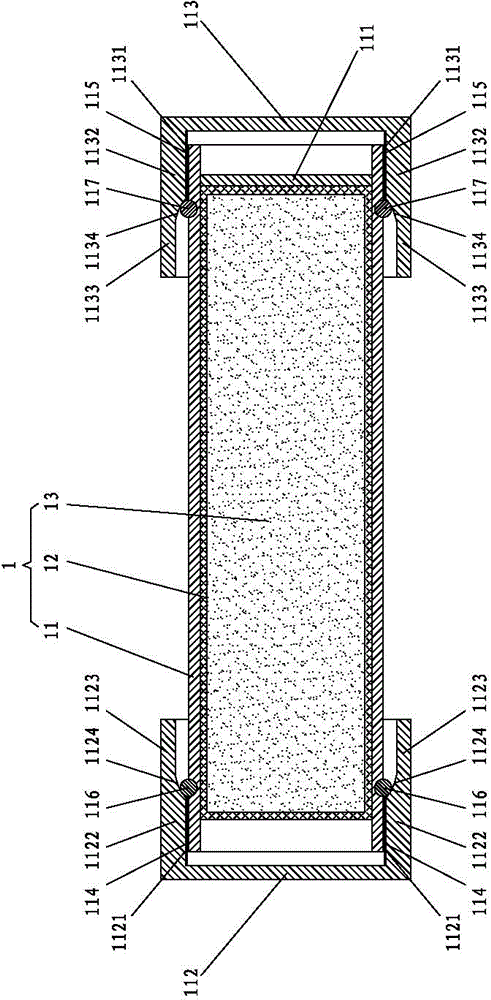

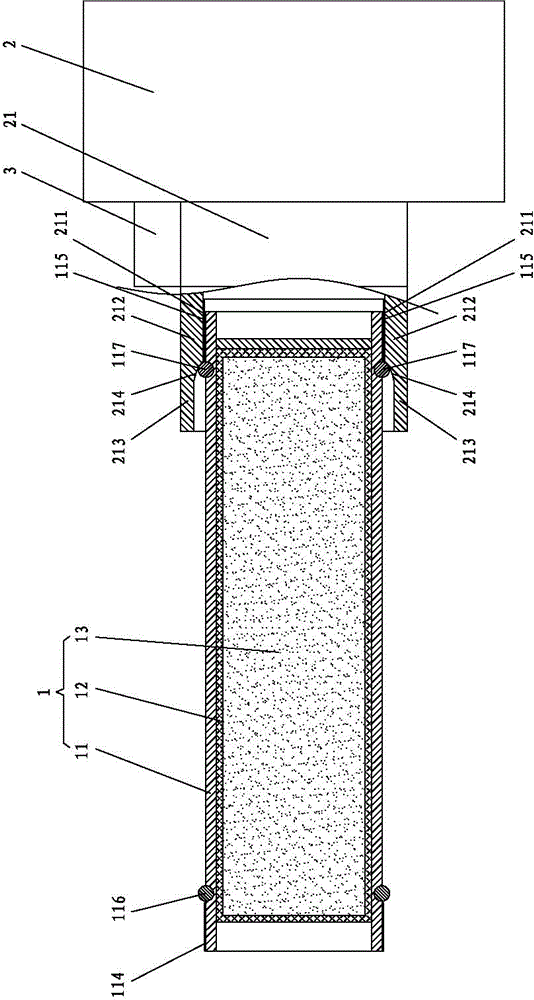

Method for simply detecting lead content in working environment and sampling device

A technology of working environment and sampling device, which is applied in sampling device, preparation of test samples, and analysis using chemical indicators, etc., can solve the problems of sampling pollution, failure, and poor sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment one, comprises the steps:

[0063] (1) Pass 1 cubic meter of air through the sampling device at the job site, and use the sampling device to absorb lead particles in the air for sampling;

[0064] (2) Take out the absorber that absorbs lead-containing particles in the sampling device, and soak it in a bottle containing a mixed solution of sulfuric acid with a concentration of 50g / L and sodium chloride with a concentration of 120g / L, and wash all the lead-containing particles. Then take out the absorber and rinse the absorber with another mixed solution of sulfuric acid and sodium chloride, and let all the solution flowing down from the rinse flow into the bottle, so that the lead ions can be in the mixed solution as much as possible;

[0065] (3) In order to enhance the dissolution efficiency of lead ions, in a water bath at 80°C, use ultrasonic waves with a frequency of 18khz to pulverize and disperse the lead-containing particles in the bottle 10 times, 4 s...

Embodiment 2

[0069] Embodiment two, comprises the steps:

[0070] (1) Pass 1.5 cubic meters of air through the sampling device at the job site, and use the sampling device to absorb lead particles in the air for sampling;

[0071] (2) Take out the absorber that absorbs lead-containing particles in the sampling device, and soak it in a bottle containing a mixed solution of sulfuric acid with a concentration of 65g / L and sodium chloride with a concentration of 135g / L, and wash all the lead-containing particles. Then take out the absorber and rinse the absorber with another mixed solution of sulfuric acid and sodium chloride, and let all the solution flowing down from the rinse flow into the bottle, so that the lead ions can be in the mixed solution as much as possible;

[0072] (3) In order to enhance the dissolution efficiency of lead ions, in a water bath at 85°C, use ultrasonic waves with a frequency of 19.5khz to pulverize and disperse the lead-containing particles in the bottle 8 times,...

Embodiment 3

[0076] Embodiment three, comprises the steps:

[0077] (1) Pass 2 cubic meters of air through the sampling device at the job site, and use the sampling device to absorb lead particles in the air for sampling;

[0078] (2) Take out the absorber that absorbs lead-containing particles in the sampling device, and soak it in a bottle containing a mixed solution of sulfuric acid with a concentration of 80g / L and sodium chloride with a concentration of 150g / L, and wash all the lead-containing particles. Then take out the absorber and rinse the absorber with another mixed solution of sulfuric acid and sodium chloride, and let all the solution flowing down from the rinse flow into the bottle, so that the lead ions can be in the mixed solution as much as possible;

[0079] (3) In order to enhance the dissolution efficiency of lead ions, in a water bath at 90°C, use ultrasonic waves with a frequency of 21khz to pulverize and disperse the lead-containing particles in the bottle 6 times, 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com