Plasma and electrostatic adsorption coupled automobile emission purifier and purification method

A technology of plasma and automobile exhaust, applied in the direction of exhaust devices, machines/engines, noise reduction devices, etc., can solve the problems of poor processing effect and poor versatility, and achieve the goal of increasing adsorption efficiency, enhancing processing effect, and improving real-time processing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

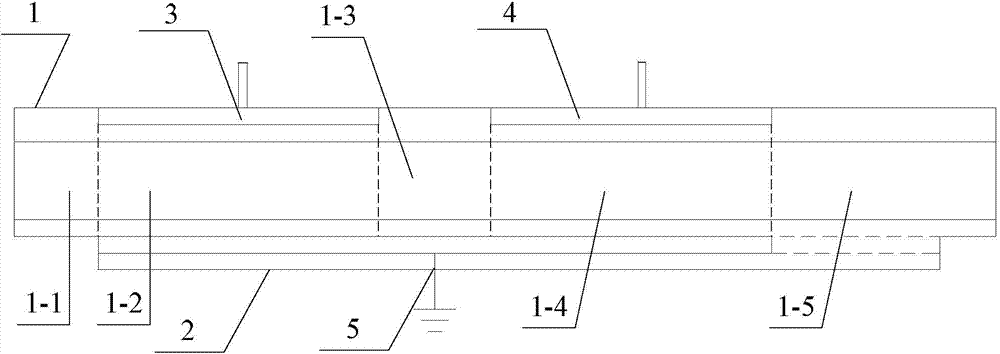

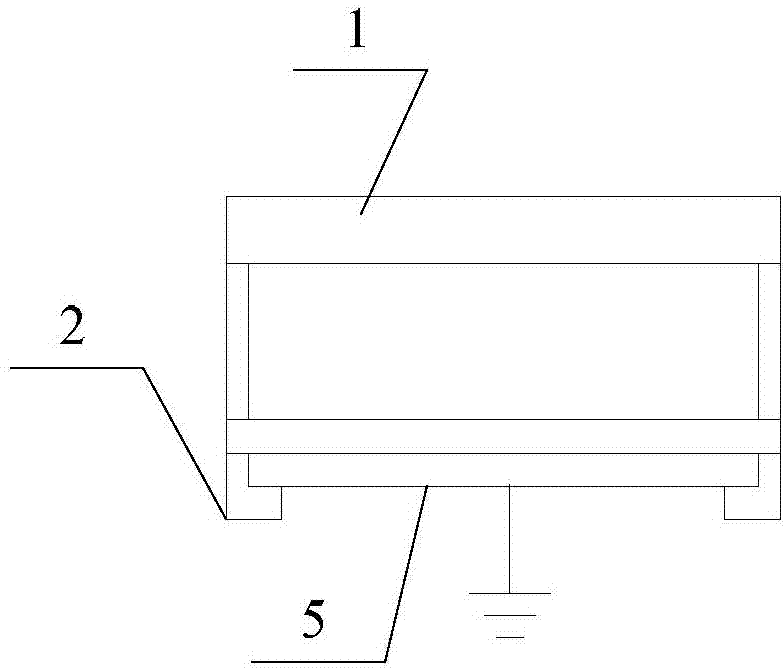

[0028] Specific implementation mode one: the following combination figure 1 with figure 2 Describe this embodiment, the vehicle exhaust gas purifier coupled with plasma and electrostatic adsorption described in this embodiment is characterized in that it includes an exhaust gas purification pipe 1, a glass slide 2, a sinusoidal high voltage electrode 3, a DC high voltage electrode 4 and a ground electrode 5,

[0029] The tail gas purification pipe 1 is a non-metallic rectangular parallelepiped pipe. The tail gas purification pipe 1 is divided into tail gas introduction area 1-1, plasma treatment area 1-2, transition area 1-3, electrostatic dust removal area 1-4 and Cooling devices are installed in tail gas discharge area 1-5 and tail gas introduction area 1-1;

[0030] The glass slideway 2 is fixed on the outer surface of the bottom surface of the exhaust gas purification pipe 1, and the ground electrode 5 is slidably arranged on the glass slideway 2;

[0031] The sinusoid...

specific Embodiment approach 2

[0034] Embodiment 2: In this embodiment, Embodiment 1 is further described, and the tail gas purification pipe 1 is a quartz glass pipe.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment further describes Embodiment 1 or 2. The power supply voltage connected to the sinusoidal high-voltage electrode 3 is 10kV-30kV, and the frequency is 10000Hz-30000Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com