Imitation jean knitted wool fabric and making method thereof

A technology for imitating denim and fabrics, which is applied in knitting, weft knitting, and fabric surface trimming, etc. It can solve the problems of easy washing and tearing, low yarn strength, and easy detachment, and achieves small fabric loss, strong raw material adaptability, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

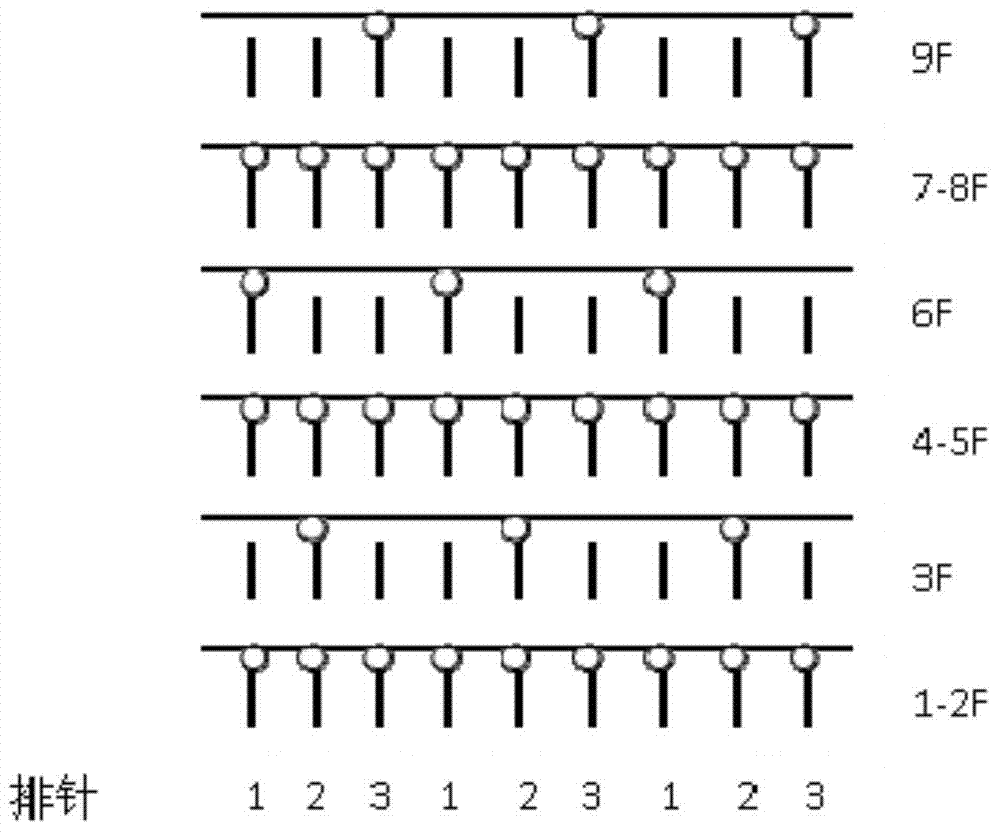

[0024] Denim-like knitted wool fabric with a weaving structure such as figure 1 , is a single-jersey jacquard weave with 9 channels and one cycle. The 1st, 2nd, 4th, 5th, 7th, and 8th channels are plain stitches, knitted with wool yarn and lined with spandex yarns, and the 3rd, 6th, and 9th channels are Jacquard weave, woven pure cotton white yarn.

[0025] The yarns used are: 60N / 2 double-threaded blue shrink-resistant wool yarn, 32S / 1 combed cotton yarn, and 40D low-temperature LYCRA (OU040D105).

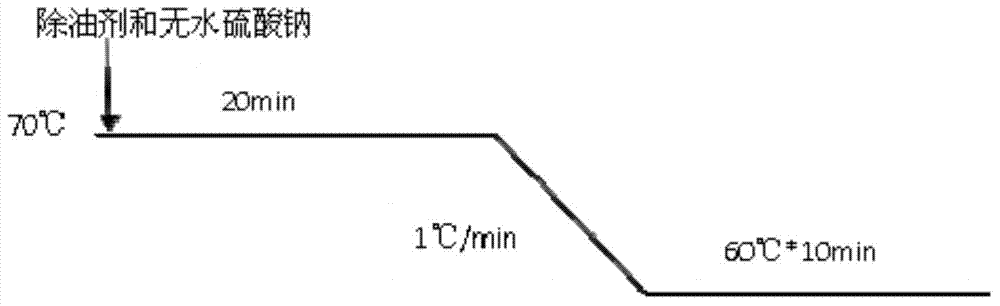

[0026] The preparation method includes the following steps:

[0027] 1. Weaving process

[0028] Braided structure: such as figure 1 shown;

[0029] Machine model: 30-inch 24G96 Meyer four-track single-sided circular knitting machine;

[0030] Thread length: wool color yarn length is 27.9cm / 100 needles, pure cotton white yarn length is 15.8cm / 100 needles, low temperature LYCRA thread length is 11.3cm / 100 needles;

[0031] Speed: 18rmp; Drop machine weight: 275g / m 2 , land...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com