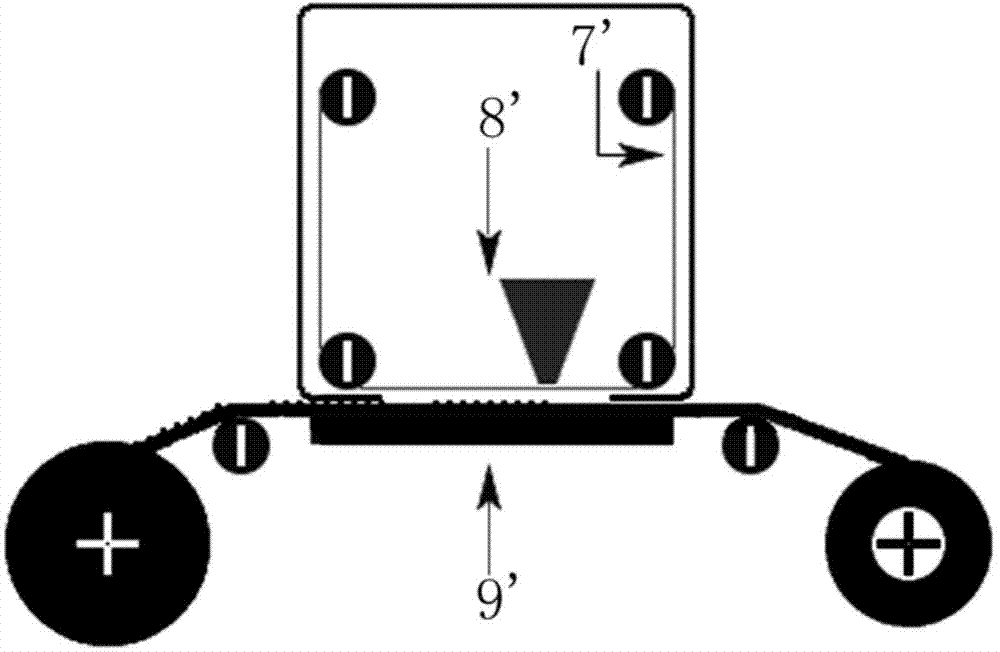

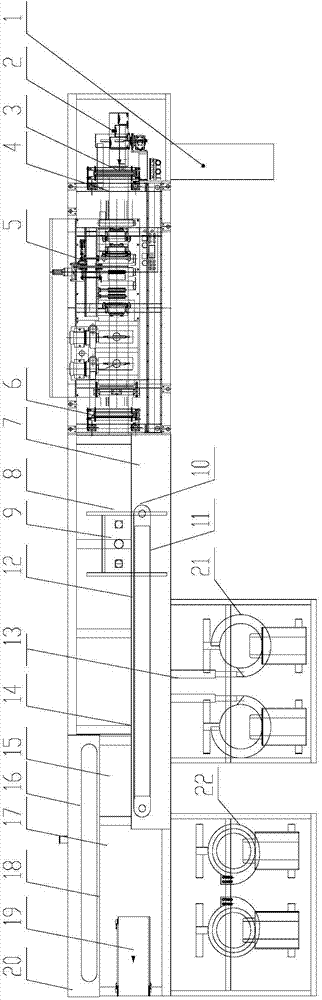

[0037] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] UV is the English abbreviation of Ultra-Violet Ray. The wavelength of ultraviolet rays required for UV printing is 100nm to 400nm, which can be subdivided into three bands (UVA, UVB, UVC); the curing of UV inks containing pigments mainly uses UVA The band, while the curing of transparent UV ink mainly uses the UVC band.

[0039] The pigments and additives used in UV ink and oil-based ink are the same, and the mixing ratio is also the same, but the oil-based ink contains about 30% light oil, which has the problem of TVOC (total volatile organic compounds), and is not suitable for application in the pharmaceutical manufacturing process. That is, gravure printing must use organic solvents, while UV printing does not use organic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com