Material transport cart

A technology for transporting vehicles and materials, applied in the direction of goods transporting vehicles, transporting objects, transportation and packaging, etc., can solve the problems of short service life, small transportation volume, wheel slippage and unable to travel, and achieve long service life, low maintenance cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

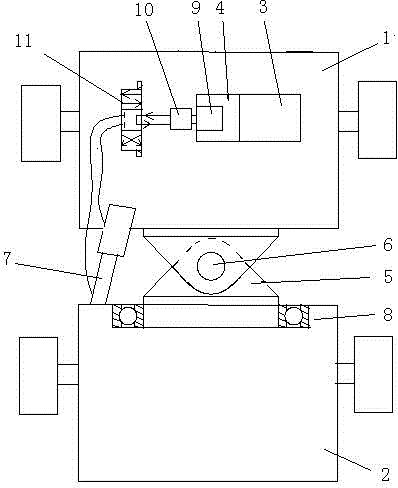

[0011] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a headstock 1 and a hopper 2, and there are power devices such as an engine 3 and a gearbox 4 with a power take-off 9 inside the headstock. connected, and one side is provided with a hydraulic cylinder 7 that is connected to the hydraulic system to control the steering. .

[0012] The output shaft of the power take-off 9 is connected to a hydraulic pump 10, and the hydraulic pump is connected to a hydraulic cylinder through a three-position four-way electromagnetic reversing valve 11.

[0013] The hydraulic cylinder 7 is a double-acting hydraulic cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com