Stratospheric airship electronic equipment cabin temperature control system and control method

A temperature control system, the technology of stratospheric airship, is applied in the direction of using electric mode for temperature control, auxiliary controller with auxiliary heating device, etc., which can solve the problems affecting the performance of equipment, low mass flow, insufficient cooling capacity, etc. Achieve the effect of preventing insufficient cooling capacity, high safety and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

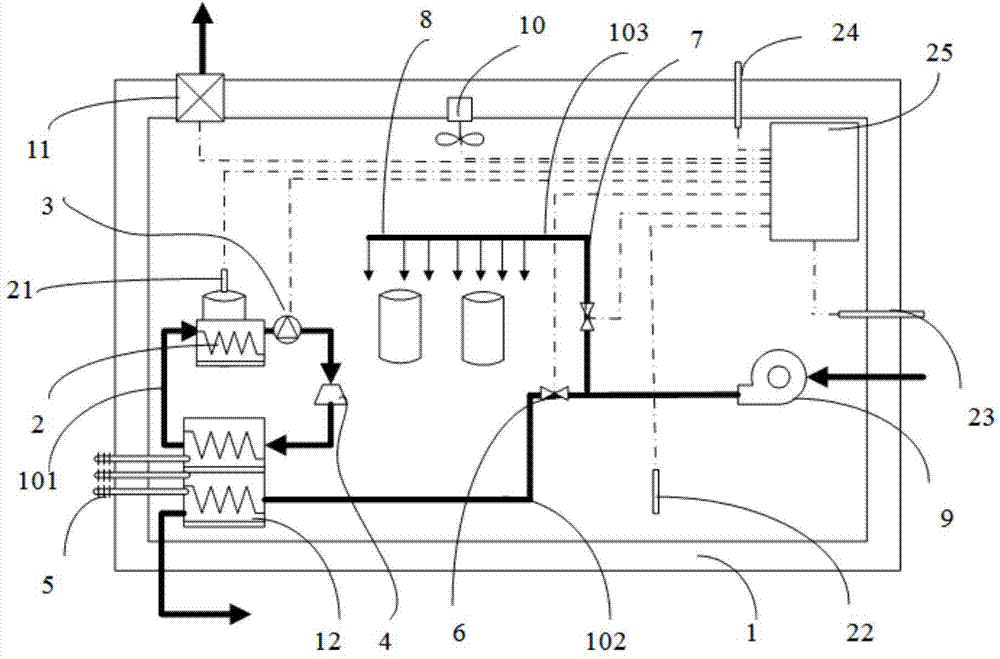

[0022] Such as figure 1 As shown, a stratospheric airship electronic equipment compartment temperature control system of the present invention includes a phase change heat storage subsystem, a liquid circulation subsystem and a fan cooling subsystem;

[0023] The phase-change heat storage subsystem includes a phase-change heat exchanger and a heat pipe installed in the phase-change heat exchanger. The interior of the phase-change heat exchanger is filled with phase-change materials. The radiation heat transfer and convective heat transfer of the environment transfer the heat inside the phase change heat storage subsystem to the outside world;

[0024] The liquid circulation subsystem includes a heat exchanger, a pump, and a liquid reservoir located in the electronic equipment compartment, and the heat exchanger, pump, liquid reservoir, and phase-change heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com