A high weather resistance magnetic ring

A magnetic ring and high weather resistance technology, applied in the field of high weather resistance magnetic ring, can solve the problems of magnetic ring resistance to ozone, aging resistance and chemical resistance, etc., to reduce the weight of finished products, reduce its own weight, and reduce the weight of the whole vehicle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

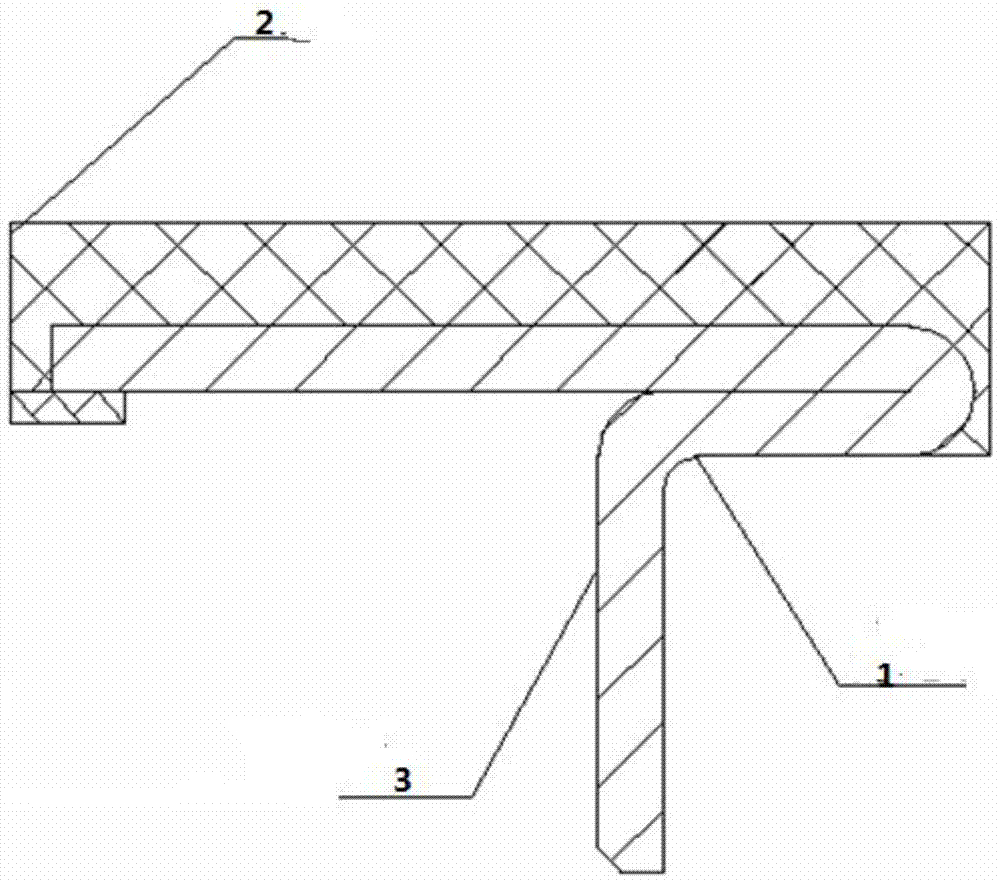

[0037] In order to make the technical means of the product produced by the present invention and reach the purpose and effect easy to understand, combine below figure 1 Concrete diagram, further elaborates this patent.

[0038] like figure 1 Shown:

[0039] A highly weather-resistant magnetic ring, the magnetic ring includes a modified rubber-plastic layer 2 containing ferrite material and a metal ring skeleton 1, and the modified rubber-plastic layer 2 containing ferrite material is wrapped in the On the metal ring skeleton 1, the modified rubber and plastic layer 2 containing ferrite material can continuously emit signals perpendicular to the N / S poles of the rubber and plastic layer after being activated.

[0040] The modified rubber and plastic layer containing ferrite material includes the following raw materials in weight percentage:

[0041] 6% PVC / NBR rubber and plastic material,

[0042] 86% ferrite powder,

[0043] 5% PVC material,

[0044] 1.5% dispersant,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com