Oilfield Waste Oil Recovery Electromagnetic Steam Integrated Device

A technology of sewage oil recovery and integrated device, applied in steam generation, steam generation method, water/sewage multi-stage treatment, etc., can solve the problems of affecting liquid flow, low heating efficiency, low head pressure, etc. The effect of fast heating speed and high external pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

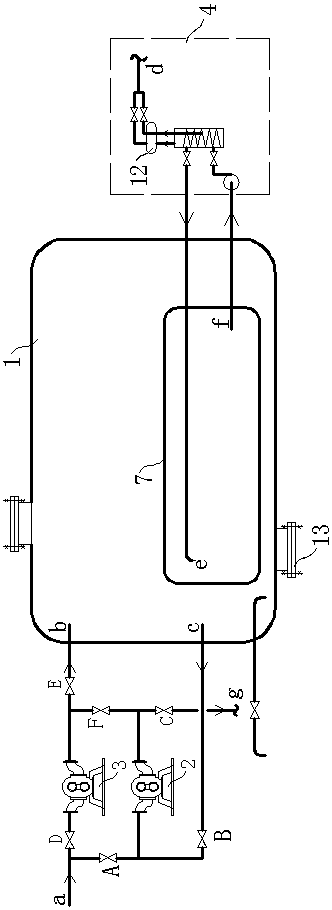

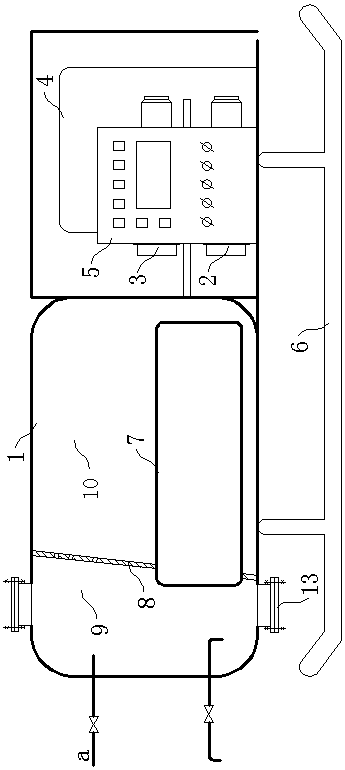

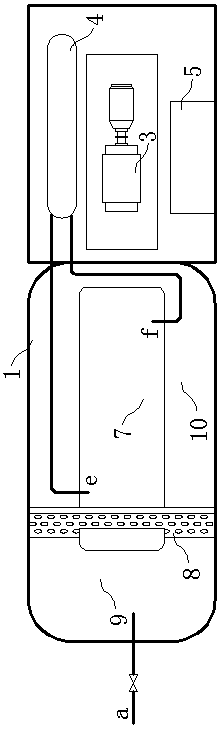

[0016] Below in conjunction with accompanying drawing, the oilfield waste oil reclaiming electromagnetic steam integrated device of the present invention is further described:

[0017] The electromagnetic steam integrated device for recovering oilfield waste oil of the present invention is composed of a waste oil treatment tank 1 , a material pump I2 , a material pump II3 , a boiler 4 and an instrument control box 5 .

[0018] The waste oil treatment tank 1, the material pump I2, the material pump II3, the boiler 4 and the instrument control box 5 are assembled on the flat plate of the skid base 6, and the waste oil treatment tank 1, The instrument control box 5, the material pump I2, the material pump II3 and the boiler 4 are installed side by side at the other end in sequence, and the waste oil treatment tank 1 at the front end is adjacent to each other. Wherein the material pump I2, the material pump II3, the boiler 4 and the instrument control box 5 can also be centrally a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com