A kind of transparent glass-ceramic composite bead material and preparation method thereof

A technology of ceramic composite and transparent glass, which is applied in the field of transparent glass-ceramic composite bead materials, can solve the problems of no further research, loss of reflective properties, mechanical toughness and reflective life can not better meet the material performance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

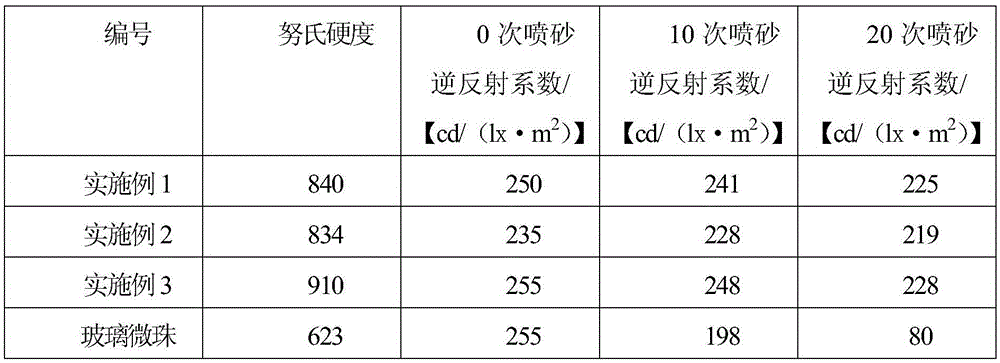

Examples

Embodiment 1

[0024] The system composition of described glass microsphere is: TiO 2 48wt%, BaO24wt%, ZnO16.5wt%, ZrO 2 10wt%, SiO 2 1wt%, CaO0.5wt%, among them, ZnO+ZrO 2 <30wt%; the particle size of the glass microspheres is 10-20 microns.

[0025] The composition of described ceramic material is: by molar ratio, ZrO 2 1. SiO2 2 0.1, Al 2 o 3 0.2, MgO0.05, Y 2 o 3 0.02.

[0026] Prepare as follows:

[0027] (1) Weigh a certain amount of glass microspheres and immerse them in acetone, ultrasonically clean them for 1 hour and then dry them for use;

[0028] (2) Weighing zirconium acetate solution, silica sol, alumina sol, magnesium acetate solution and yttrium nitrate solution in proportion, stirring to obtain a mixed sol solution, evaporating, and adjusting the sol solution to a solid content of 34-39wt%;

[0029] (3) adding the dried glass microspheres to the solution of step (2), and ultrasonically dispersing for 30 minutes to obtain a suspension;

[0030] (4) Drop the suspen...

Embodiment 2

[0034] The system composition of described glass microsphere is: TiO 2 47wt%, BaO25wt%, ZnO14wt%, ZrO 2 12wt%, SiO 2 0.5wt%, CaO0.5wt%, among them, ZnO+ZrO 2 <30wt%; the particle size of the glass microspheres is 10-20 microns.

[0035] The composition of described ceramic material is: by molar ratio, ZrO 2 2. SiO2 2 0.2,Al 2 o 3 0.4, MgO0.1, Y 2 o 3 0.15 The calcination temperature is 950° C., the calcination time is 2 hours, and the other process steps are the same as in Example 1.

Embodiment 3

[0037] The system composition of described glass microsphere is: TiO 2 49wt%, BaO34wt%, ZnO12wt%, ZrO 2 4wt%, SiO 2 0.5wt%, CaO0.5wt%, among them, ZnO+ZrO 2 <30wt%; the particle size of the glass microspheres is 10-20 microns.

[0038] The composition of described ceramic material is: by molar ratio, ZrO 2 1.5, SiO 2 0.12, Al 2 o 3 0.3, MgO0.08, Y 2 o 3 0.1 The calcination temperature is 1000° C., the calcination time is 2 hours, and other process steps are the same as in Example 1.

[0039] Process step is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com