Surrounding rock reinforcement machine

An all-in-one, reinforcement technology, applied in the field of rock mass grouting engineering machinery and equipment, construction engineering machinery, can solve the problems of grouting body tearing, large difference, poor permeability, etc., to achieve rapid pulping, easy cleaning, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

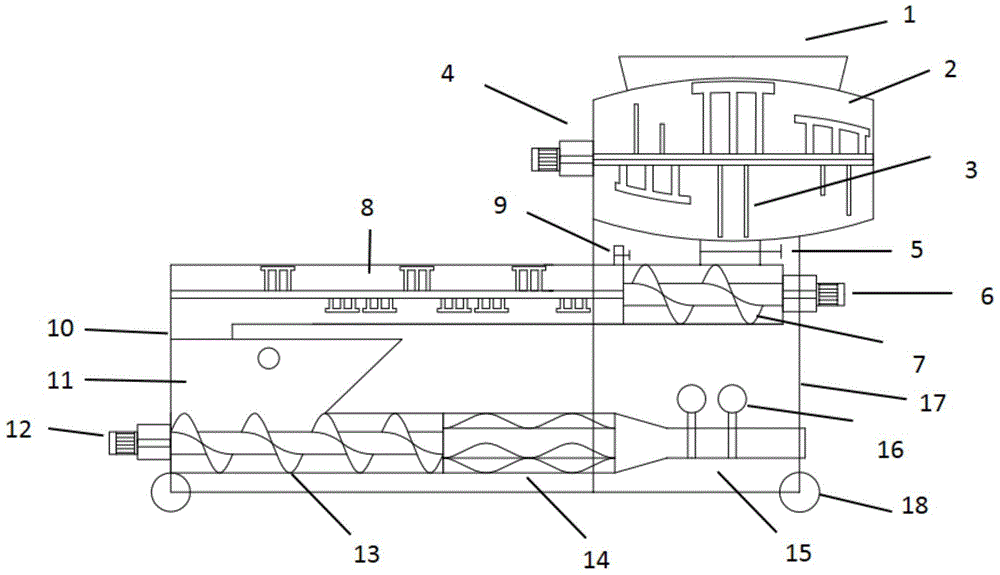

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] Firstly, the names of the parts represented by the reference numerals in the drawings of the specification will be introduced.

[0040] 1 feed hopper,

[0041] 2 dry powder mixing buckets,

[0042] 3 dry powder mixing blades,

[0043] 4 motors,

[0044] 5 feed rollers,

[0045] 6 pulping motors,

[0046] 7 first auger feeding shaft,

[0047] 8 pulping shafts,

[0048] 9 water inlet valve,

[0049] 10 outlet,

[0050] 11 storage hopper,

[0051] 12 grouting motors,

[0052] 13 Second auger feeding shaft,

[0053] 14 screw grouting pump,

[0054] 15 slurry outlet,

[0055] 16 sensors,

[0056] 17 brackets,

[0057] 18 Move the axle.

[0058] Detailed exemplary embodiments are disclosed below. However, specific structural and functional details disclosed herein are merely for purposes of describing example embodiments.

[0059] It should be unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com