Method for predicting ammonia nitrogen concentration in anaerobic fermentor under backflow process

A technology of anaerobic fermentation and ammonia nitrogen concentration, applied in the field of biogas engineering, can solve problems such as environmental pollution, and achieve the effect of reducing hidden risks, significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

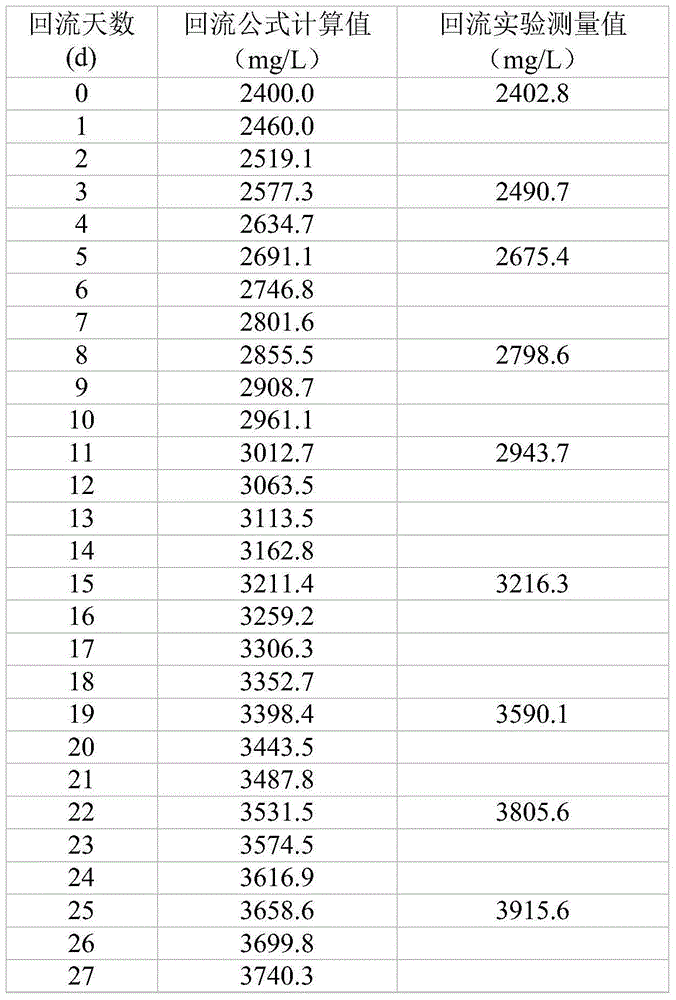

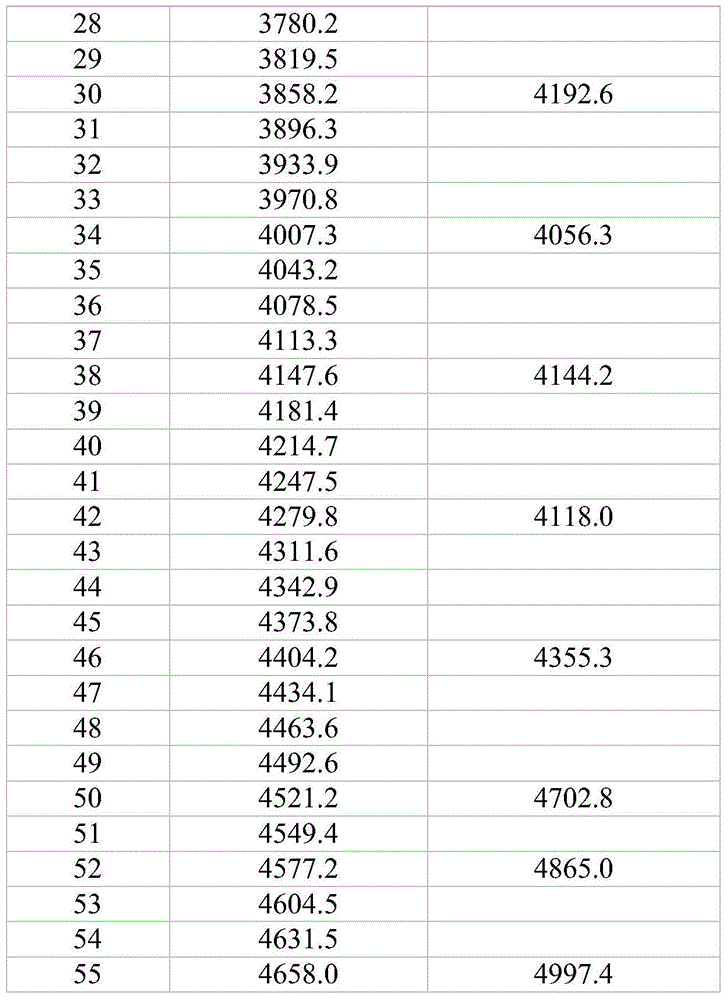

[0028] The method of the present invention will be described in detail below in conjunction with examples.

[0029] Experimental conditions: total solid content of dried chicken manure as fermentation raw material: 90%; volatile solid content: 71.4%;

[0030] Raw material nitrogen content: 4.9% / g total solid content;

[0031] Anaerobic fermentation organic load: 3g VS / L / d;

[0032] Effective volume of CSTR: 20L;

[0033] Hydraulic retention time 25d;

[0034] The daily volume of in and out materials is 0.8L;

[0035] Ammonia nitrogen content in biogas slurry under stable operating conditions before reflux: 2.4g / L

[0036] Suppose: the reflux process does not affect the conversion rate of ammonia nitrogen, then a 0 =a 1 =a 2 =…=a n

[0037] The nitrogen content of dry chicken manure added to the fermenter every day = 3*20*90%*4.9% / 71.43% = 3.7g;

[0038] a 0 =2.4*0.8 / 3.7=0.52; y 0 = 2.4; R = 0.625

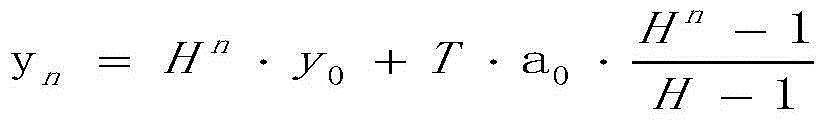

[0039] H=[20-(1-0.625)*0.8] / 20=0.985 T=3.7 / 20=0.185

[0040] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com