Polytetrafluoroethylene traction pipe

A technology of polytetrafluoroethylene and traction pipes, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of pipe flattening, long construction period, and difficult construction, so as to improve work efficiency, Time-saving, high efficiency and good plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

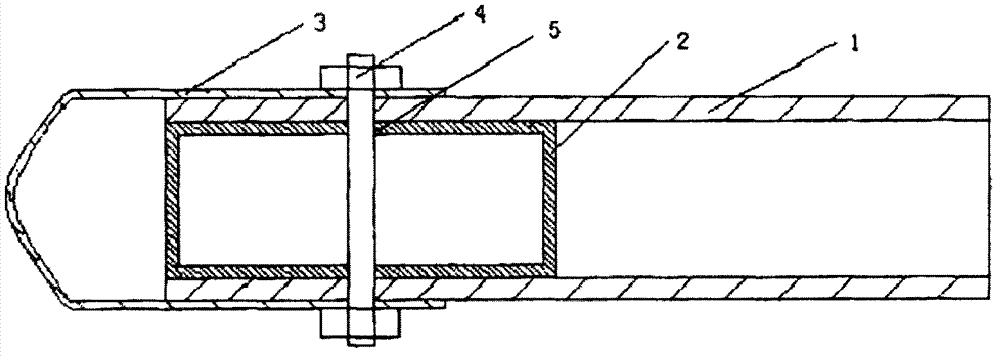

[0021] Such as figure 1 As shown, the traction tube provided by the present invention includes an outer tube 1, a cylindrical plugging head 2, a U-shaped traction ring 3, and a core bolt 4, wherein the outer diameter and wall thickness of the outer tube 1 are the same as those of the towed PTFE The ethylene pipe is the same, the outer pipe 1 is made of modified polypropylene polytetrafluoroethylene material, the cylindrical plug head 2 is made of steel, and the wall thickness is 10-20 mm. The U-shaped traction ring 3 is made of steel, with a thickness of 7-12 mm and a width of 30-40 mm. If the outer diameter of the towed pipe is large or the traction resistance is too large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com