Capacitive fingerprint sensor and fingerprint imaging module

A fingerprint sensor and capacitive technology, applied in the direction of acquiring/organizing fingerprints/palmprints, instruments, printing image collection, etc., can solve the problems of occupied area, high cost, and increase, so as to reduce device manufacturing cost and process complexity , The effect of reducing the difficulty of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

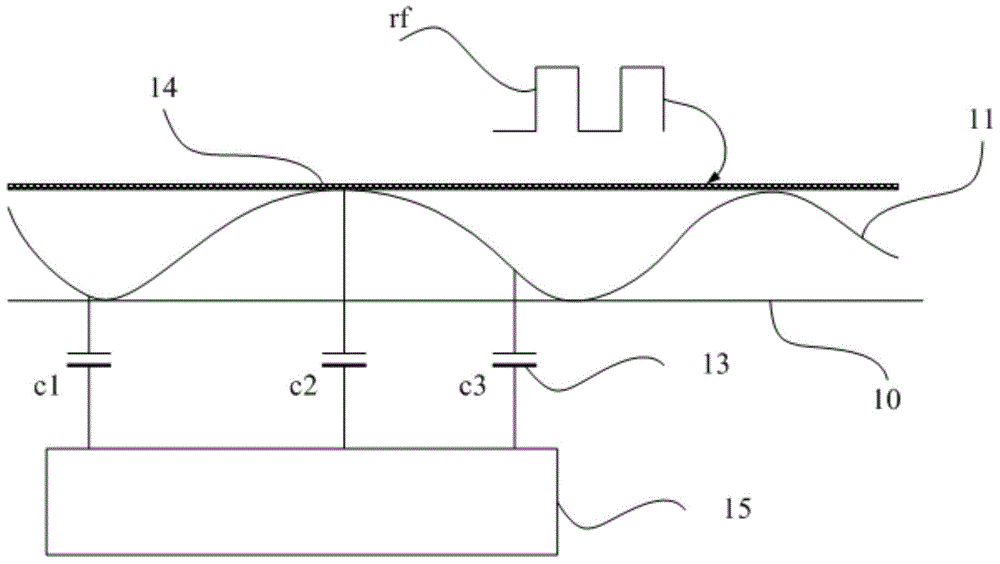

[0064] It can be known from the background art that most of the capacitive fingerprint sensors in the prior art are based on integrated circuits on silicon wafers, which often require a crystalline silicon process, so there are problems of complicated processes and high cost.

[0065] In order to solve the technical problem, the present invention provides a capacitive fingerprint sensor, including:

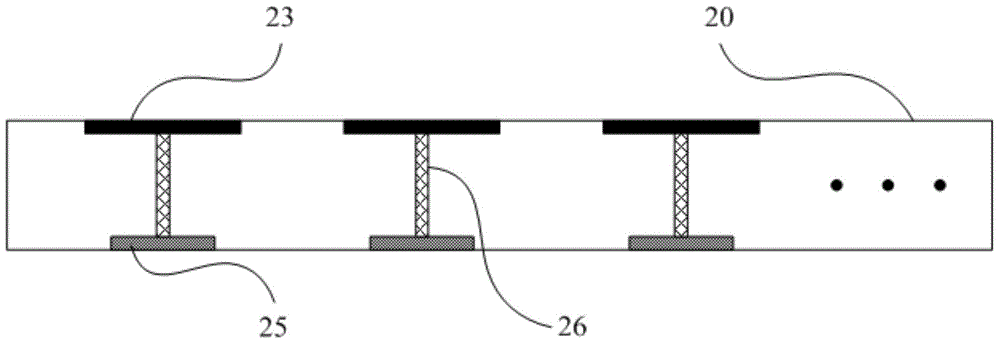

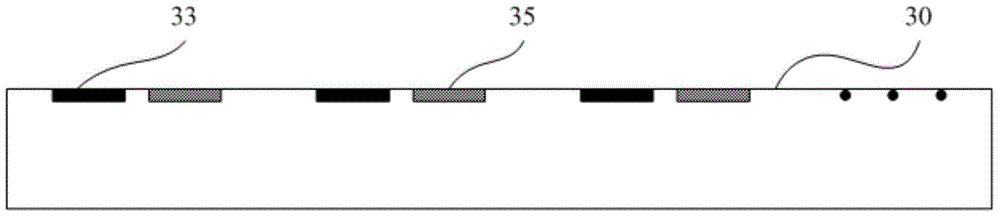

[0066] a substrate; a pixel unit arranged on the surface of the substrate in an array, the pixel unit includes an amorphous switching device, the amorphous switching device includes a control end, a first end and a second end, the first end and the first end The two terminals are turned on or off under the control of the control terminal; the pixel unit further includes a first plate connected to the first terminal of the amorphous switching device, which is used to form a capacitance structure with the fingerprint, and is also used to When the amorphous switching device is turned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com